Drying equipment for coir mat production

A technology for drying equipment and brown pads, applied in the field of drying equipment for brown pad production, can solve problems such as uneven heating of brown pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

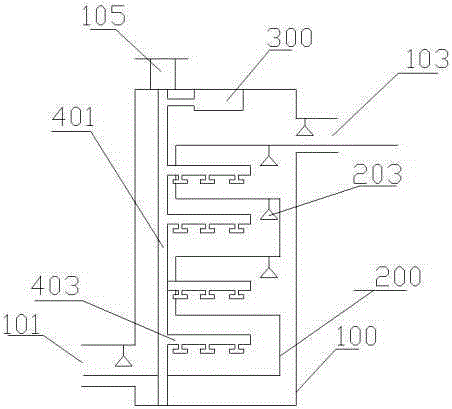

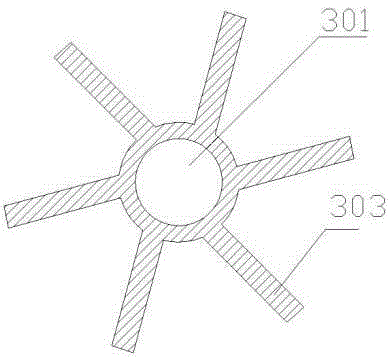

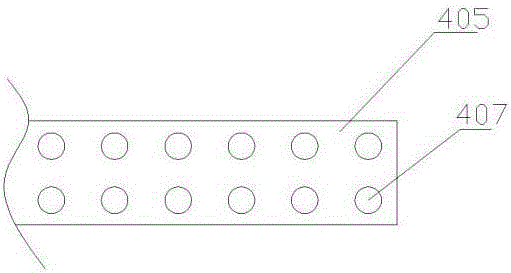

[0016] Such as figure 1 , figure 2 with image 3 The drying equipment shown for the production of palm mats includes a drying box 100. The drying box 100 is provided with an inlet 101, an outlet 103, a conveying mechanism 200, a glue nozzle 203, and a heating mechanism 300; The mechanism 200 is provided with a plurality of work surfaces, and rollers are arranged between the two connected work surfaces, and the rollers are fixed on the frame; the glue spray port 203 is arranged above the conveyor belt, and the heating mechanism 300 is arranged in the drying box 100 The upper end of the drying box 100 also includes an air supply mechanism. The air supply mechanism includes a main air duct 401. The main air duct is provided with a plurality of branch air ducts 403; the branch air duct 403 is connected with an air distribution plate 405 for air distribution. The plate 405 is provided with ventilation holes 407; the heating mechanism 300 includes a heat dissipation pipe 301 and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com