Saw blade having integrated swarf space

A saw blade and space technology, applied in the field of saw blades, can solve the problems that the cutting teeth are not very resistant to bending and the cutting surface is not neat, and achieve the effect of avoiding the formation of air eddy currents and reducing running noise.

Inactive Publication Date: 2016-01-06

ALBERT KNEBEL HLDG

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with known saw blades is that the cutting teeth are not very resistant to bending and produce undesired noises due to air swirl formation

Additionally, jagged, grooved cut surfaces due to axial vibration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

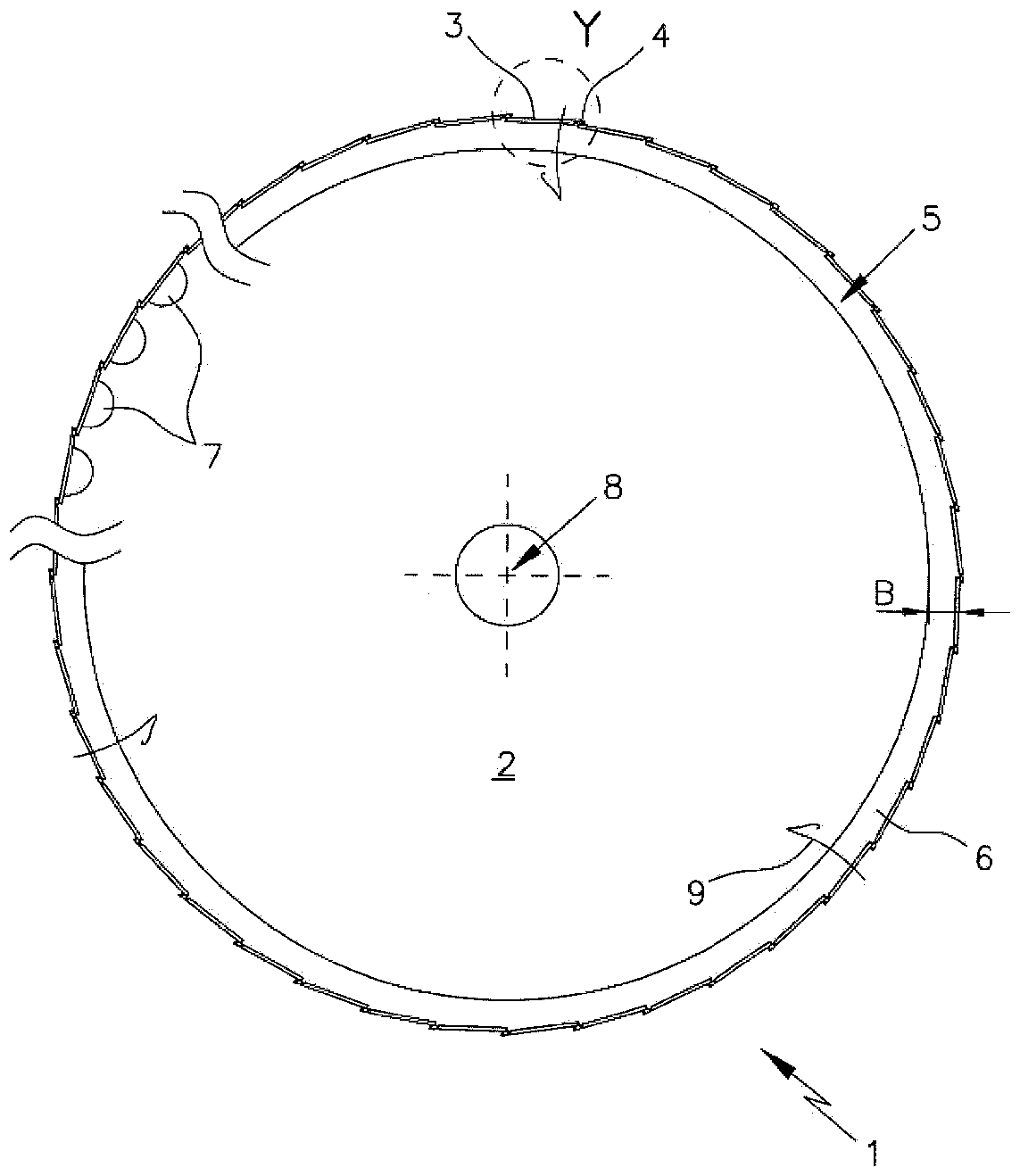

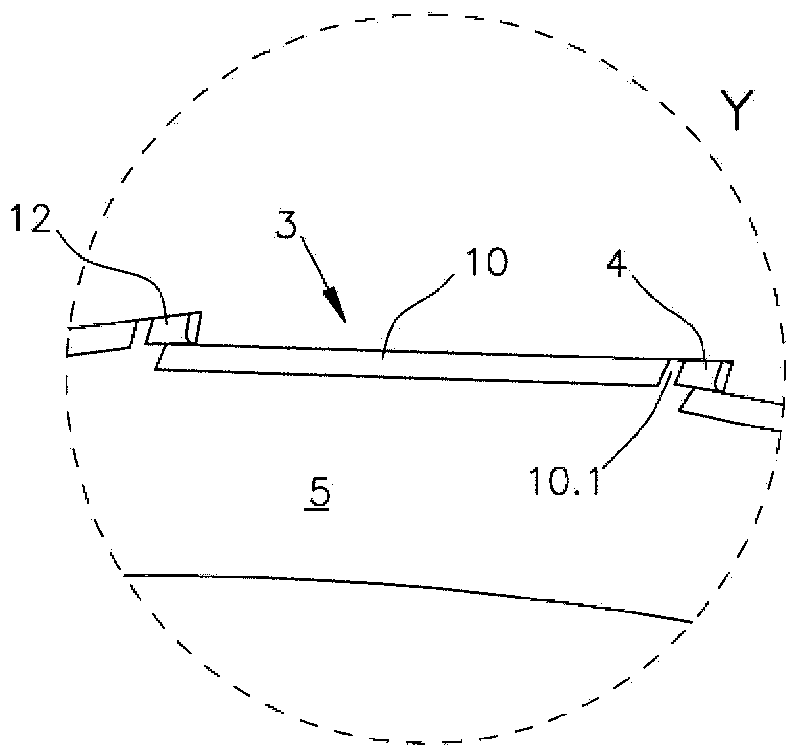

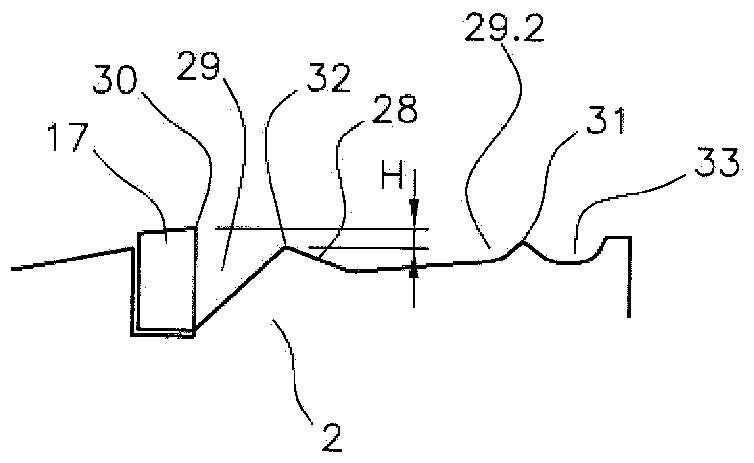

In a saw blade (1) having a saw blade body (2) and a plurality of regularly or irregularly distributed cutting teeth (3), the thickness of the saw blade body (2) is reduced in a tooth-bearing region (5) below the cutting teeth (3) compared to the rest of the saw blade body (2). The edges on the boundary sides can be provided with bevels to support improved discharge and directing of swarf.

Description

technical field The invention relates to a saw blade with a saw blade body and a plurality of cutting teeth distributed regularly or irregularly along the tooth-carrying region of the saw blade. Background technique Circular saw blades and band saw blades have basically been known for a long time. Saw blades are known with the most diverse cutting tooth shapes and cutting edges mounted on the teeth. Below the cutting teeth there is usually a chip space, through which the resulting chips are accommodated and carried away. Jamming of the saw blade should thus be prevented during operation. A problem with known saw blades is that the cutting teeth are not very resistant to bending and undesired noises are generated due to air turbulence. In addition, rough, grooved cutting surfaces are produced due to axial vibrations. Contents of the invention The object of the present invention is to provide a saw blade with improvements related thereto. According to the invention, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23D61/02

CPCB23D61/021B23D61/025Y10T83/9319B23D61/12B23D61/02B27B33/08B27B33/06

Inventor A.克内贝尔

Owner ALBERT KNEBEL HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com