Antibacterial polyvinyl chloride material, preparation method and application thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which can be used in surgery, medical science, etc., and can solve problems such as increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

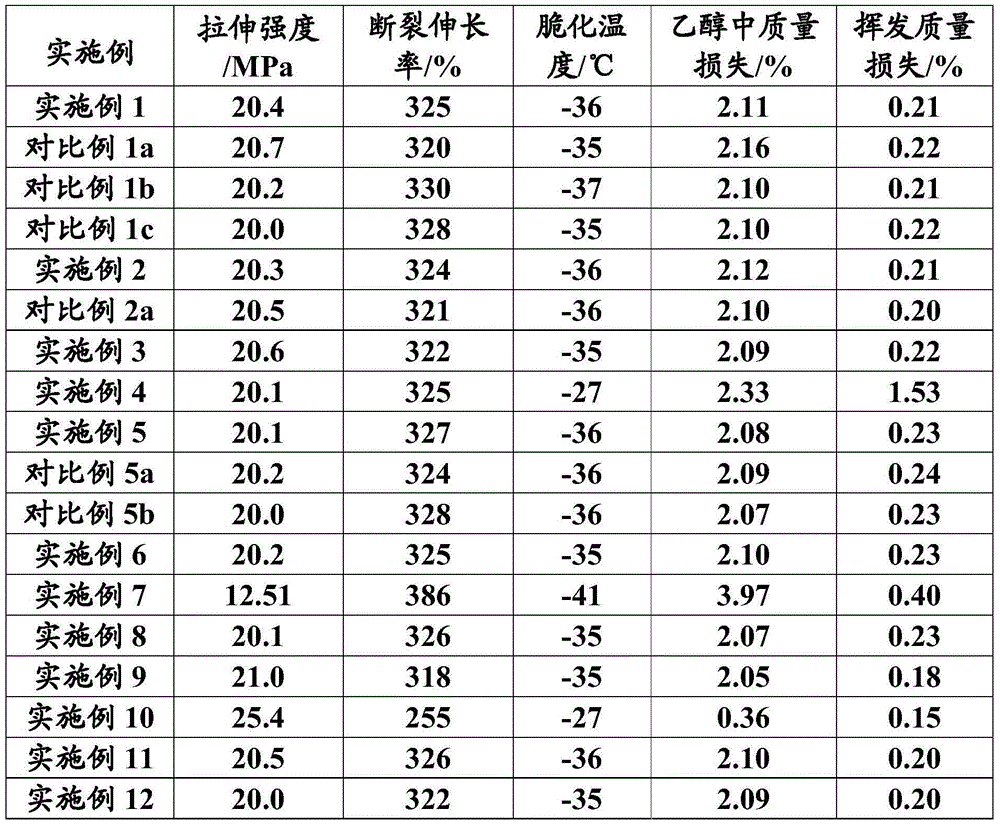

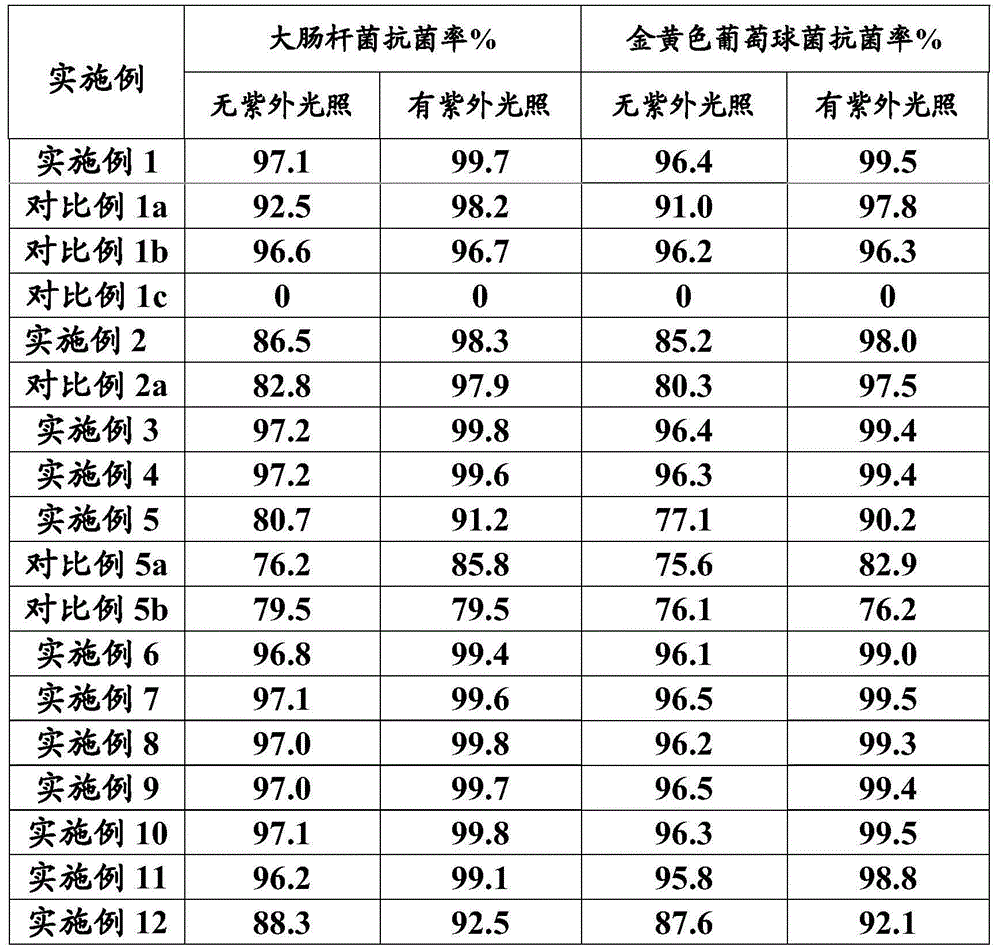

Examples

Embodiment 1

[0114] With 100 parts of PVC resin (weight-average molecular weight is 150,000, and M w / M n3.5, purchased from Formosa Plastics Industry (Ningbo) Co., Ltd., model is SG-4), 3 parts of nanometer silver-loaded titanium dioxide (average particle diameter is 30nm, silver content is 2% by weight, purchased from Xuancheng Jingrui New Material Co., Ltd. company, model VK-T07), 4 parts of polyquaternium-1 (purchased from Hubei Xinyuanshun Pharmaceutical Chemical Co., Ltd., pharmaceutical grade, relative molecular mass is 810.21), 4 parts of Chimassorb944 light stabilizer, 2 parts of calcium-zinc compound Stabilizer, 5 parts of epoxidized soybean oil, 0.4 part of tris(nonylphenyl phosphite) and 0.3 part of benzyl silicone oil are first added to the high-speed mixer, and the stirring is started at a temperature of 45°C, the blade speed is 950rpm, and the mixture is mixed for 5 minutes , and then add 45 parts of environmentally friendly and non-toxic composite plasticizers (including 2...

Embodiment 2

[0126] Repeat Example 1, the difference is: the nano-silver-loaded titanium dioxide used in Example 1 is replaced by nano-titanium dioxide (average particle size is 80nm).

[0127] The test results are shown in Table 1 and Table 2.

Embodiment 3

[0132] Repeat Example 1, the difference is: 4 parts of Chimassorb944 light stabilizer are replaced by 2 parts of CyasorbUV-3346 light stabilizer and 2 parts of Tinuvin622 light stabilizer.

[0133] The test results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com