Normal-temperature vacuum exhaust machining equipment of gravity heat pipe

A gravity heat pipe and processing equipment technology, applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of unfavorable energy saving, large consumption, uneven storage of medium in the product, etc., to ensure the quality of the product Pass rate, ensure rapid formation and maintenance, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

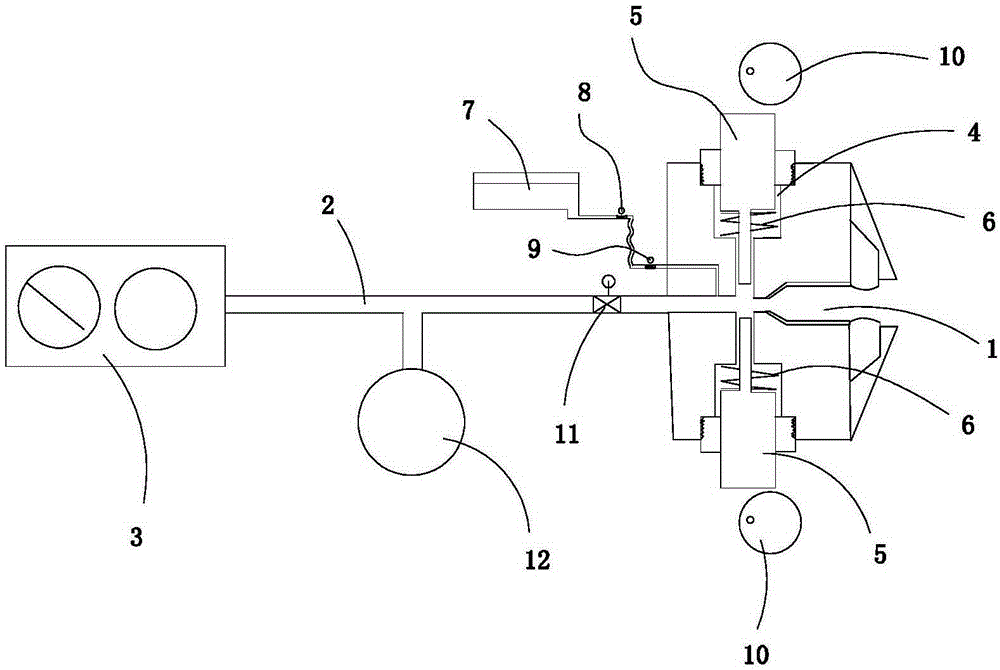

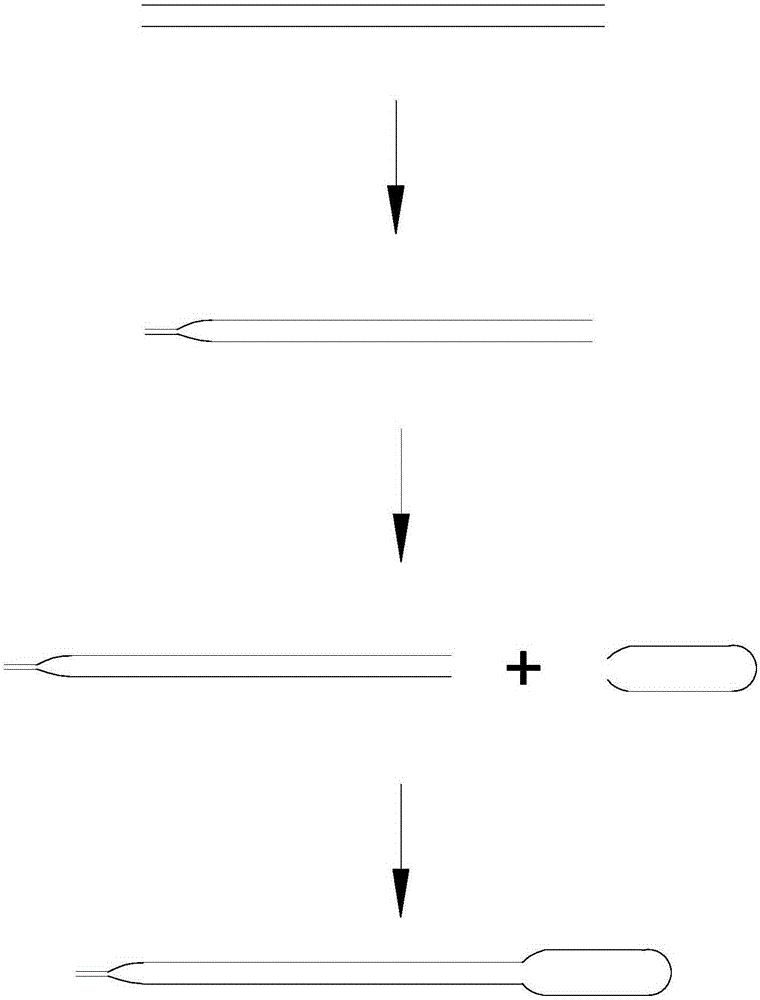

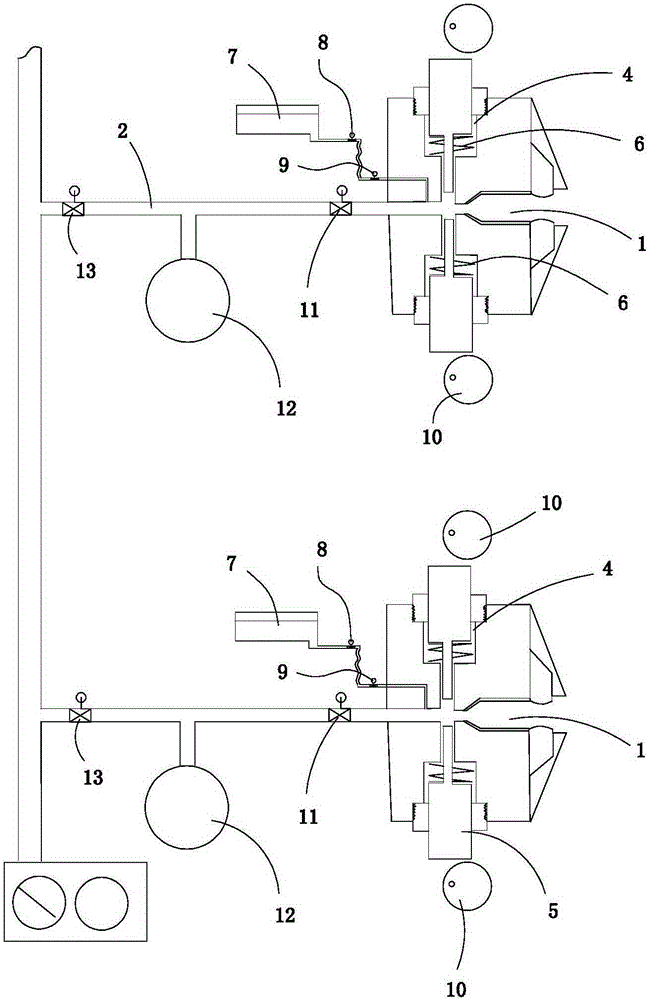

[0024] A kind of gravity heat pipe normal temperature exhaust vacuum processing equipment, such as figure 1 As shown, it includes a sealing interface 1, a quantitative delivery device and a pressure sealing device. The sealing interface 1 is connected to a vacuum pump 3 through an air suction line 2. The sealing interface 1 is suitable for connecting with a metal pipe (one end of which is open and the other end is open. closed, according to figure 2 The steps shown are to process metal tubes. The specific steps are as follows: the first step is to prepare a metal tube, usually a copper tube; the second step is to neck one end of the metal tube to form an open end; the third step is to weld a condensation head on the other end of the metal tube ), the opening end of the air pumping line 2 is provided with a first electromagnetic valve 11; It is connected at a position close to the sealing interface 1; the sealing pressure device is arranged adjacent to the sealing interface 1...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, except that the quantitative delivery device in this embodiment is a quantitative injector, which is used to control the amount of heat-conducting medium injected, with high precision and simplicity.

Embodiment 3

[0032] This embodiment is basically the same as Embodiment 1, the difference is that the number of the sealing interface 1 is two (in practice, it can also be set to more than two), and the air extraction pipeline 2 of each sealing interface 1 is provided with There is an air check valve 13, which can realize multi-station synchronous processing, and the air check valve 13 is set to prevent the air leakage of a single station from affecting other stations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com