Electrolyte for improving cycle performance of anode materials of lithium-ion batteries

A lithium-ion battery and negative electrode material technology, applied in the field of graphite negative electrode, electrolyte solution for improving the cycle performance of carbon negative electrode, silicon-based negative electrode and tin-based negative electrode, can solve the problems of complex process, high cost, low repeatability, etc., and achieve improvement Effects of cycle performance, reduction of membrane resistance, and improvement of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

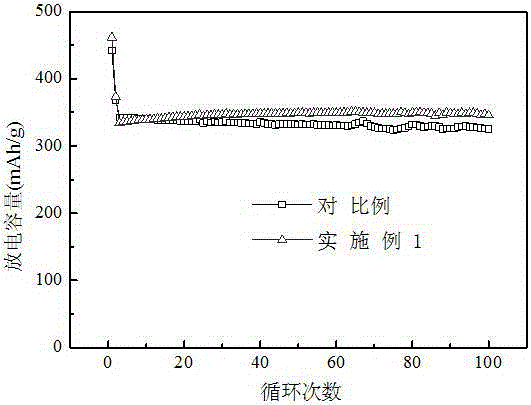

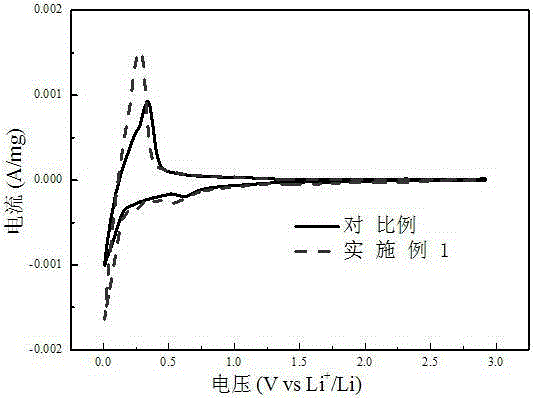

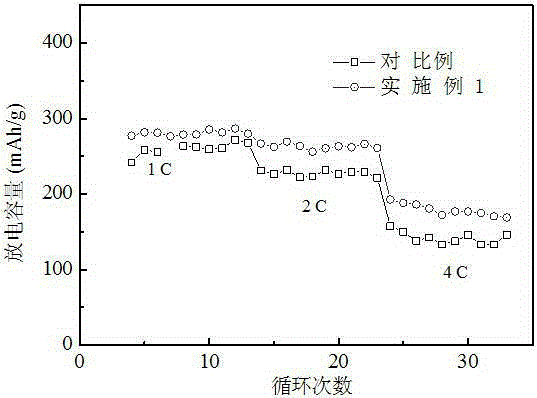

Embodiment 1

[0018] Mix ethylene carbonate (EC) and dimethyl carbonate (DMC) (the mass ratio of EC to DMC is EC:DMC=1:2), remove water and impurities with molecular sieve, and dissolve 1mol / L lithium hexafluorophosphate into the mixed solvent , and then adding 0.5wt% tris(2,2,2-trifluoroethyl) borate (TTFEB) to obtain the lithium-ion battery electrolyte.

Embodiment 2

[0020] Mix ethylene carbonate (EC) and dimethyl carbonate (DMC) (the mass ratio of EC to DMC is EC:DMC=3:7), remove water and impurities with molecular sieve, and dissolve 1mol / L lithium hexafluorophosphate into the mixed solvent , and then adding 0.5wt% tris(2,2,2-trifluoroethyl) borate (TTFEB) to obtain the lithium-ion battery electrolyte.

Embodiment 3

[0022] Mix ethylene carbonate (EC) and dimethyl carbonate (DMC) (the mass ratio of EC to DMC is EC:DMC=4:6), remove water and impurities with molecular sieve, and dissolve 1mol / L lithium hexafluorophosphate into the mixed solvent , and then adding 0.5wt% tris(2,2,2-trifluoroethyl) borate (TTFEB) to obtain the lithium-ion battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com