Zinc oxide and gold nanoparticle composite material and preparation method thereof

A gold nanoparticle and composite material technology, applied in the field of functional material preparation, can solve problems such as high exciton binding energy, limited photocatalytic degradation of organic matter, large band gap, etc., achieve good application prospects, increase photoresponse range, and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1 Add 2.5mmol zinc nitrate, 3.75mmol tartaric acid and 2.5mmol potassium hydroxide to 50mL deionized water, stir well at room temperature to obtain a uniform milky white emulsion;

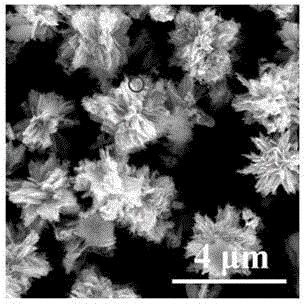

[0029] 1.2 Transfer the emulsion described in step 1.1 to the reactor, and hydrothermally heat it at 100°C for 6 hours. After the reaction, the precursor of zinc oxide is obtained by centrifugal washing and drying, and then the precursor is exposed to 300°C in an air atmosphere Calcined for 2h to obtain zinc oxide;

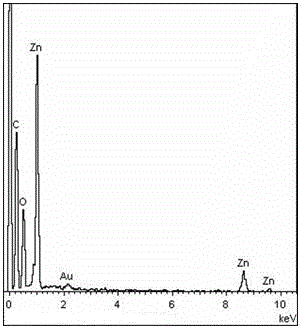

[0030] 1.3 Add the 0.2mmol zinc oxide prepared in step 1.2 to 20mL of deionized water, and after 6 hours of magnetic stirring, a uniform zinc oxide aqueous solution is obtained; then 50μL of concentration is 50mmolL -1 The gold chloroauric acid is added dropwise to the obtained zinc oxide solution, the solution of purple zinc oxide and gold nanoparticle composite material is obtained by stirring, and finally the zinc oxide and gold nanoparticle composite material is obtained by cent...

Embodiment 2

[0033] 2.1 Add 2.5mmol of zinc nitrate, 3.75mmol of tartaric acid and 2.5mmol of potassium hydroxide to 50mL of deionized water, fully stir at room temperature to obtain a uniform milky white emulsion;

[0034] 2.2 Transfer the emulsion described in step 2.1 to the reactor, and hydrothermally heat it at 150°C for 6 hours. After the reaction, the precursor of zinc oxide is obtained by centrifugal washing and drying, and then the precursor is exposed to 300°C in an air atmosphere Calcined for 2h to obtain zinc oxide;

[0035] 2.3 Add the 0.2mmol zinc oxide prepared in step 2.2 to 20mL of deionized water, and after 6 hours of magnetic stirring, a uniform zinc oxide aqueous solution is obtained; then the concentration of 50μL is 50mmolL -1 The gold chloroauric acid is added dropwise to the obtained zinc oxide solution, the solution of purple zinc oxide and gold nanoparticle composite material is obtained by stirring, and finally the zinc oxide and gold nanoparticle composite material is...

Embodiment 3

[0038] 3.1 Add 2.5mmol of zinc nitrate, 3.75mmol of tartaric acid and 2.5mmol of potassium hydroxide to 50mL of deionized water, fully stir at room temperature to obtain a uniform milky white emulsion;

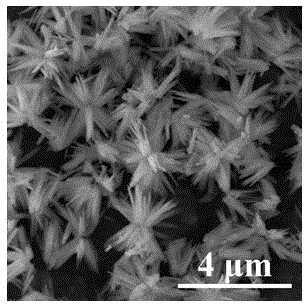

[0039] 3.2 Transfer the emulsion described in step 3.1 to the reactor, and hydrothermally heat it at 200°C for 3 hours. After the reaction, the precursor of zinc oxide is obtained by centrifugal washing and drying, and then the precursor is exposed to 300°C in an air atmosphere Calcined for 2h to obtain zinc oxide;

[0040] 3.3 Add the 0.2mmol zinc oxide prepared in step 3.2 to 20mL of deionized water, and after 6 hours of magnetic stirring, a uniform zinc oxide aqueous solution is obtained; then 50μL of concentration is 50mmolL -1 The gold chloroauric acid is added dropwise to the obtained zinc oxide solution, the solution of purple zinc oxide and gold nanoparticle composite material is obtained by stirring, and finally the zinc oxide and gold nanoparticle composite material is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com