A method for controlling the cooling water flow rate of twin-roll thin strip continuous casting rolls

A technology of cooling water flow rate and twin-roll thin strip, which is applied in the field of thin strip continuous casting technology, to achieve the effect of simple and reliable water supply system, rapid adjustment method, and ensure cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

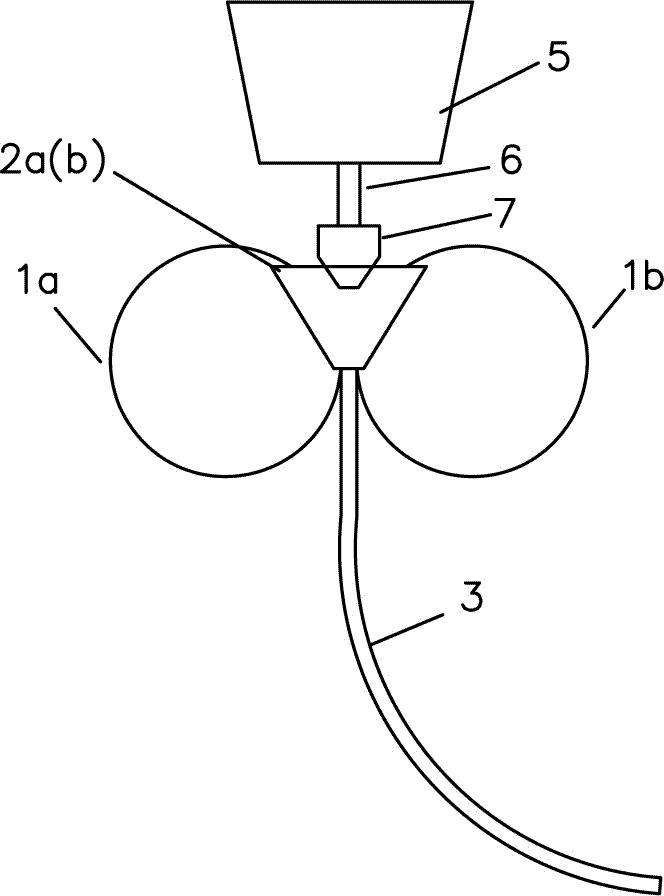

[0037] The twin-roll thin strip continuous casting process such as figure 1 As shown, the molten steel in the tundish 5 is evenly distributed through the nozzle 6 and the distributor 7 in the space surrounded by the two casting rolls 1a, 1b with cooling water inside and the ceramic plates 2a, 2b As the casting rolls rotate in opposite directions, the molten steel solidifies on the surface of the casting rolls and then forms a thin cast strip 3 at the smallest gap between the two casting rolls.

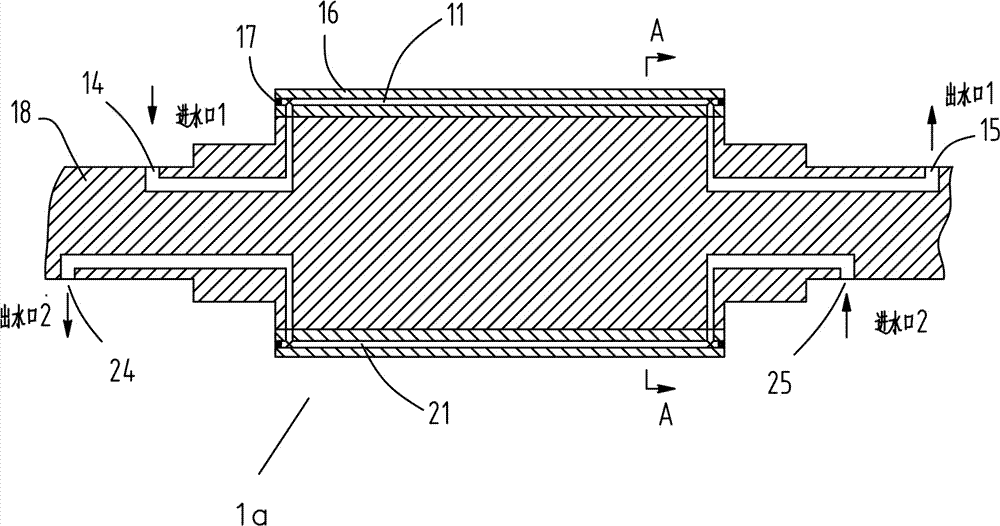

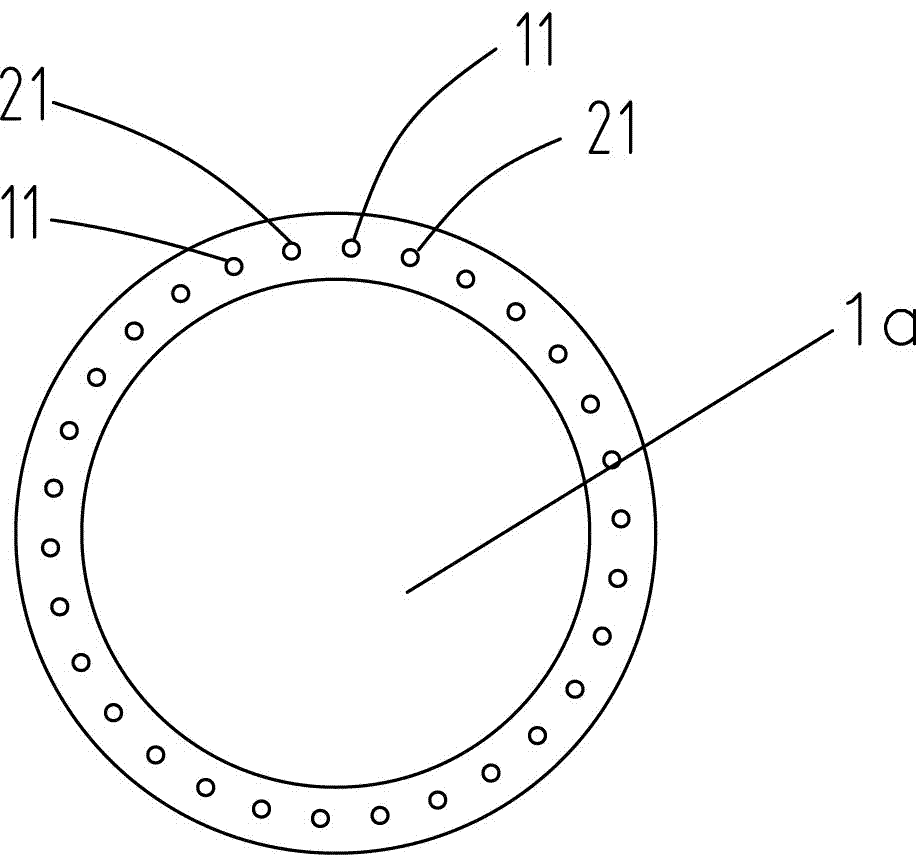

[0038] The structure of the cooling water channel inside the roll will be described in detail below in conjunction with the casting roll 1a.

[0039] Such as figure 2 , image 3 As shown, the casting roll includes a roll core 18 and a roll sleeve 16. Holes are processed on the roll core and the roll sleeve for cooling water to enter and exit, thereby forming two separate cooling water passages 1 and 2 inside.

[0040]Among them, the cooling water passage 1 includes a water inlet 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com