A kind of manufacture method and catalyst of isomaltooligosaccharide

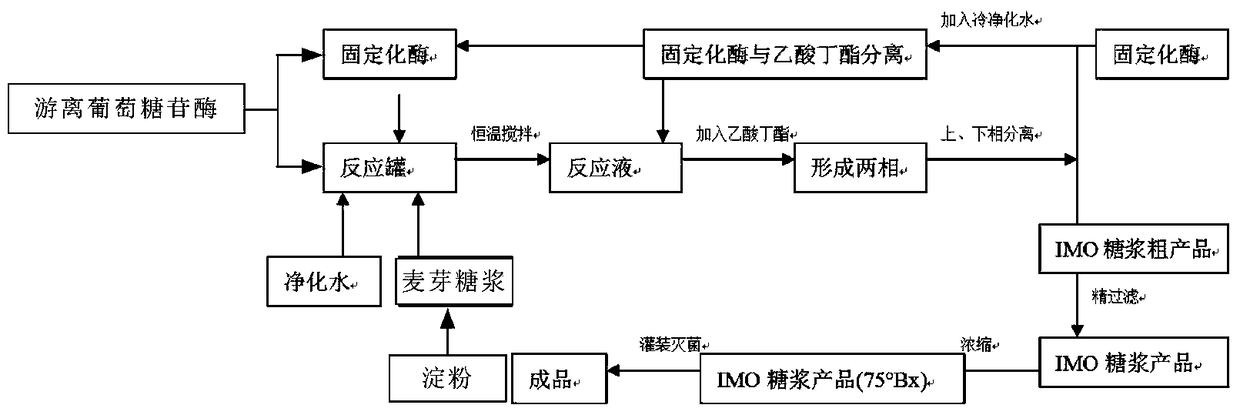

A technology for isomaltose oligosaccharide and maltose syrup, which is applied to the manufacture of isomalt oligosaccharides and the field of catalysts, can solve the problems of high operability, complicated equipment and the like, achieve high catalytic activity, low loss of enzyme amount, and improve catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Obtaining of α-glucosidase coding gene fragment

[0052] The mRNA of Aspergillus niger (Aspergillus niger) CBS 513.88 strain was extracted by liquid nitrogen grinding method, RT-PCR was performed with Oligo(dT) as primer under the action of reverse transcriptase, and cDNA was prepared by reverse transcription. Using this cDNA as a template, design upstream and downstream primers AGA-1 (SEQ ID NO: 3) and AGA- 2 (SEQ ID NO:4), AGB-1 (SEQ ID NO:5) and AGB-2 (SEQ ID NO:6), AGC-1 (SEQ ID NO:7) and AGC-2 (SEQ ID NO:8 ), AGD-1 (SEQ ID NO:9) and AGD-2 (SEQ ID NO:10), AGE-1 (SEQ ID NO:11) and AGE-2 (SEQ ID NO:12), AGF-1 (SEQ ID NO:12), AGF-1 (SEQ ID NO:10) ID NO:13) and AGF-2 (SEQ ID NO:14), and were amplified by PCR method to obtain agA of 1815bp, agB of 2892bp, agC of 2229bp, agD of 2958bp, agE of 1764bp and agE of 1968bp agF gene fragment.

Embodiment 2

[0053] Example 2: Construction of α-glucosidase single gene integrated expression vector

[0054] The gene fragment obtained in Example 1 was cloned into the SnaBI site of the pPIC9k plasmid to obtain recombinant plasmids pPIC9k-agA, pPIC9k-agB, pPIC9k-agC, pPIC9k-agD, pPIC9k-agE, and pPIC9k-agF.

Embodiment 3

[0055] Example 3: Construction of α-glucosidase double gene tandem integration expression vector

[0056] Using the recombinant plasmid in Example 2 as a template to design upstream and downstream universal primers AOX1 (SEQ ID NO: 15) and AOX2 (SEQ ID NO: 16), obtain the promoter sequence and α-glucosidase-related gene fragments of terminator sequences, AOX-agA, AOX-agB, AOX-agC, AOX-agD, AOX-agE, AOX-agF. And respectively cloned into the XbaI site of the corresponding plasmid in step 2 (the corresponding plasmid was digested by XbaI and pfu and other DNA polymerases were filled in, and the corresponding fragments were connected), to obtain the recombinant plasmid pPIC9k-agAB of tandem expression of α-glucosidase-related genes, pPIC9k-agAC, pPIC9k-agAD, pPIC9k-agAE, pPIC9k-agAF, pPIC9k-agBC, pPIC9k-agBD, pPIC9k-agBE, pPIC9k-agBF, pPIC9k-agCD, pPIC9k-agCE, pPIC9k-agCF, pPIC9k-agDE, pPIC9k- agDF, pPIC9k-agEF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com