Method and device for cleaning interiors of tanks and systems

A technology for cleaning devices and interior spaces, applied in boiler cleaning devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as unfavorable operation of equipment to be cleaned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

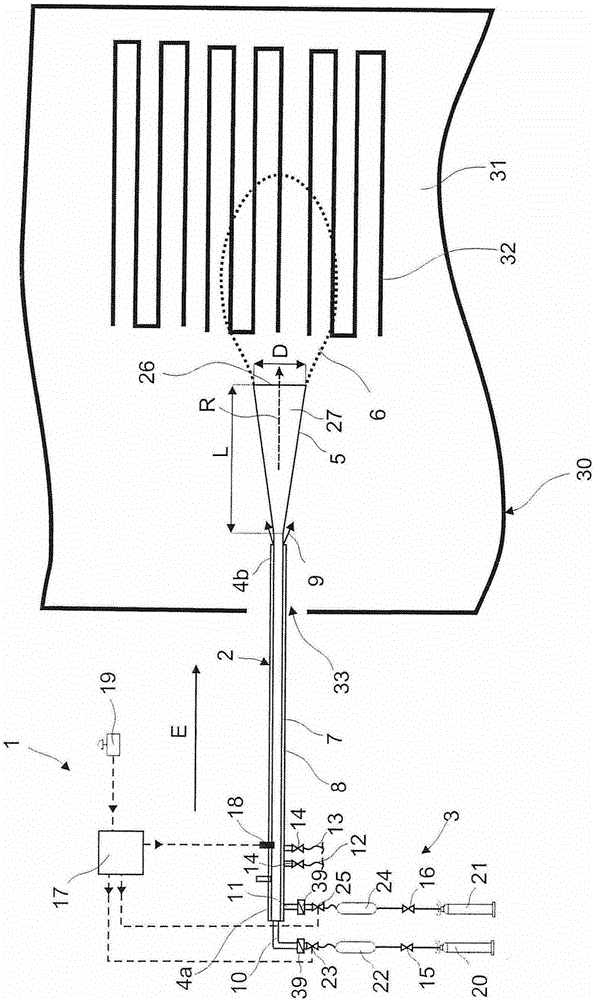

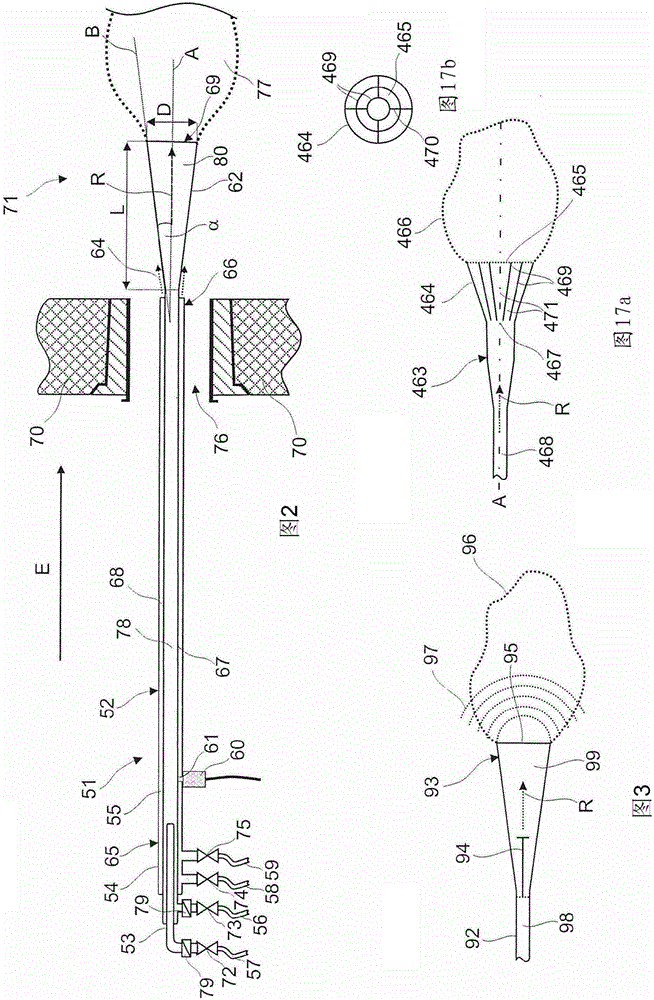

[0209] figure 1 A first exemplary embodiment of a cleaning device 1 according to the invention is shown, which is used to carry out the cleaning method according to the invention. Washing device 1 includes a coolable washing lance 2 . The cleaning lance 2 comprises an outer casing 8 and an inner gas conduit 7 arranged inside the outer casing 8 and also forming a pressure supply line. The outer sleeve 8 surrounds the inner gas conduit 7, thereby forming an annular cooling channel. Furthermore, the inner gas conduit 7 forms a closed pressure supply line.

[0210] The cleaning lance 2 comprises in its supply-side end section 4 a a metering device with a connecting pipe for supplying the gaseous components forming the explosive gas mixture.

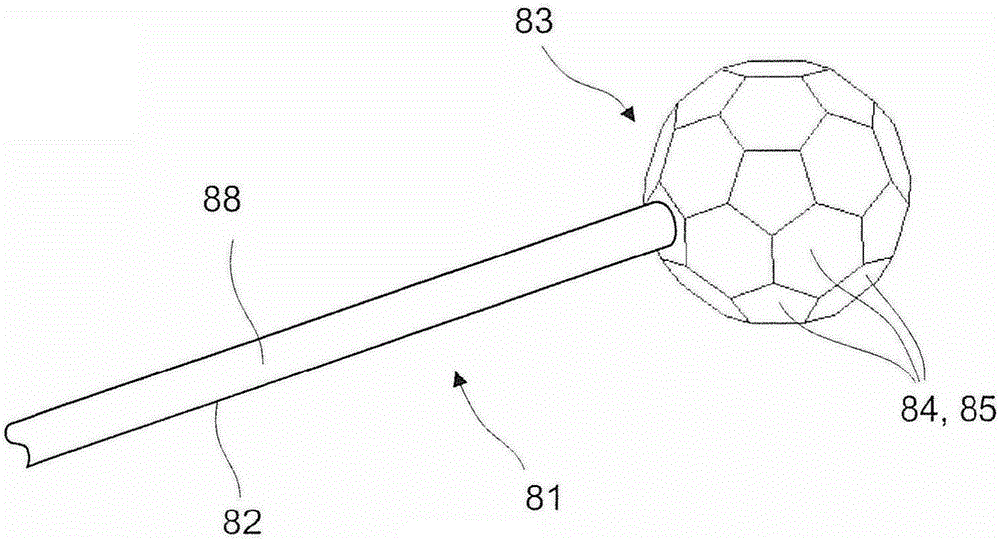

[0211] A discharge device formed in the shape of a funnel-shaped diffuser 5 is connected to the inner gas conduit 7 at the washing-side end section 4 b.

[0212] The cleaning lance 2 is supplied by the filling device 3 with gaseous compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com