Design method of dynamic optimization control layer output constraints of dilute acetone rectification industry

An output constraint, dynamic optimization technology, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of non-square uncertainty, difficulty in determining the output constraints of the dynamic optimization control layer, and few output constraint designs, etc. achieve the effect of ensuring the feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

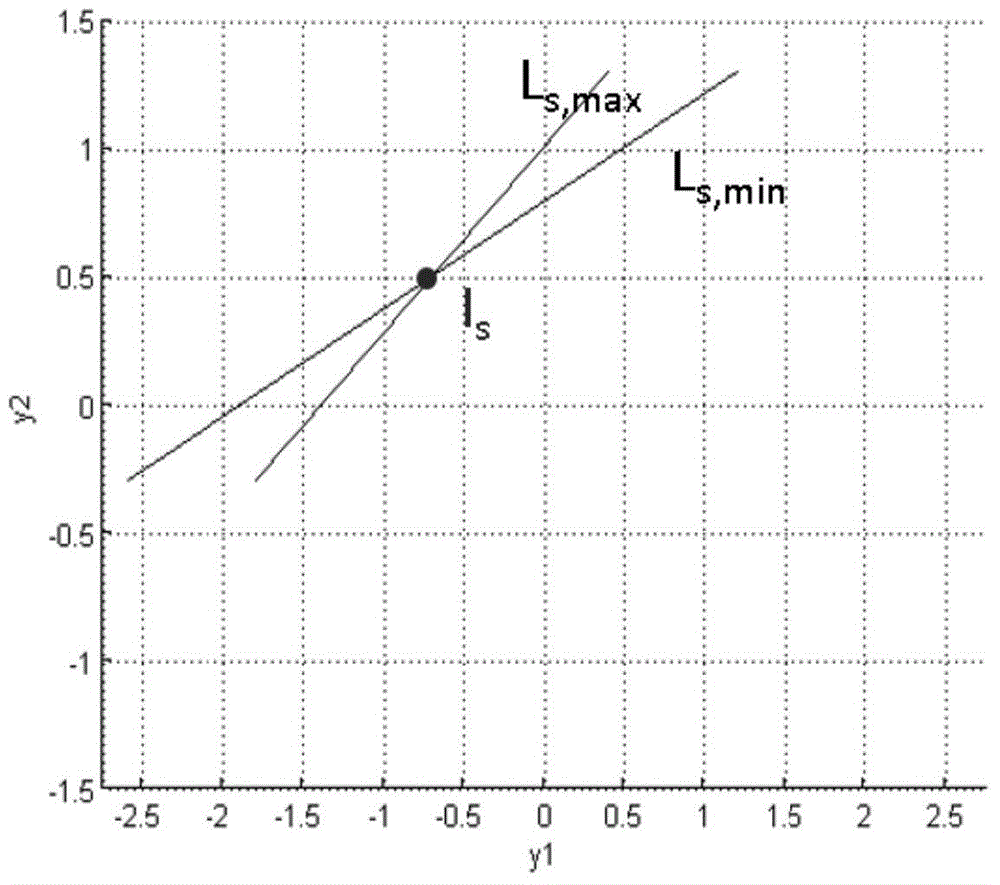

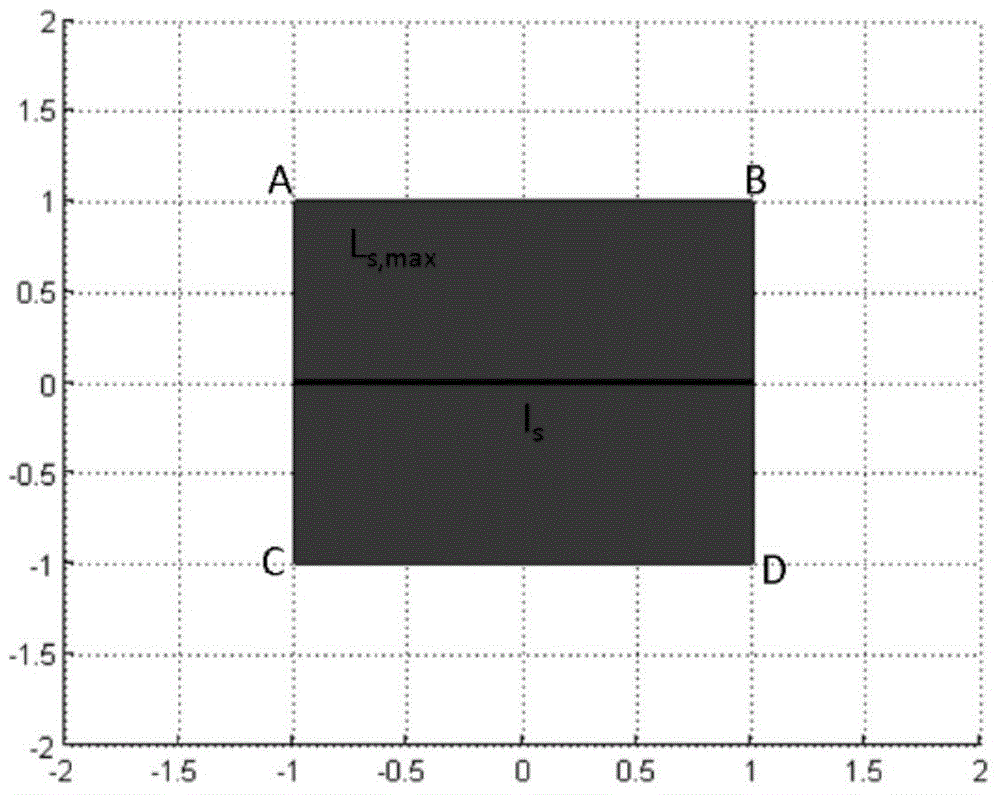

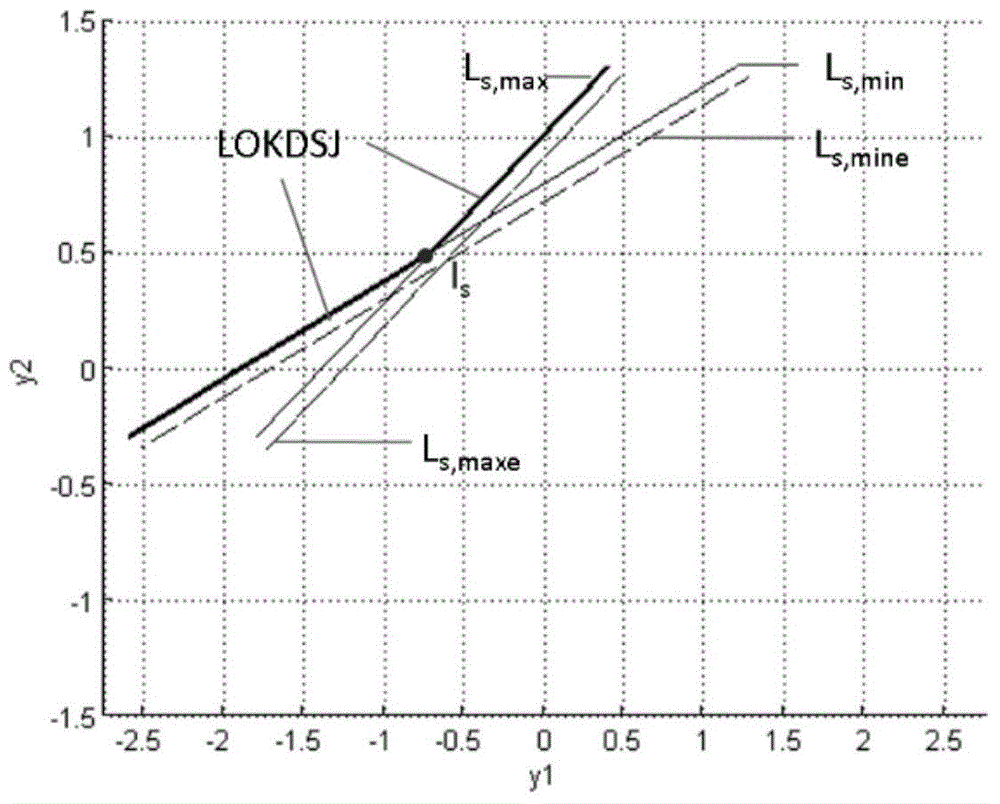

[0066] The following is a detailed description of the design method of the industry dynamic optimization control layer output constraints of the propylene ketone distillation industry in conjunction with the accompanying drawings.

[0067] A design method for the dynamic optimization control layer output constraints of the distilling industry of propylene glycol, including:

[0068] Step 1, aiming at the industrial model predictive control system for distilling propylene glycol with double-layer structure, obtain the gain model of the steady-state optimization layer of the model predictive controller.

[0069] The gain model is: y=Gu+G d d

[0070] In the formula: y is the n×1-dimensional system output, y∈SOC;

[0071] G is an n×m dimensional process gain matrix;

[0072] u is an m×1-dimensional system input variable, u∈SIC;

[0073] G d is an n×p-dimensional interference gain matrix;

[0074] d is the system disturbance variable of p×1 dimension, d∈DWC;

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com