Lubricating oil and uses thereof

A lubricant and lubricant composition technology, applied in the direction of lubricant composition, petroleum industry, base materials, etc., can solve problems such as not considering the properties of high-temperature lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

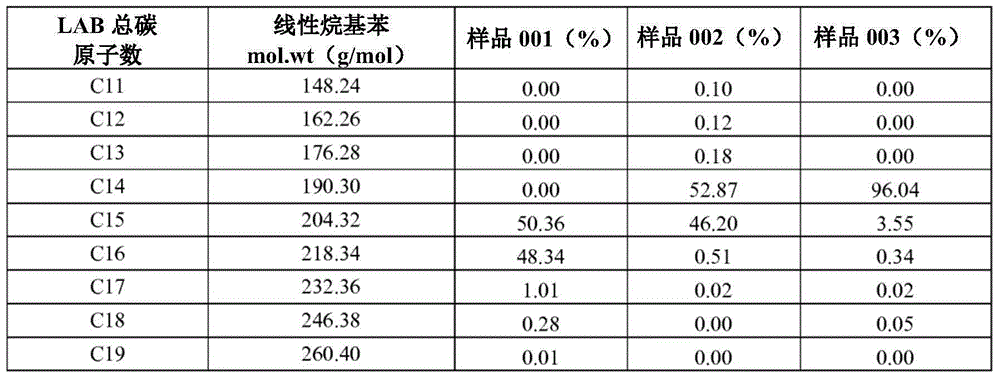

[0045] Examples of linear alkylbenzene oils of the present disclosure are as follows:

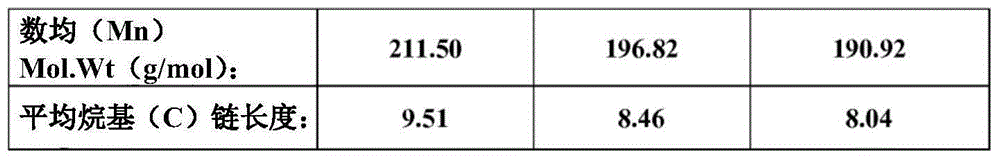

[0046] Sample 001: Linear alkylbenzene (LAB) with an average alkyl chain length of 9.51 carbon atoms and an average molecular weight of 211.50 g / mol.

[0047] Sample 002: Linear alkyl benzene (LAB) with an average alkyl chain length of 8.46 carbon atoms and an average molecular weight of 196.82 g / mol.

[0048] Sample 003: Linear alkyl benzene (LAB) with an average alkyl chain length of 8.04 carbon atoms and an average molecular weight of 190.92 g / mol.

[0049] Table 1 shows the specific C distributions of the three examples.

[0050] Table 1

[0051]

[0052]

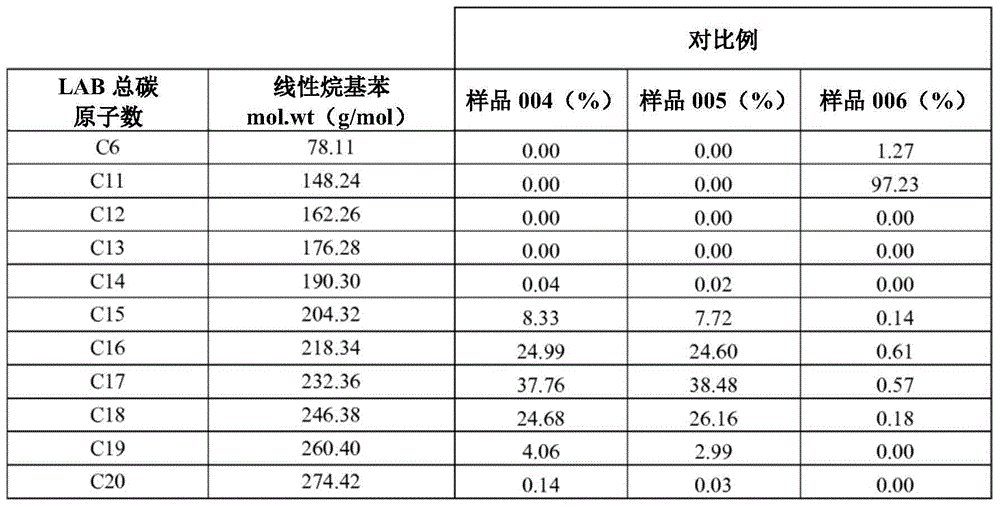

[0053] The following is a comparative example:

[0054] Sample 004: Linear alkyl benzene (LAB) with an average alkyl chain length of 10.91 carbon atoms and an average molecular weight of 231.16 g / mol.

[0055] Sample 005: Linear alkyl benzene (LAB) with an average alkyl chain length of 10.92 carbon atoms and an average molecular weight of 231.25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com