A kind of polyamine cationic polymer modified starch flocculant and preparation method thereof

A technology of cationic polymers and ionic polymers, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as safety performance doubts, performance degradation, large feeding amount, etc., to reduce production costs, excellent flocculation effect, and improve flocculation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

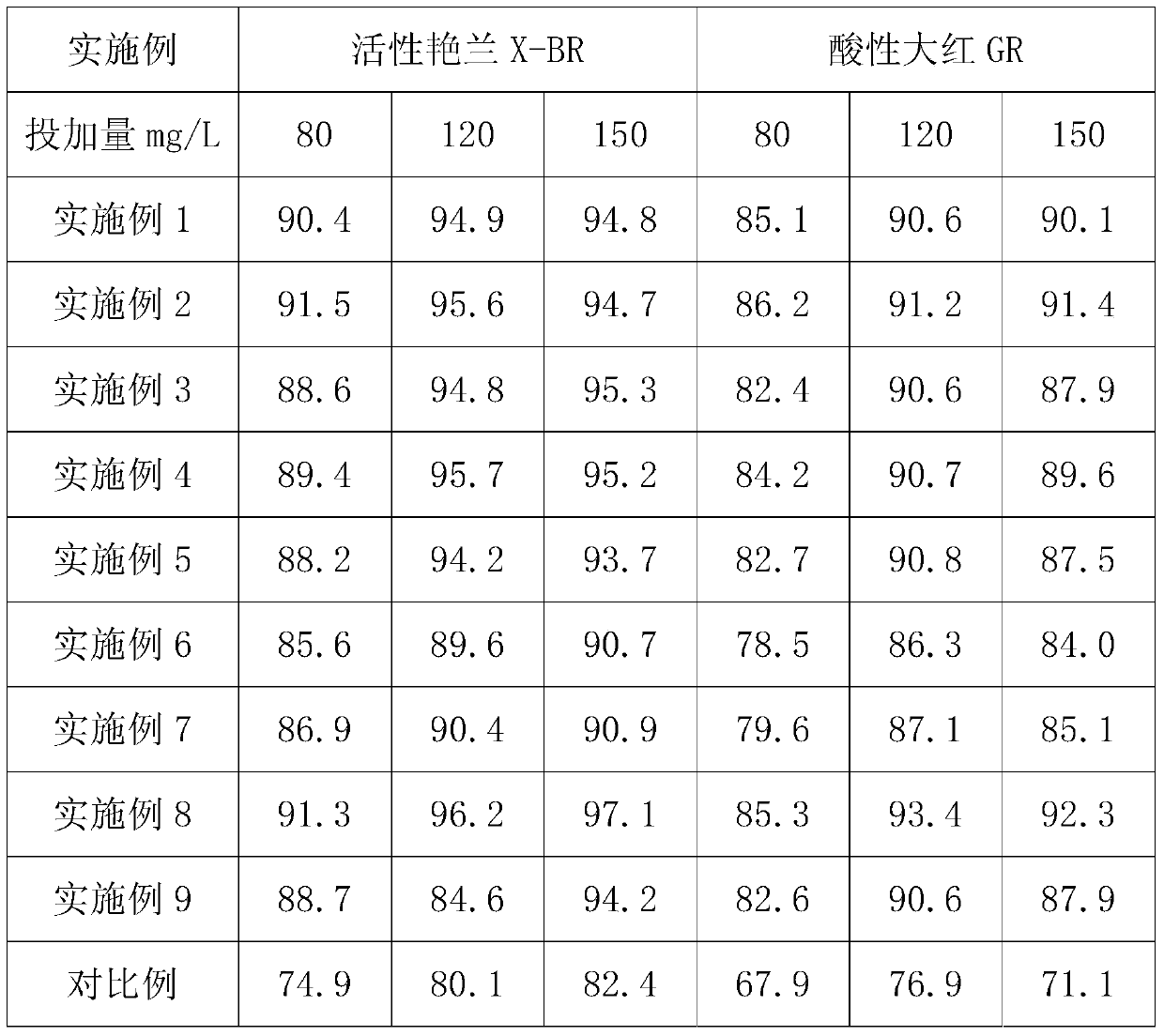

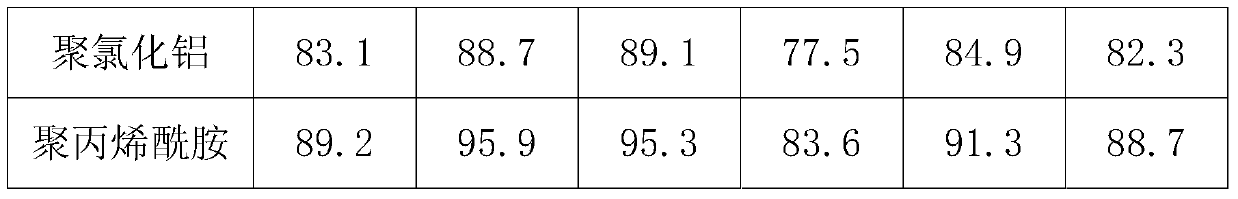

Examples

Embodiment 1

[0032] Below 30°C, slowly drop 15 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride into 10.3 parts of diethylenetriamine while stirring. Then the temperature was raised to 50° C., stirred at this temperature for 6 hours, cooled down to room temperature, and a cationized polymer was obtained.

[0033] Slowly add a mixture of 30 parts of cornstarch, 300 parts of water and 0.5 parts of 1-ethyl-2,3-dimethylimidazolium tetrafluoroborate to the above-mentioned cationized polymer while stirring at 50°C. The reaction was carried out for 8 hours, cooled to room temperature, and polyamine cationic polymer modified starch flocculant.

Embodiment 2

[0035] Below 30°C, slowly drop 19 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride into 10.3 parts of diethylenetriamine while stirring. Then, the temperature was kept at 30° C., stirred at this temperature for 6 hours, cooled down to room temperature, and a cationized polymer was obtained.

[0036] Slowly add a mixture of 30 parts of cornstarch, 300 parts of water and 0.5 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate to the above cationic polymer while stirring at 70°C, and react at this temperature for 8 Hours, cooled to room temperature, polyamine cationic polymer modified starch flocculant.

Embodiment 3

[0038] Below 30°C, slowly drop 23 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride into 10.3 parts of diethylenetriamine while stirring. Then the temperature was raised to 50° C., stirred at this temperature for 6 hours, cooled down to room temperature, and a cationized polymer was obtained.

[0039] Slowly add a mixture of 30 parts of cornstarch, 300 parts of water and 0.5 parts of 1-butyl-3-methylimidazolium tetrafluoroborate to the above cationic polymer while stirring at 90°C, and react at this temperature for 8 Hours, cooled to room temperature, polyamine cationic polymer modified starch flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com