Single-row type disc piece pouring combination mold

A disc-shaped, single-row technology, which is used in casting molding equipment, molds, cores, etc., can solve the problems of long cooling time, low production efficiency, and inability to achieve mass production, and achieves reasonable structure, easy pouring, and design. clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

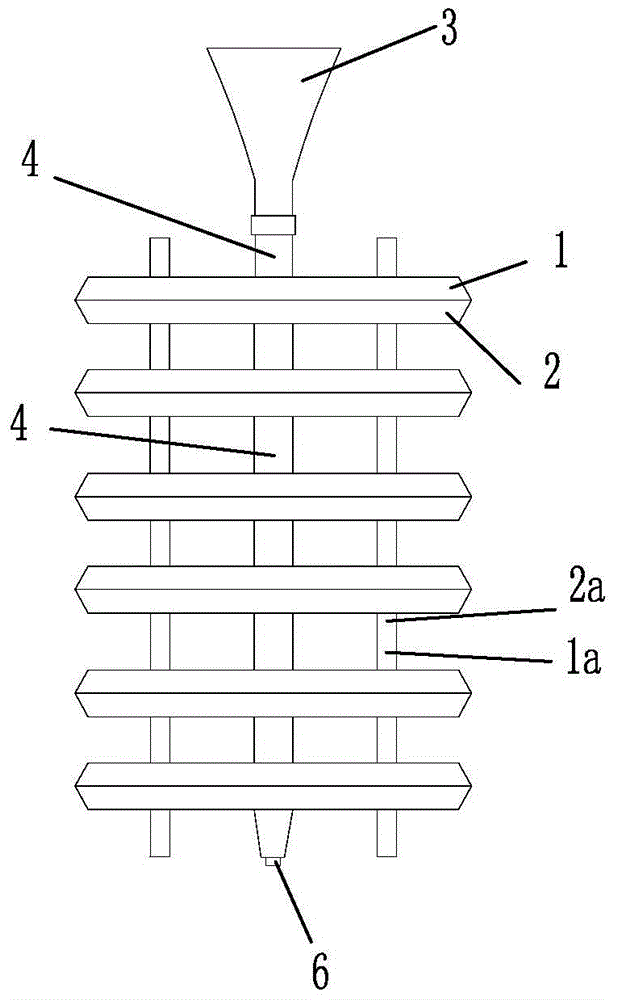

[0015] combine figure 1 — Figure 4 As shown, a single-row disc pouring combination mold is mainly composed of an upper sand shell 1, a lower sand shell 2 and a gate 3, all of which are made of coated sand on a core shooting machine. Using coated sand to make sand shells and gates on a core shooter is a traditional technology, and will not be repeated here. The core improvement is to optimize the structure of the upper sand shell 1, lower sand shell 2, and gate 3 to achieve one-time casting molding. The purpose of multiple disc pieces.

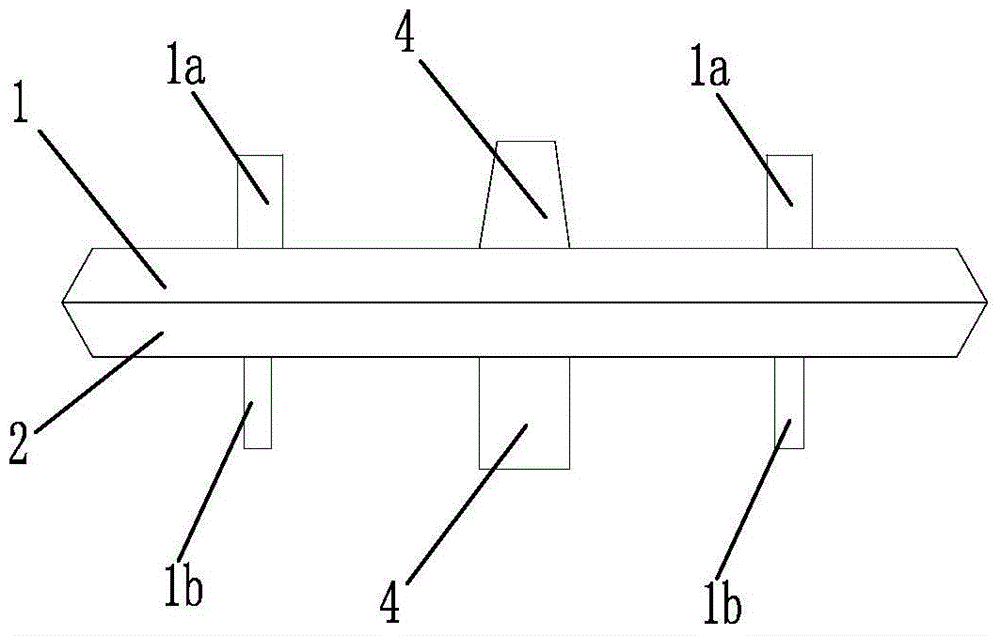

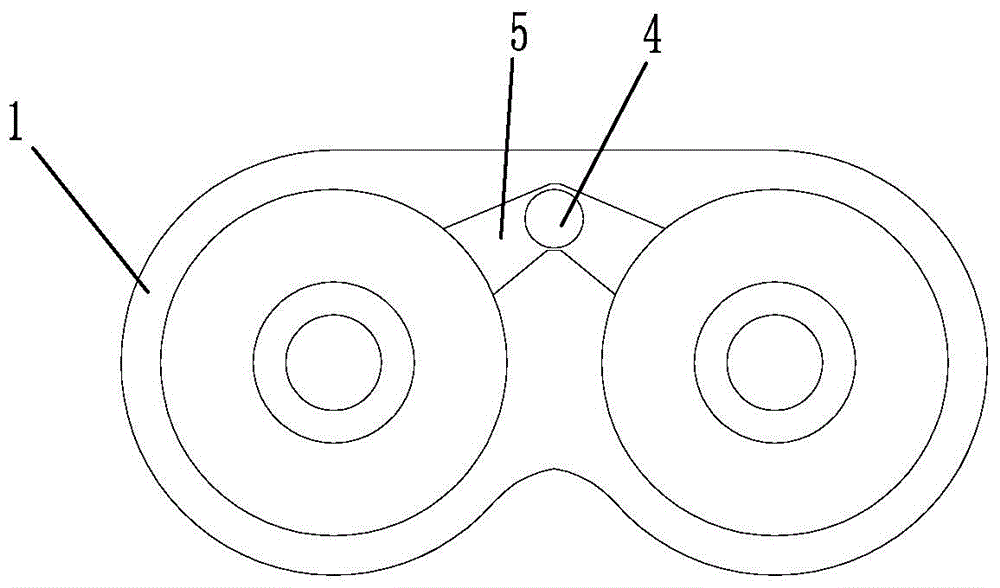

[0016] The upper sand shell 1 and the lower sand shell 2 are buckled together to form two mutually independent mold cavities that match the contour of the disc, and the two mold cavities are left and right symmetrical. The upper and lower sand shells 1 and 2 are respectively provided with pouring risers 4, the pouring rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com