Article comprising a natural fabric and a patterned wicking barrier

A technology of fabrics and products, applied in the direction of fabrics, textiles, papermaking, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

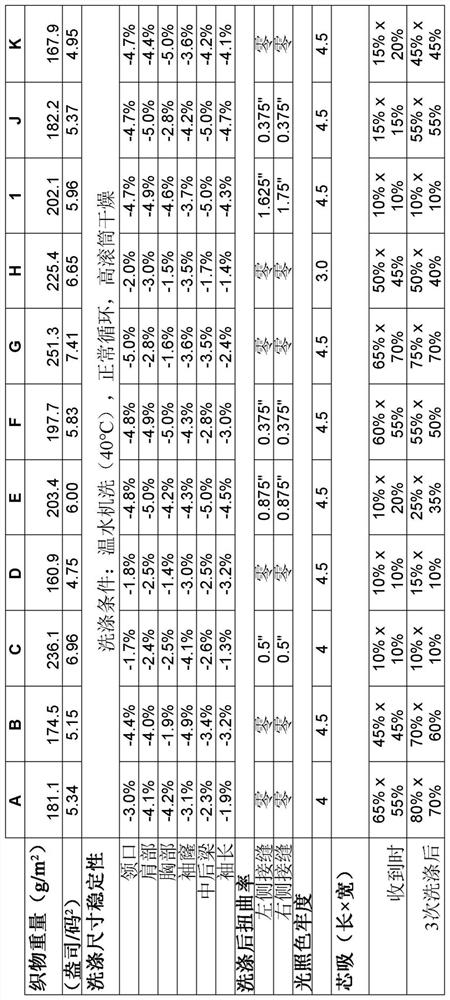

[0021] Example 1: 100% cotton; fabric weight 225g / m 2 -

[0022] Dimensional Change After Laundering - AATCC 135-2018; machine wash at 80°F, normal cycle, Tide ultra powder detergent, then tumble dry, delicate cycle: Length: -1.5%; Width: -0.9%.

[0023] Water Vapor Transmission Rate - ASTM E96 / E96M-15 Procedure B Result: 2893.30 g.day / m 2

[0024] Liquid Moisture Management Properties of Textile Fabrics - AATCC 195-2017: One-Way Transport Capacity (R): 243.6879; Level 4.

example 2

[0025] Example 2: 100% cotton; fabric weight 225g / m 2 -

[0026] Dimensional Change After Wash - AATCC 135-2018; Machine wash normal cycle at 80°F, Tide Supercharged Laundry Detergent, then tumble dry gentle cycle: Length: -1.9%; Width: -0.7%.

[0027] Water Vapor Transmission Rate - ASTM E96 / E96M-15 Procedure B Result: 2714.3 g.day / m 2

[0028] Liquid Moisture Management Properties of Textile Fabrics - AATCC 195-2017: One-Way Transport Capacity (R): 256.3935; Level 4.

example 3

[0029] Example 3: 100% cotton; fabric weight 225g / m 2 -

[0030] Dimensional Change After Wash - AATCC 135-2018; Machine wash normal cycle at 80°F, Tide Supercharged Laundry Detergent, then tumble dry gentle cycle: Length: -2.0%; Width: -0.0%.

[0031] Anti-pilling: Random tumble, after three washes - ASTM D3512 / D3512M-16 After three washes: After 30 minutes, average: 4.5

[0032] Water Vapor Transmission Rate - ASTM E96 / E96M-15 Procedure B Result: 2712.25 g / m 2 / 24 hours

[0033] Liquid Moisture Management Properties of Textile Fabrics - AATCC 195-2017: One-Way Transport Capacity (R): 297.2794; Level 4.

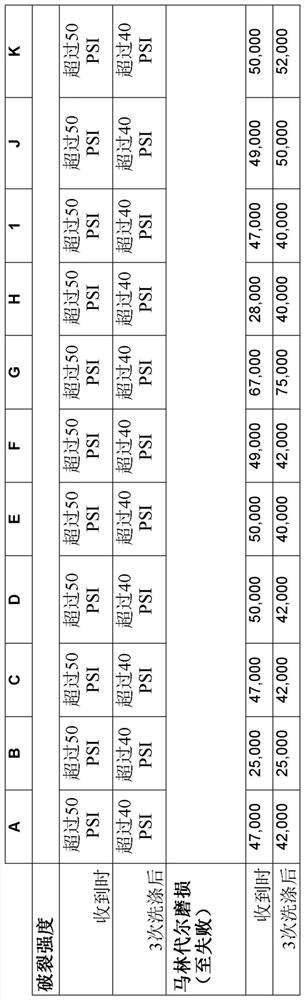

[0034] Examples 1-3 above are non-limiting and are for illustration only. As shown, the present disclosure can produce articles that exhibit improved durability over conventional articles. For example, an article may include a body formed from a pre-shrunk natural fabric; and a wicking barrier printed on a first surface of the fabric in a pattern defining adjacent print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com