Method of producing vanillin by transforming isoeugenol via Saccharomyces cerevisiae

A technology for isoeugenol and yeast, which is applied in the field of yeast transforming isoeugenol to produce vanillin, can solve the problems such as no yeast disclosure and report, and achieve the effect of satisfying the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

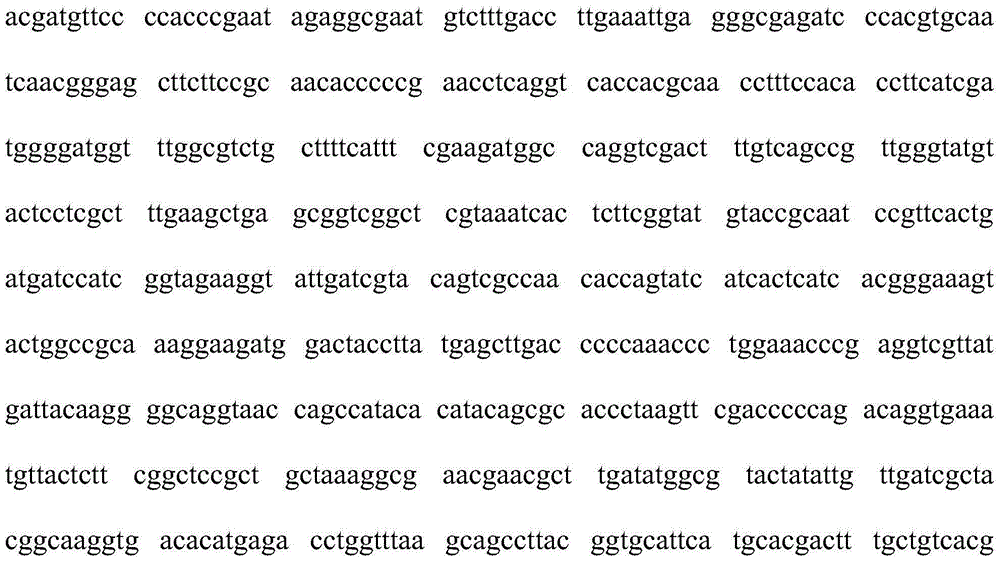

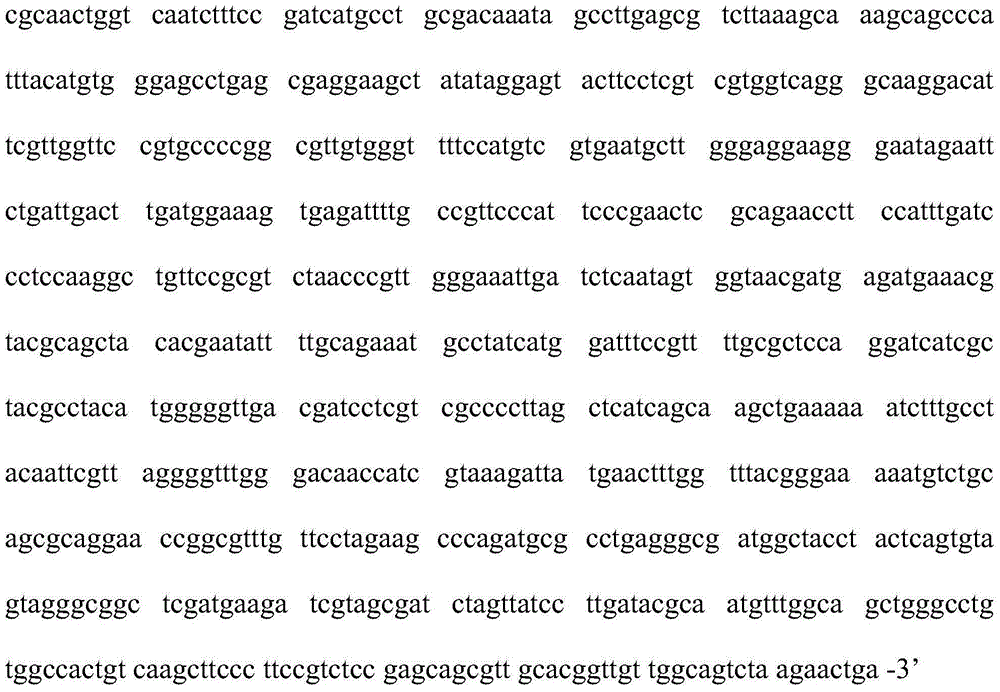

Image

Examples

preparation example Construction

[0059] 2. Preparation of culture medium

[0060] Raw material preparation:

[0061] 10*YNB (13.4% yeast nitrogen source base medium, containing ammonium sulfate without amino acid): Dissolve 134g of YNB containing ammonium sulfate in 1000ml of water, heat the solution to completely dissolve YNB in water, filter and sterilize at 4°C Store in the refrigerator.

[0062] 500*B (0.02% biotin): Dissolve 20 mg of biotin in 100 ml of water, sterilize by filtration, and store in a refrigerator at 4°C.

[0063] 10*D (20% glucose): Dissolve 200g of D-glucose in 1000ml of water, and sterilize in an autoclave for 15 minutes or by filtration.

[0064] 10*M (5% methanol): Mix 5ml methanol with 95ml water, filter sterilize, and store in a refrigerator at 4°C.

[0065] 1. Preparation of YPD liquid medium (1 liter) (including: 1% yeast extract, 2% peptone, 2% glucose):

[0066] Dissolve 10 g of yeast extract and 20 g of peptone in 900 ml of water. (If it needs to be made into a slant or ...

Embodiment 1

[0078] In a 50mL Erlenmeyer flask, add 0.6g of isoeugenol, 10mL of fermentation broth, add 10mL of glycine / NaOH buffer solution with a pH of 10.4 and a glycine concentration of 200mM, cover the mouth with two layers of gauze, and incubate at 30°C and 200rpm The transformation was carried out by shaking on a shaking table for 48 hours, and the concentration of vanillin in the final reaction solution was determined to be 3.5 g / L.

Embodiment 2

[0080] In a 50mL Erlenmeyer flask, add 0.5g of isoeugenol, 10mL of fermentation broth, add 10mL of glycine / NaOH buffer solution with a pH of 10.4 and a glycine concentration of 200mM, cover the mouth with two layers of gauze, and incubate at 30°C and 200rpm The transformation was carried out by shaking on a shaking table for 48 hours, and the concentration of vanillin in the final reaction solution was determined to be 3.25 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com