Series arrangement of hydraulic chain tensioner and ratchet

A technology of hydraulic tensioner and tensioner, which is applied in the direction of belt/chain/gear, transmission device, mechanical equipment, etc., which can solve the problems of efficiency and system durability, reduce chain preload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

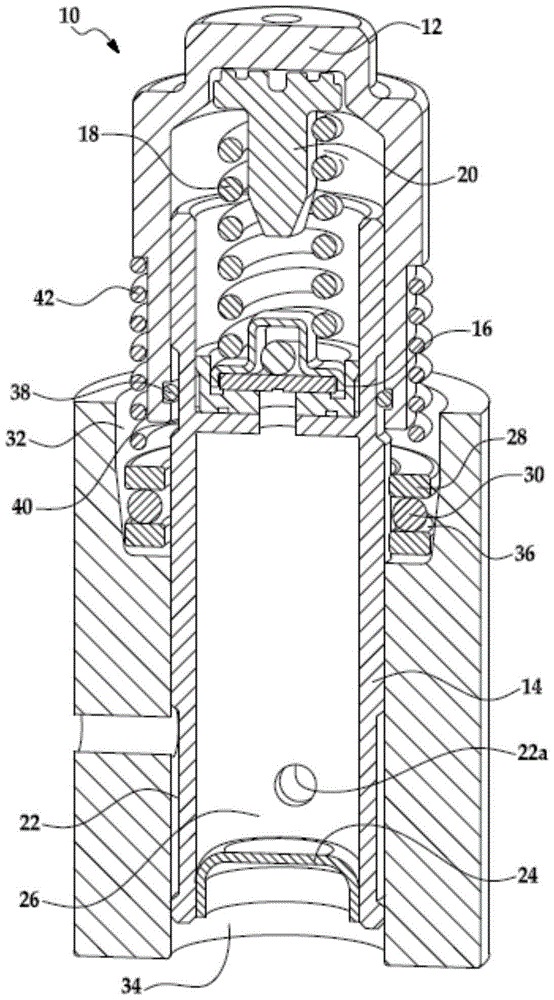

[0011] refer to figure 1 , the tensioner 10 for an annular power transmission member may include a piston 12 operatively engaged with the annular power transmission member and a cylinder 14 assembly, the piston 12 being operatively engaged with the annular power transmission member, and the cylinder 14 guiding the piston 12 to perform simultaneous motion in the direction of the annular power transmission member. The shaft slides and defines a reservoir 26 for receiving hydraulic fluid. Bearing 28 may have bearing balls 30 located in counterbore 32 coaxial with cylinder bore 34 . The counterbore 32 may have a steep taper 36 on which the bearing ball 30 rides, such that when the cylinder 14 moves in the extension direction, the bearing ball 30 moves out of the counterbore 32 to allow free extensional movement of the cylinder 14 and such that when the cylinder As the cylinder 14 moves in the retracting direction, the bearing balls 30 are driven downward into the steep cone 36 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com