Bean starch sheet cutting device with automatic cut-off function

An automatic cutting and cutting device technology, applied in metal processing, application, food preparation, etc., can solve the problems of uneven vermicelli, easily damaged vermicelli, uneven vermicelli length, etc., achieve good quality and taste, avoid vermicelli shrinkage, and benefit The effect of hanging dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0033] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

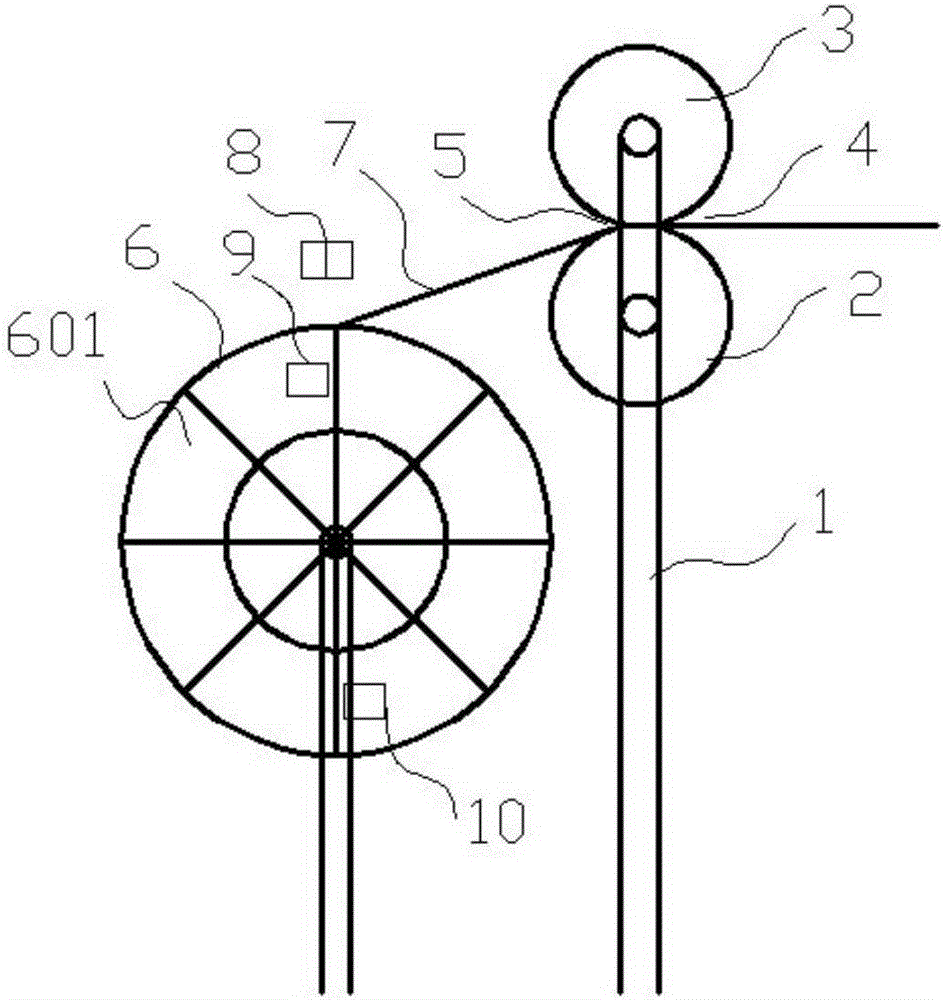

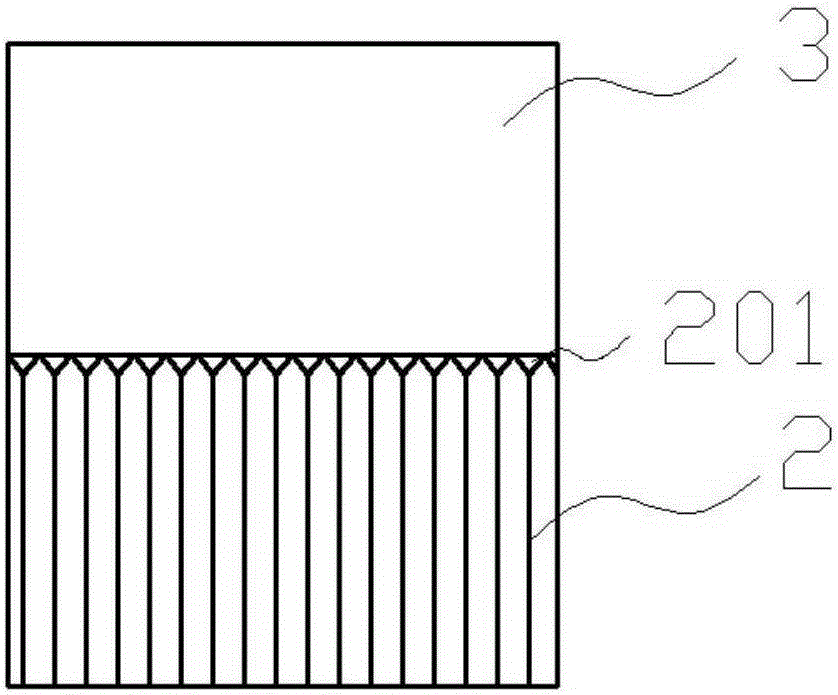

[0034] Such as figure 1 and figure 2 As shown, the steamed vermicelli is sent to the feed end 4 of the cutting piece by a conveyor belt or a delivery vehicle. The cutting piece is composed of two cylinders, the first cylinder 3 is arranged on the top, and the second cylinder 2 Set at the bottom, the surfaces of the two cylinders are tangentially fitted, which makes the jointed part form a squeeze belt, and the two cylinders are driven by the motor through gears or belts to rotate in reverse, from the input The vermicelli that enters from the material end 4 enters the extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com