Anti-swing and anti-collision control system and control method for lifting load of whirley crane

A control system and crane technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of no trajectory optimization control, lack of high efficiency, low work efficiency, etc., and achieve anti-swing and anti-collision reliability Strong, outstanding stability and high efficiency, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

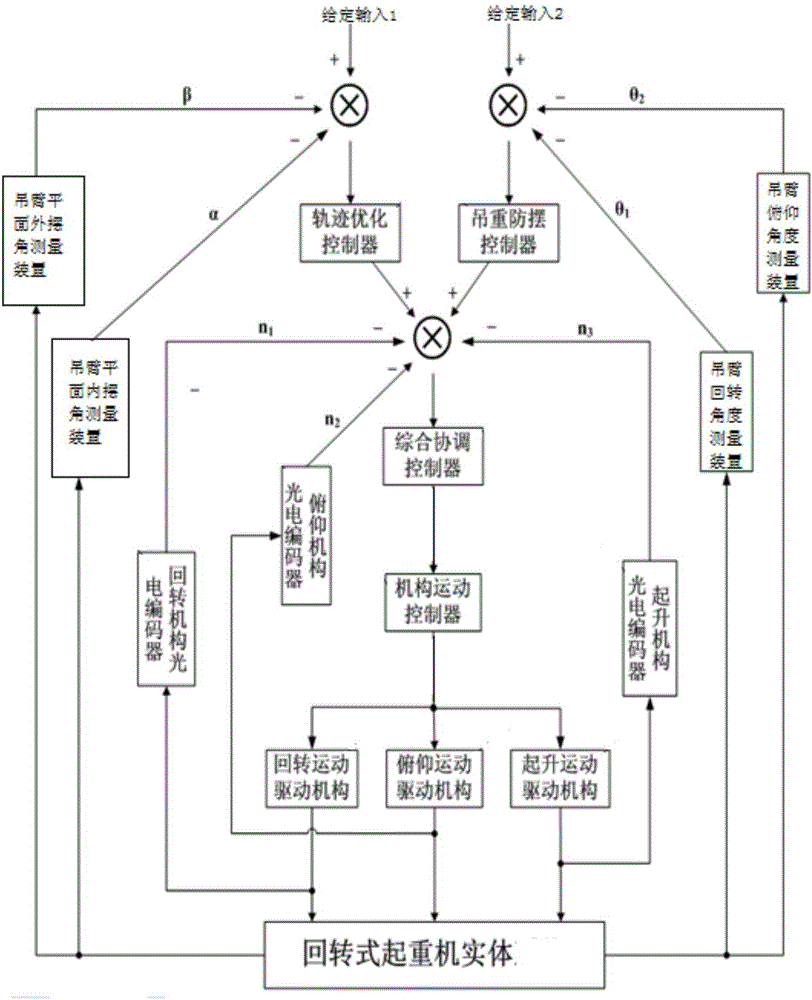

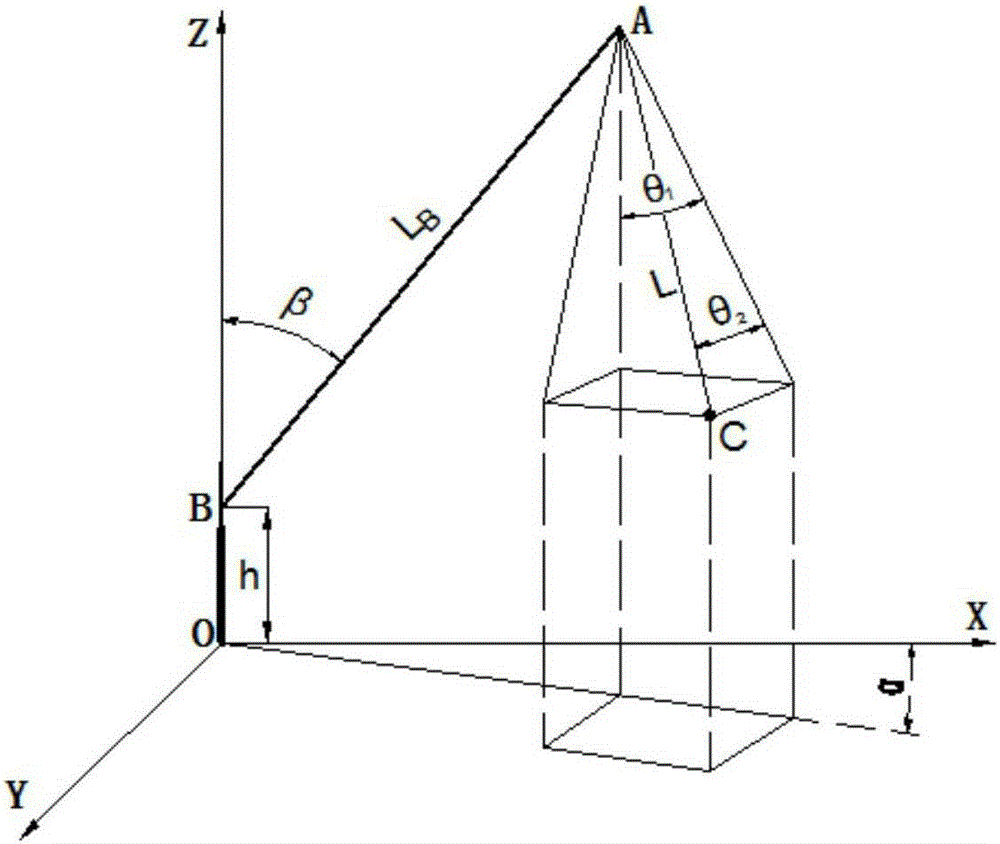

[0041] The present invention proposes a control system and control method for anti-swing and anti-collision hoisting of a rotary crane, which can simultaneously perform real-time feedback control on the trajectory of the hoisting weight during the operation of the rotary crane and the swing of the hoisting weight under the trajectory. The control system is mainly based on the hoisting control of the slewing crane, which combines trajectory optimization control and anti-swing control to form a safe, efficient and stable anti-swing and anti-collision comprehensive coordination control system; the control method of the system combines the three The organic combination of control modules, and the coordinated control module monitors the trajectory and swing of the hoisting weight in real time to ensure the safety, efficiency and stability of the crane operation process.

[0042] The invention integrates the coordinated control module, lifting control module, hoisting anti-swing cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com