Ultrasonic vibration-assisted metal micro die forming device and usage method thereof

An auxiliary metal, ultrasonic vibration technology, applied in forging/pressing/hammer devices, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problem of limited forming feature size, insufficient microstructure filling, increased friction, etc. problem, to achieve the effect of reducing the feature size, avoiding the phenomenon of streamline cutting, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

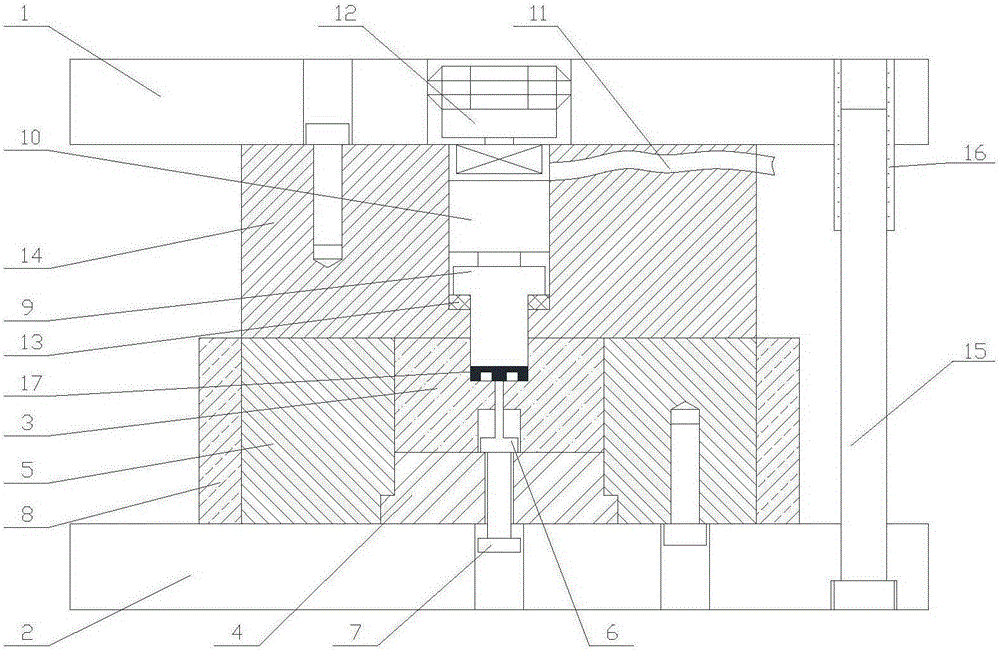

[0024] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the present invention includes an upper mold base 1, a lower mold base 2, a die 3, a die backing plate 4, a die fixing plate 5, an ejector rod 6, an ejection screw 7, a heating ring 8, and a punch 9 , piezoelectric ceramics 10, high-frequency power supply 11, pressure sensor 12, butterfly spring 13, punch fixing plate 14, multiple guide posts 15 and guide sleeve 16, upper mold base 1 and lower mold base 2 are arranged in parallel, and lower mold base A plurality of guide pillars 15 are arranged around the seat 2, one end of each guide pillar 15 is set on the bottom end surface of the lower mold base 2, and the other end is slidingly arranged in the guide sleeve 16, and the guide sleeve 16 is arranged on the upper mold base 1. The die fixing plate 5 is arranged on the lower die base 2, on which there is a die mounting hole, the die backing plate 4 is set in the die mounting hole, and the di...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 Describe this embodiment, the ultrasonic vibration-assisted metal micro-molding forming device described in this embodiment includes a ejector mechanism, which is composed of a ejector rod 6 and an ejector screw 7. Pass through the lower die base 2 and the die backing plate 4 in turn to abut against the lower end surface of the ejector rod 6.

[0026] The technical effect of this embodiment is: the ejector mechanism in this embodiment plays the role of pushing out the micro-molding part 17 during the micro-molding process. After the micro-molding is completed, the pressure is applied to the ejector rod 6 by tightening the ejection screw 7 , Push out the formed micro-molded part 17.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 Describe this embodiment, the ultrasonic vibration assisted metal micro-molding forming device in this embodiment includes a heating device, the heating ring 8 is enveloped on the periphery of the die fixing plate 5, and the mold and the blank are heated to the blank forging temperature by the heating ring 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com