Internal stress measurement system and method for material based on photothermal radiation measurement

A measurement system, photothermal radiation technology, applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of low detection efficiency, expensive equipment detection accuracy, small material size, etc., to achieve Improve characteristic properties, completely non-destructive and non-contact measurement, and improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

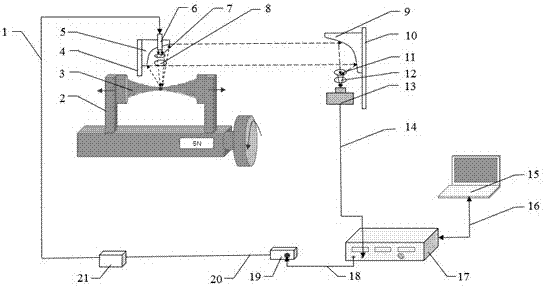

[0033] Specific implementation mode one: as figure 1 As shown, the material internal stress measurement system based on photothermal radiation measurement provided in this embodiment consists of an optical fiber 1, a manual stretching machine 2, a test sample 3, a small off-axis parabolic mirror holder 4, a small off-axis parabolic mirror 5, a quasi- Straight mirror 6, focusing mirror 7, first polarizer 8, large off-axis parabolic mirror 9, large off-axis parabolic mirror frame 10, filter 11, second polarizer 12, infrared detector (HCT, response range, 2~ 14μm) 13, the first BNC data line 14, computer 15, NI data line 16, lock-in amplifier (SR830) 17, the second BNC data line 18, 808nm laser power supply (peak power 120mW) 19, laser power supply line 20, 808nm The laser 21 is composed of a small off-axis parabolic mirror 5 installed on a small off-axis parabolic mirror holder 4, the test sample 3 is clamped on the manual stretching machine 2, the focusing mirror 7 and the firs...

specific Embodiment approach 2

[0046] Specific implementation mode 2: In this implementation mode, the test material is an aviation aluminum alloy, and the calibration sample is an aviation aluminum alloy material that has undergone aging treatment. . The steps to measure the internal stress of the material are as follows:

[0047] (1) Firstly, the calibration sample is clamped on the manual stretching machine 2 as the test sample 3, and the tension of the manual stretching machine 2 is 0 at this time;

[0048] (2) Turn on the material internal stress measurement system based on photothermal radiation measurement, this step includes turning on the computer 15, the lock-in amplifier 17, the laser power supply 19 and other equipment;

[0049] (3) The computer 15 controls the lock-in amplifier 17 and then controls the 808 nm laser 21 to emit laser light, and the power of the 808 nm laser power supply 19 is set to 20 mW;

[0050] (4) Adjust the small off-axis parabolic mirror holder 4 to focus the laser on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com