Conveyor belt longitudinal tear detecting method based on metal film diffuse reflection

A metal film, longitudinal tearing technology, used in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as high hardware requirements, poor real-time performance, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

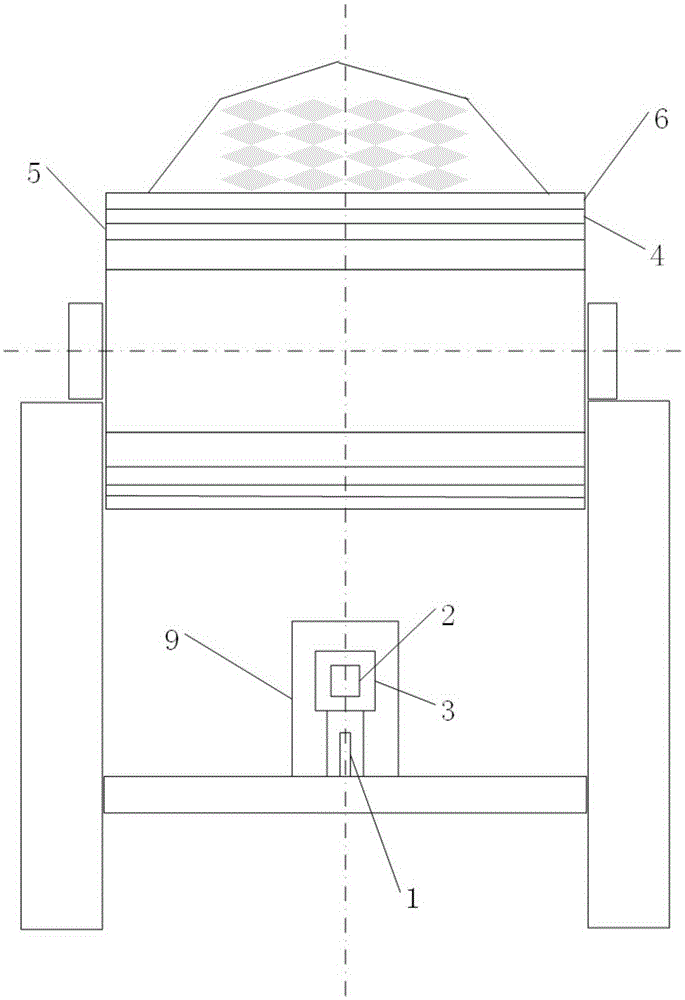

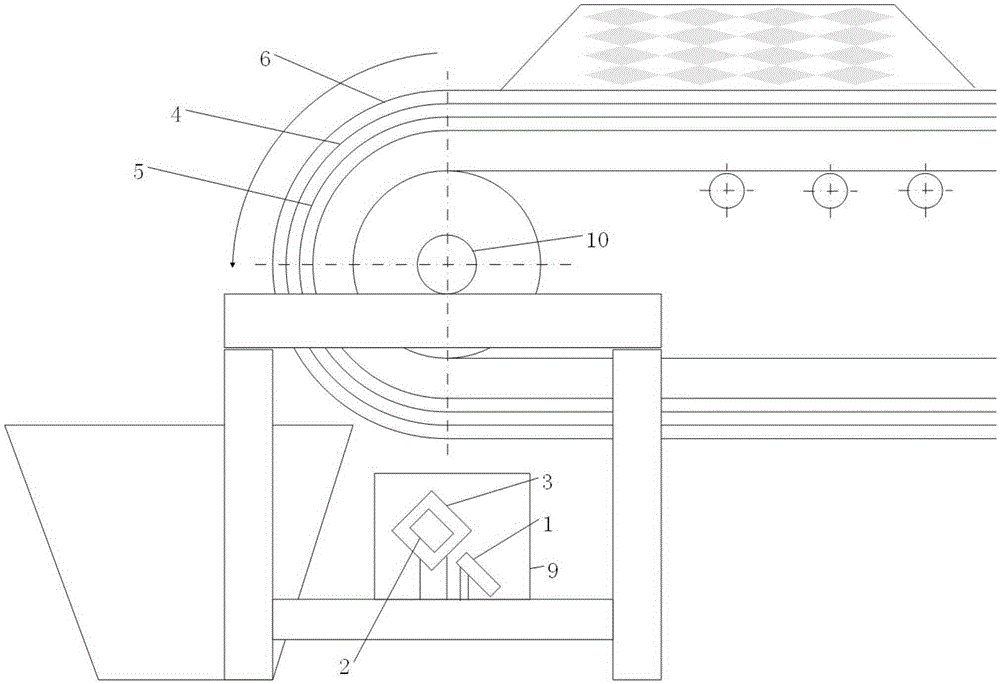

[0024] Below in conjunction with accompanying drawing, the implementation of the present invention is described in detail as follows:

[0025] 1. The working process of the above-mentioned new conveyor belt longitudinal tear detection method is as follows: the outer surface of the black tape is covered with tape glue 5, before the belt glue 5 is dried and cured, the frosted metal tin film 4 is affixed to the entire outer surface of the tape. After the film 4 is closely combined with the black tape, a layer of elastic transparent floor paint 6 is applied on the outer surface of the frosted metal tin film 4. The frosted metal tin film 4 has good flexibility and infrared reflection properties, and the elastic transparent floor paint 6 is It has high light transmittance and strong wear resistance. After the surface modification is completed, the tape not only maintains the original flexibility and wear resistance, but also the reflectivity of the outer surface for infrared rays is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com