Semicontinuous casting device and method of aluminum alloy

A semi-continuous, aluminum alloy technology, applied in aluminum alloy semi-continuous casting devices and fields, can solve the problems of alloy plasticity stability and adverse effects on uniformity, and achieve the advantages of avoiding secondary pollution, refining solidification structure, and improving comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

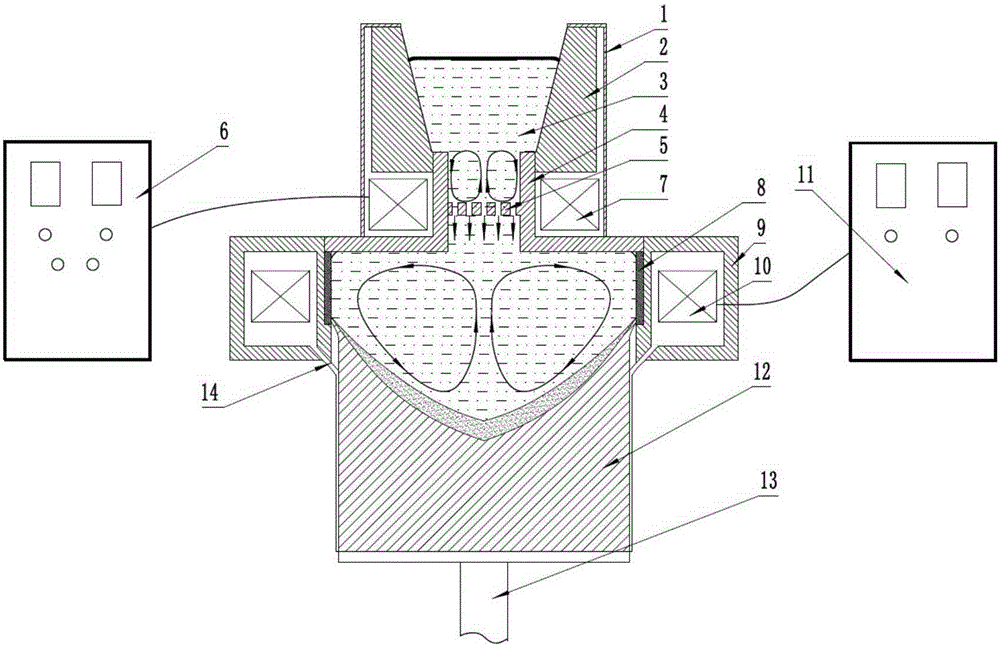

[0032] An aluminum alloy semi-continuous casting device, the schematic diagram is as figure 1 As shown, it consists of flow system, shear system, crystallization system, stirring system and traction system;

[0033] The flow supply system is composed of launder plate 1, launder 2 and guide tube 4; launder 2 is surrounded by launder plate 1, and guide tube 4 is located below launder 2;

[0034] The shearing system is composed of a diversion tube partition 5, an upper coil 7 and a variable frequency power supply 6; the upper coil 7 is located outside the draft tube 4, and the diversion tube partition 5 is located in the diversion tube 4, placed in a horizontal direction, and the diversion There are multiple through holes on the tube separator 5, the upper coil 7 is connected to the variable frequency power supply 6 through wires, and the shearing system applies alternating current to the upper coil 7 to make the aluminum melt 3 in the draft tube 4 generate a strong and rapid flo...

Embodiment 2

[0040] An aluminum alloy semi-continuous casting device, its structure is the same as that of Example 1, the difference is that: the diameter of the opening on the diversion tube separator is Φ5mm; the spacing between the holes on the diversion tube separator is 5mm; the upper coil and the lower coil are both It is wound from flat copper wire with 50 turns.

Embodiment 3

[0042] An aluminum alloy semi-continuous casting device, its structure is the same as that of Example 1, the difference is that: the diameter of the opening on the diversion tube partition is Φ30mm; the spacing between the holes on the draft tube partition is 50mm; the upper coil and the lower coil are both It is wound from flat copper wire with 200 turns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com