Device and method for adding alloy in non-vacuum induction furnace

A non-vacuum induction furnace and alloy technology, applied in furnaces, electric furnaces, furnace types, etc., can solve the problem that the molten steel cannot be completely isolated from air and molten steel, and achieve the effects of simple structure, improved quality and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] For further describing the present invention, below in conjunction with embodiment the present invention is described in more detail:

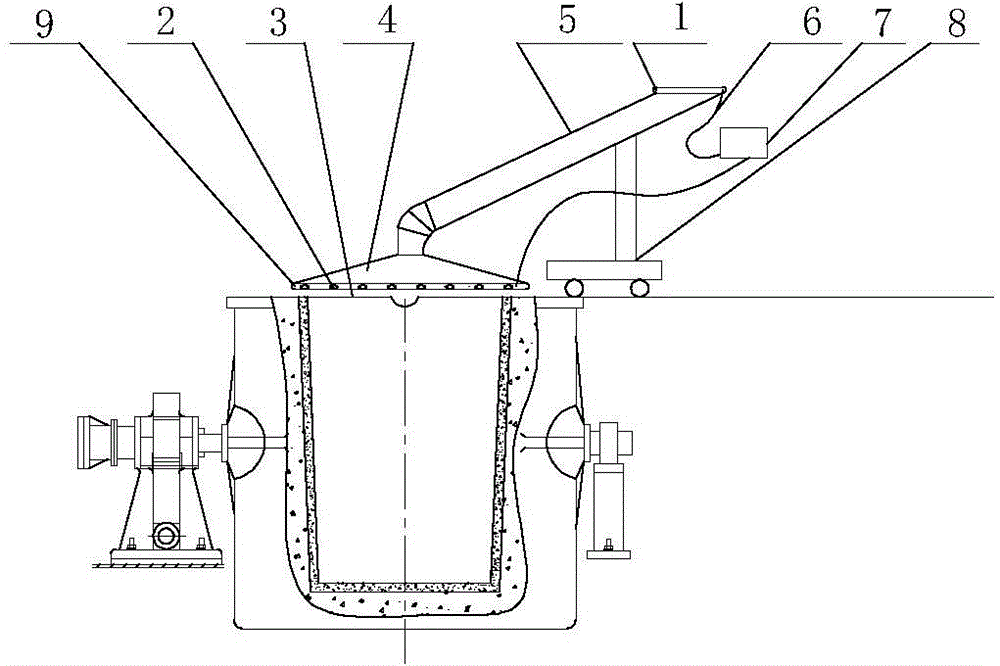

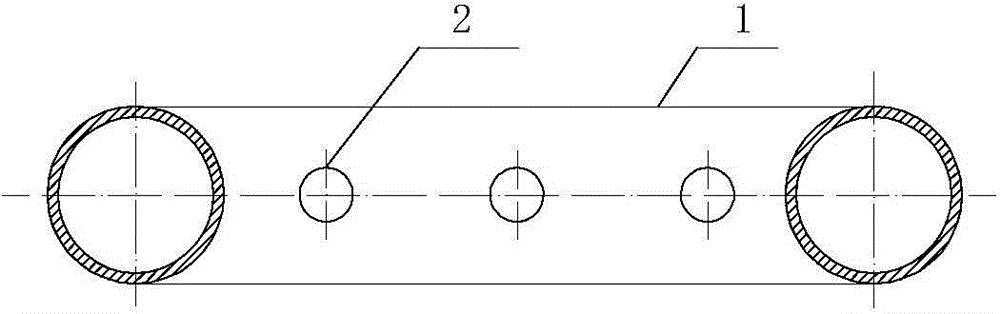

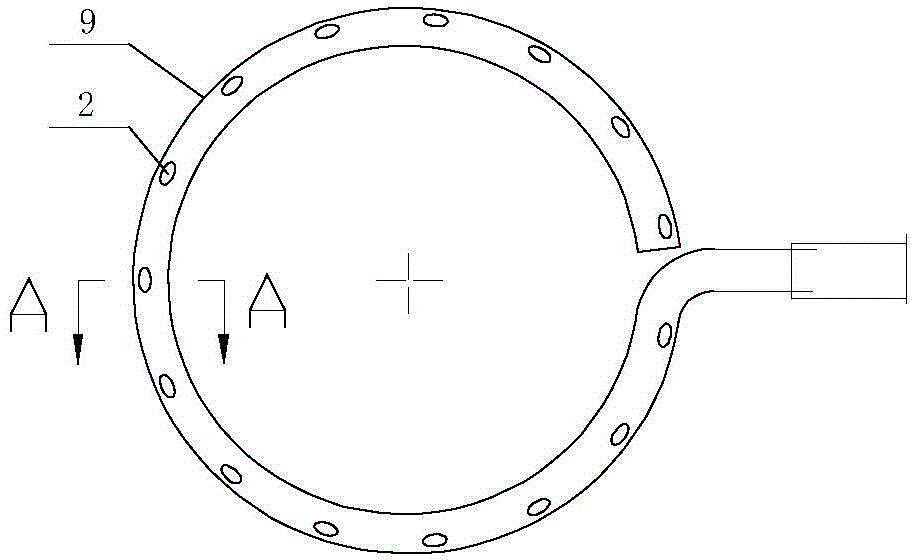

[0033] The non-vacuum induction furnace alloy adding device consists of an air blowing trolley 8, a splash guard 4, a conveying pipe 5, an upper air blowing pipe 1, a lower air blowing pipe 9, an air outlet 2, an air conveying pipe 6 and a protective gas source 7. The splash guard 4 and the conveying pipe 5 are connected by welding, and the splash guard 4 is in the shape of a hollow circular frustum or a prism. The splash guard 4 is located below the conveying pipe 5 , and the splash shield 4 and the conveying pipe 5 are welded on the blowing trolley 8 . The diameter of the splash guard 4 is designed according to the size of the furnace mouth, and the height of the splash guard 4 will help reduce the alloy drop, thereby reducing splashing. The upper air blowing pipe 1 and the lower air blowing pipe 9 are all made of circular rings by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com