Heat reclamation and temperature control for submersible vehicles that utilize fuel cells

A fuel cell and vehicle technology, applied in the direction of fuel cell engines, fuel cell heat exchange, fuel cells, etc., can solve the problem of reducing power and achieve the effect of enhancing power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The drawings and the following description illustrate specific exemplary embodiments. It will thus be appreciated that those skilled in the art will be able to devise various arrangements that embody the principles within the scope of and embody the embodiments, although not explicitly described or shown herein. Furthermore, any examples described herein are intended to aid in the understanding of the principles of the embodiments and are to be construed as not being limited to such specifically stated examples and conditions. Accordingly, the inventive concept is not limited to the specific embodiments or examples described below, but by the claims and their equivalents.

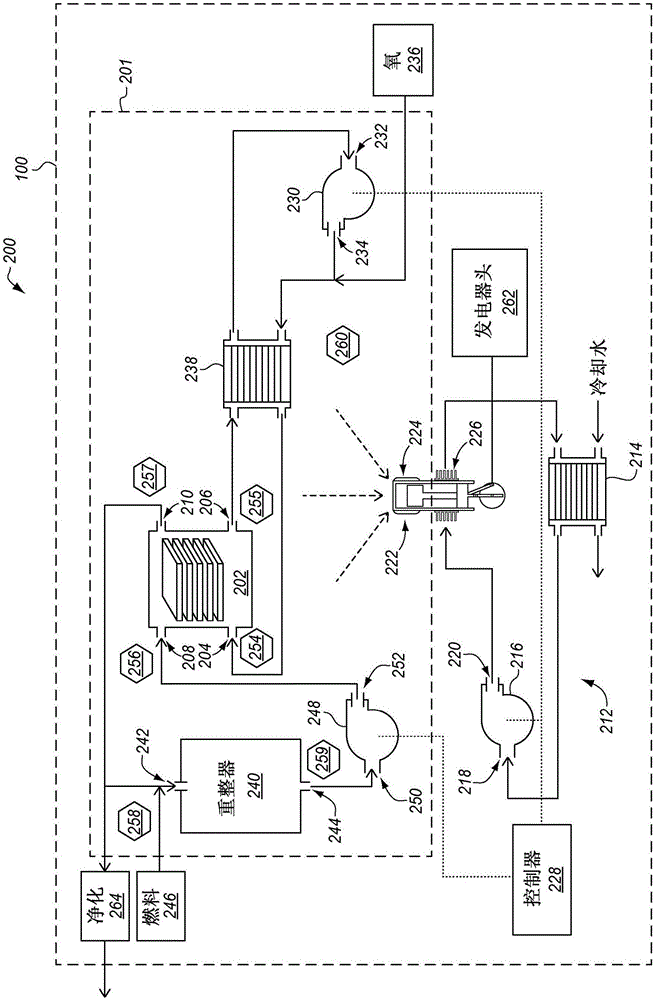

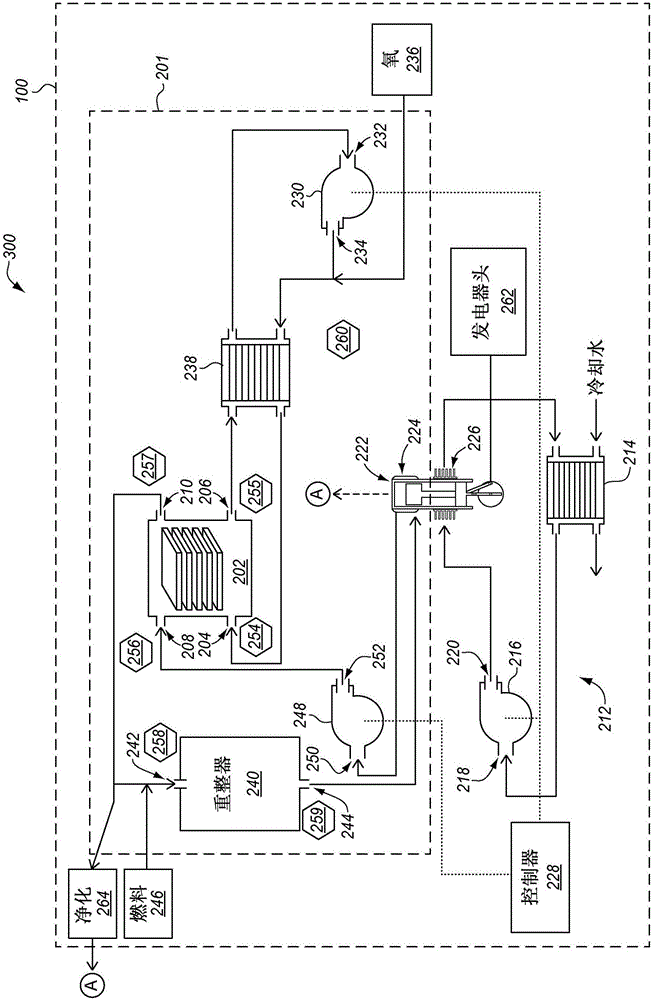

[0016] figure 1 An underwater vehicle 100 utilizing a Stirling engine for heat recovery and temperature control of an SOFC is shown in an exemplary embodiment. In this embodiment, vehicle 100 is described as an unmanned submersible vehicle (UUV), but in other embodiments, vehicle 100 may be any typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com