An automatic liquid level control system and control method for a ship model test pool

A technology for automatic liquid level control and test pool, applied in liquid level control, control/regulation system, non-electric variable control and other directions, can solve the problems of low liquid level control accuracy, low efficiency, inconvenience, etc. , good reliability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

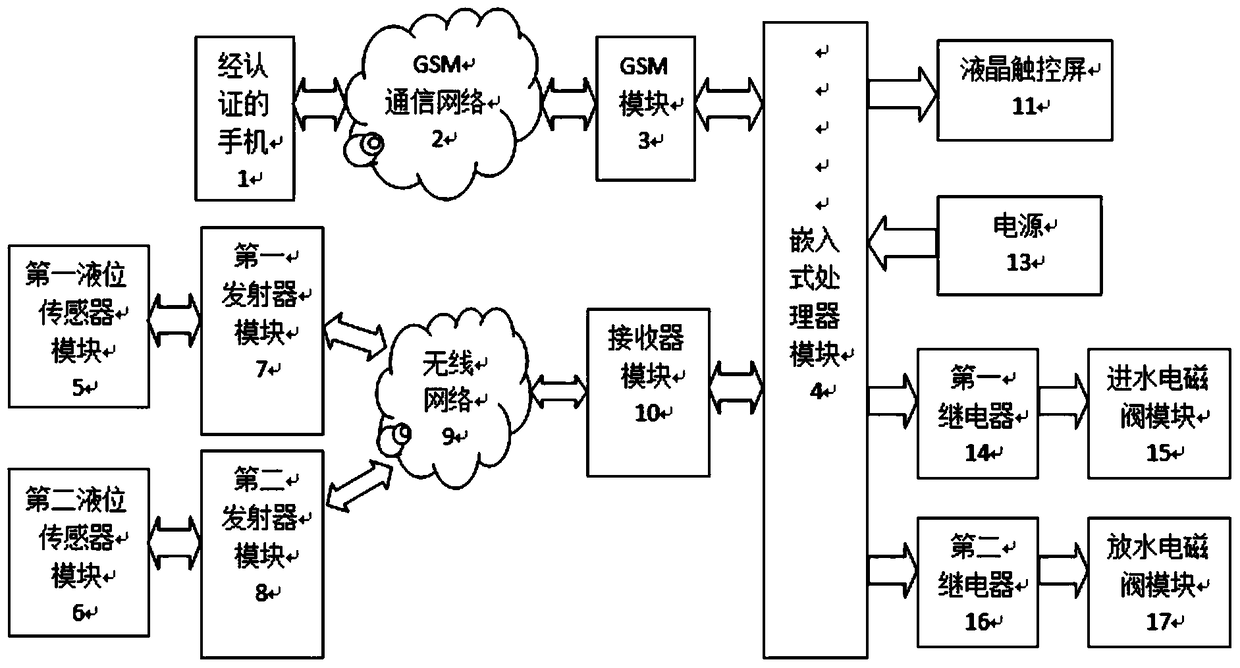

Method used

Image

Examples

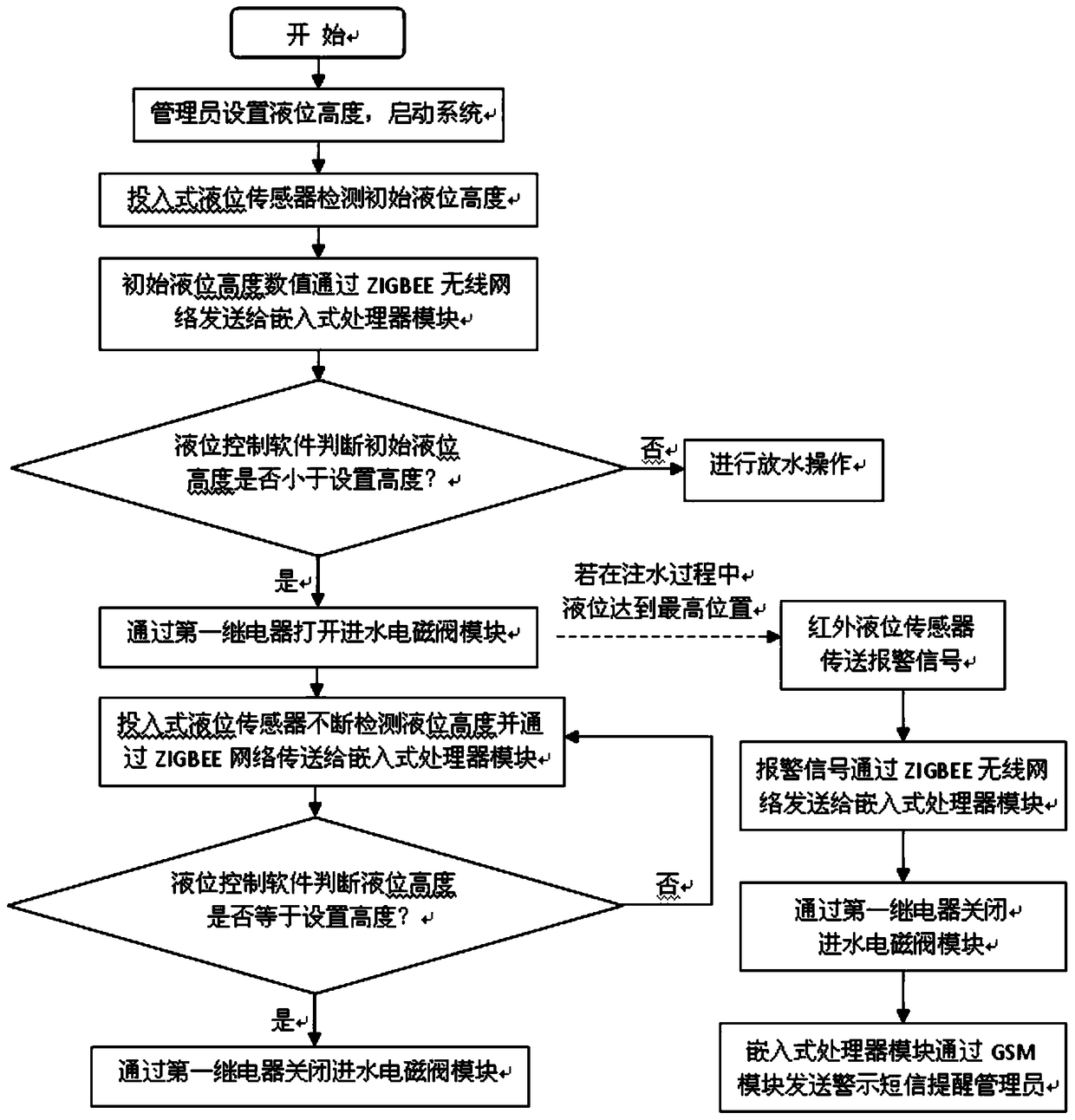

Embodiment 1

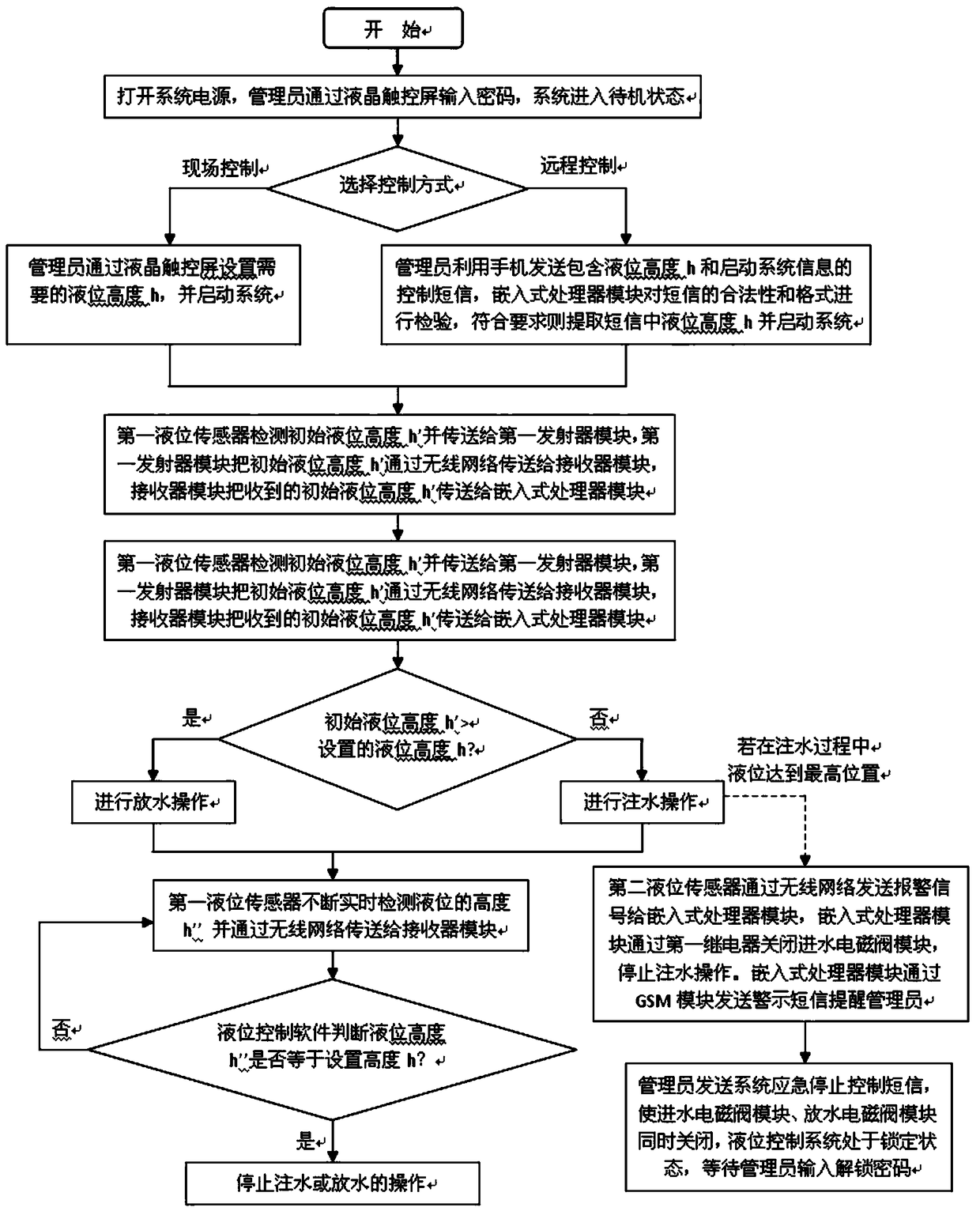

[0057] Embodiment 1: The water tank for the ship model test is empty or the liquid level has not reached the target height, and the water injection operation is performed. The flow chart of embodiment 1 is as Figure 2 to Figure 3 As shown, the specific implementation process is as follows:

[0058] The administrator sets the required liquid level height h through the liquid crystal touch screen 11, and starts the system.

[0059] The input liquid level sensor module 5 detects the initial liquid level height h', and transmits h' to the first ZIGBEE router module 7 through the RS485 interface, and the first ZIGBEE router module 7 then transmits the received initial liquid level height h' through the ZIGBEE The network 9 transmits to the ZIGBEE coordinator module 10 .

