Superhydrophilic coating composition

A technology of hydrophilic coating and composition, applied in the field of transparent hydrophilic coating, can solve problems such as affecting the transparency of transparent coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2-

[0042] Example 2 - Clearcoat Coating Composition.

[0043] Table 2 provides representative compositions used to make the hydrophilic coating compositions as set forth above. Coating compatibility and stability are very important for maintaining the clarity of the clearcoat over its lifetime. Any flocculation of nanomaterials can change the particle size distribution and thus the aggregation of particles during the film drying process and will eventually cause whitening and chalking problems of the coated film.

[0044] Table 2.

[0045]

example 3-

[0046] Example 3 - Clearcoat Coating Composition.

[0047]Table 3 provides another representative composition for making the hydrophilic coating composition as set forth above. Note, 1.5% silica / binder is added.

[0048] table 3.

[0049]

[0050] Example 4 - Clearcoat Coating Composition.

[0051] Table 4 provides another representative composition for making the hydrophilic coating composition as set forth above.

[0052] Table 4.

[0053]

[0054] Example 5 - Clearcoat Coating Composition.

[0055] Table 5 provides another representative composition for making the hydrophilic coating composition as set forth above. Inorganic nanoparticles and photocatalytic metal oxide particles generally have hydrophobic surfaces. Surface treatment of these particles with silane coupling agents can modify the surface characteristics to allow for easier dispersion into water-based coating systems. These silane coupling agents have methoxy and ethoxy groups at one end, which can...

example 6

[0058] Example 6 - Simple composition for making a superhydrophilic coating:

[0059] The simplest formulation is provided in Table 2 to provide guidance for bringing together the main components, and therefore additives are skipped in the table. To make this simple recipe shown in Table 2, a VWRVOS16 electric overhead stirrer and 4 blade propeller mixing blades were used. First, add the silica sol to the container and start the mixer at 4 or greater on the dial to get a good mix. While mixing, slowly add the organic binder, mix for about 5 minutes to get a homogeneous mixture, and then add the photocatalytic TiO 2 Dispersion, mix for about 5 minutes to about 10 minutes to obtain a clear or translucent dispersion, adding water as a final item to equilibrate the formulation to the desired solids level. Mixing was continued for another 10 minutes to complete.

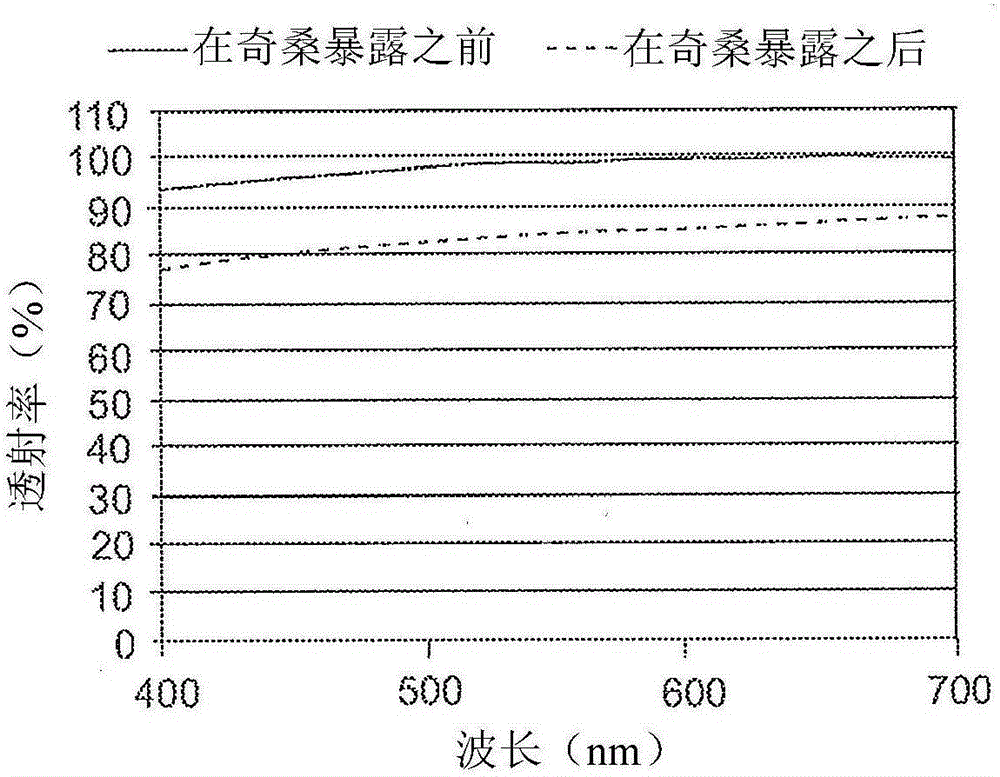

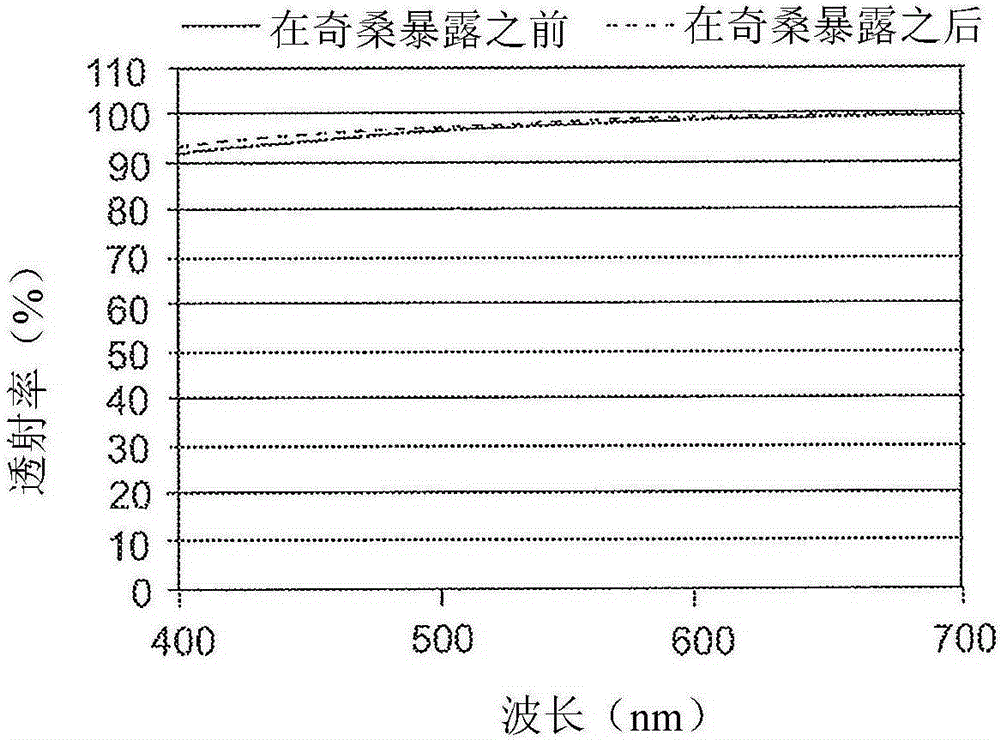

[0060] Clearcoat coatings dry to a clear film under ambient conditions. After sunlight exposure, the transparent fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com