Heat treatment method for vacuum high-pressure die-cast aluminum alloy casting

A heat treatment method and technology for aluminum alloys, applied in the field of heat treatment of high pressure die casting aluminum alloy die castings, can solve problems such as excessive residual level and no heat treatment allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

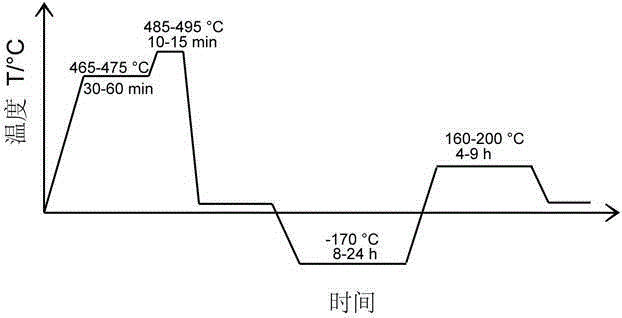

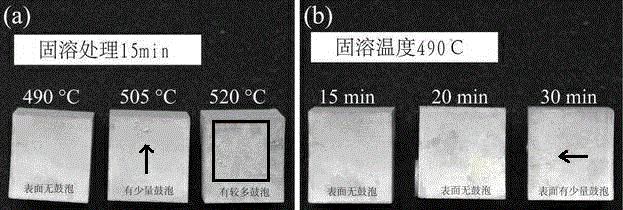

[0024] A high-performance aluminum alloy vacuum die-casting heat treatment process, comprising the following steps:

[0025] (1) The aluminum alloy high-pressure die casting is first raised to 465°C for solution treatment at a rate of 5°C / min for 60 minutes, then continues to rise to 495°C for solution treatment for 10 minutes, and then immediately put it into water (room temperature) for quenching;

[0026] (2) Place the quenched aluminum alloy high pressure die casting at room temperature for 9 hours;

[0027] (3) Then put the aluminum alloy high-pressure die casting into liquid nitrogen for cryogenic treatment for 12 hours, and the temperature of liquid nitrogen is -197°C;

[0028] (4) Aging the cryogenically treated aluminum alloy vacuum die-casting parts in an aging furnace with an aging temperature of 200°C and an aging time of 4 hours;

[0029] (5) Air cooling after aging;

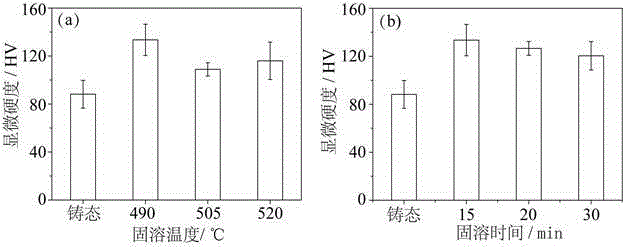

[0030] (6) The microhardness of the casting matrix is tested, which is 56% higher than that ...

Embodiment 2

[0032] A high-performance aluminum alloy vacuum die-casting heat treatment process, comprising the following steps:

[0033] (1) Heat the aluminum alloy high-pressure die casting to 470°C for 50 minutes at a rate of 8°C / min for solution treatment, then continue to rise to 490°C for 10 minutes and immediately put it into water (room temperature) for quenching;

[0034] (2) Place the quenched aluminum alloy high pressure die casting at room temperature for 10 hours;

[0035] (3) Then put the aluminum alloy high-pressure die casting into liquid nitrogen for cryogenic treatment for 14 hours, and the temperature of liquid nitrogen is -197°C;

[0036] (4) Aging the cryogenically treated aluminum alloy vacuum die-casting parts in an aging furnace with an aging temperature of 180°C and an aging time of 5 hours;

[0037] (5) Air cooling after aging;

[0038] (6) The microhardness of the casting matrix is tested, which is 62% higher than that of the unheated matrix (the average valu...

Embodiment 3

[0040] A high-performance aluminum alloy vacuum die-casting heat treatment process, comprising the following steps:

[0041] (1) Heat the aluminum alloy high-pressure die casting to 475°C for 30 minutes at a rate of 4°C / min, then continue to rise to 485°C for 15 minutes, and then put it into water (room temperature) for quenching;

[0042] (2) Place the quenched aluminum alloy high pressure die casting at room temperature for 6 hours;

[0043] (3) Then put the aluminum alloy high-pressure die casting into liquid nitrogen for cryogenic treatment for 16 hours;

[0044] (4) Aging the cryogenically treated aluminum alloy vacuum die-casting parts in an aging furnace with an aging temperature of 170°C and an aging time of 6 hours;

[0045] (5) Air cooling after aging;

[0046](6) The microhardness of the casting matrix is tested, which is 58% higher than that of the unheated matrix (the average value of 5 test points), and it is also significantly improved compared with ordinary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com