[0060] The ZIGBEE coordinator module 10 transmits the received initial liquid level height h' to the embedded processor module 4 through the USB interface, and the liquid level control software in the embedded ...

Embodiment 2

[0063] Embodiment 2: There is water in the ship model test pool or the liquid level exceeds the target height, and the water release operation is performed. The flow chart of embodiment 2 is as Figure 2 to Figure 4 As shown, the specific implementation process is as follows:

[0064] The administrator sets the required liquid level height value h through the liquid crystal touch screen 11, and starts the system.

[0065] The input liquid level sensor module 5 detects the initial liquid level height h', and transmits h' to the first ZIGBEE router module 7 through the RS485 interface, and the first ZIGBEE router module 7 then transmits the received initial liquid level height h' through the ZIGBEE The network 9 transmits to the ZIGBEE coordinator module 10 .

[0066] The ZIGBEE coordinator module 10 transmits the received initial liquid level height h' to the embedded processor module 4 through the USB interface, and the liquid level control software in the embedded processor...

Embodiment 3

[0068] Embodiment 3: remote operation control system for automatic liquid level control of ship model test pool. The flow chart of embodiment 3 is as Figure 5 As shown, the specific implementation process is as follows:

[0069] During the operation of the automatic liquid level control system of the ship model test pool, the administrator can use the authenticated mobile phone 1 to send control messages to the GSM module 3 through the GSM communication network 2, so as to achieve the purpose of remote control of the system.

[0070] When the administrator sends a control text message containing the liquid level value and start-up system information to the GSM module 3, the GSM module 3 transmits the content of the text message to the embedded processor module 4 through the serial port, and the embedded processor module 4 judges the received control message. The legality of SMS, if it is sent by an unauthenticated mobile phone, a warning message will be sent to remind the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com