Hydraulic control system of high-speed performing hydraulic machine

A hydraulic control system and preforming technology, which is applied in the hydraulic field of hydraulic presses, can solve the problems of poor pressure stability and speed limitation of workpieces, and achieve the effects of eliminating impact, stably adjusting pressure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

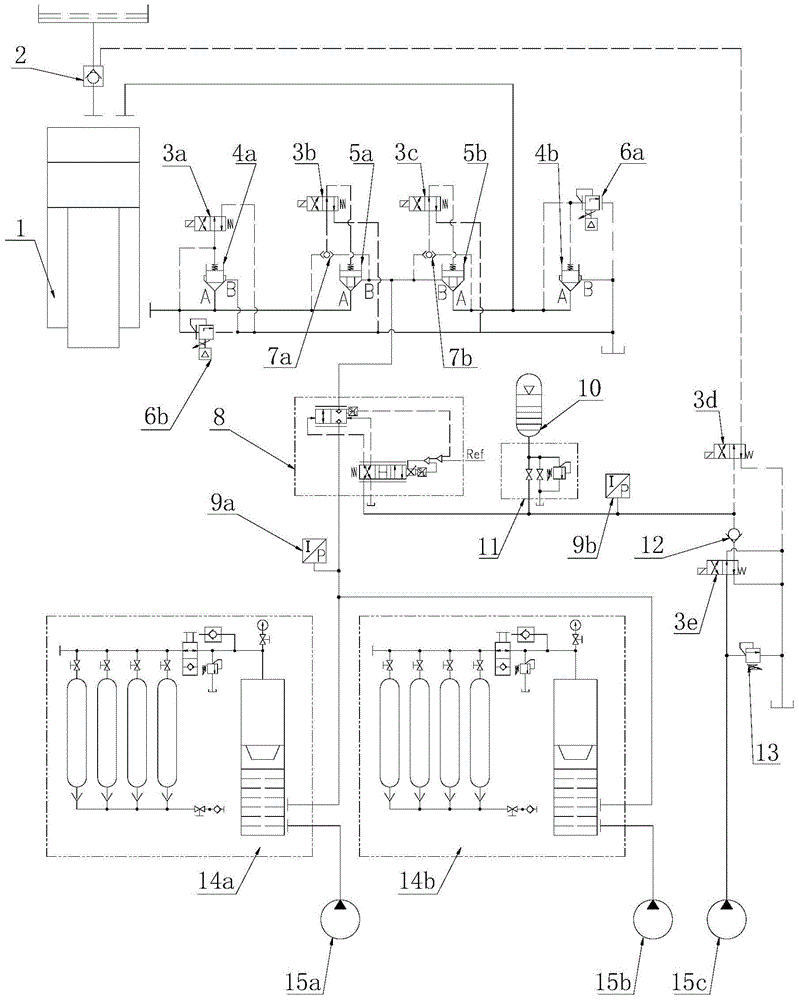

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0032] see figure 1 ,

[0033] A hydraulic control system for a high-speed preforming hydraulic press, including a power source circuit, a working cylinder oil supply circuit and a control oil circuit,

[0034] The power source circuit includes: the pump source A 15a, the pump source B 15b are connected to the oil inlet of the piston accumulator group A 14a, and the piston accumulator group B 14b; the pump source and the piston accumulator group are two groups , the two groups are connected to the proportional cartridge valve 8 after converging to provide oil source for the oil supply circuit of the working cylinder; a pressure sensor A 9a is set at the connection pipeline between the piston accumulator group 14 and the proportional cartridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com