A cloth cotton pendulum machine and its uniformity compensation method

A pendulum machine and uniformity technology, applied in the field of cloth cotton pendulum machine and its uniformity compensation, can solve the problem of uneven lateral density of mineral wool products, and achieve the effects of reducing processing cost, reducing internal stress and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

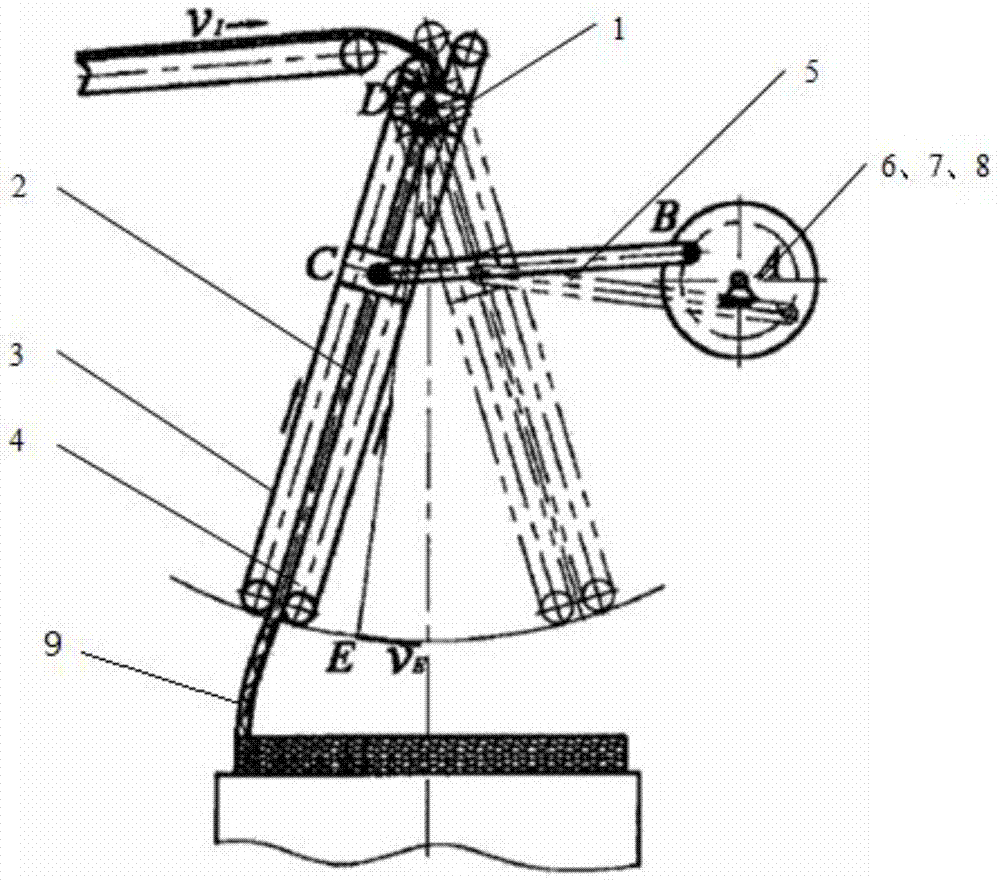

[0035] Such as figure 1 As shown, the existing cloth cotton pendulum machine includes a frame 1, a pendulum frame 2, a No. 1 belt conveyor 3, a No. 2 belt conveyor 4, a rocker arm 5, an eccentric wheel 6, a reducer 7 and a servo motor 8, etc. Servo motor 8, reducer 7, eccentric wheel 6, rocker arm 5 and pendulum frame 2 are connected sequentially, No. 1 belt conveyor 3 and No. 2 belt conveyor 4 are installed on pendulum frame 2 to form pendulum parts, pendulum Rack 2 is mounted on Rack 1;

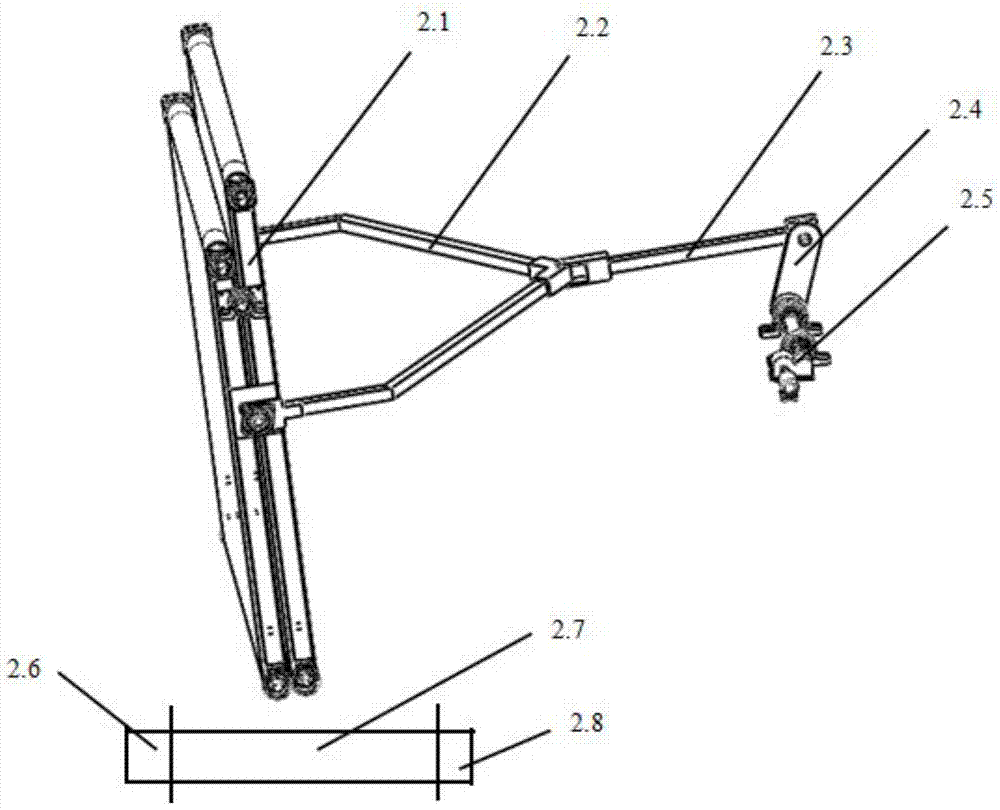

[0036] Such as figure 2 As shown, the cloth cotton pendulum machine of the present invention comprises a frame, a pendulum body 2.1, a rocker fork 2.2, a rocker lever 2.3, a crank 2.4 and a driving device 2.5; the driving device includes a servo motor and a reducer connected in sequence; the pendulum The body 2.1 is installed on the frame through the bearing structure, and can realize reciprocating swing; one end of the rocker fork is connected with the middle and upper part of the pendulu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com