Modified carbon nano tube and preparation method thereof, lithium ion battery anode and preparation method thereof and lithium ion battery

A lithium-ion battery, carbon nanotube technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve problems such as poor ionic conductivity of lithium-ion batteries, improve high-rate charge and discharge performance, improve ionic conductivity, and be easy to disperse. on effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the above-mentioned modified carbon nanotube, the method comprising the following steps:

[0038] S1. Contacting and reacting carbon nanotubes with nitric acid to obtain a first mixed solution;

[0039] S2, cooling the first mixed liquid, removing excess nitric acid, and drying to obtain a solid substance;

[0040]S3. Disperse the solid matter obtained in step S2 in water, then add LiX to obtain a second mixed solution, then filter and dry to obtain the modified carbon nanotube;

[0041] where X is CO 3 2- , O 2- , OH - .

[0042] According to the method for preparing modified carbon nanotubes provided in the present invention, preferably, the mass concentration of the nitric acid is 15%-40%. Nitric acid within this concentration range can prepare carbon nanotubes in which part of the vacancy defects are oxidized and part of the vacancy defects are not oxidized, and only then can the carbon nanotubes with ...

Embodiment 1

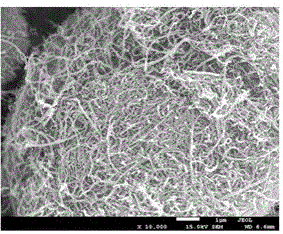

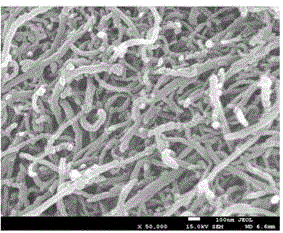

[0069] 1. Preparation of modified carbon nanotubes

[0070] (1) After mixing carbon nanotubes and dilute nitric acid (mass concentration: 15%) at a ratio of 1:5, reflux at 100°C for 120 minutes to obtain a mixed solution;

[0071] (2) After cooling the above mixture, filter it, and wash it with deionized water several times until the pH of the supernatant is 6.0;

[0072] (3) After drying the obtained carbon nanotube solids, mix them with deionized water at a ratio of 1:5 and stir evenly, add a certain amount of LiOH solids, and adjust the pH of the mixture to 7.5;

[0073] (4) The above mixed solution was refluxed and boiled at 100° C. for 20 minutes, the mixed solution was cooled, filtered, washed with deionized water for 3 times, and the solid was dried to obtain the modified carbon nanotube A1.

[0074] 2. Preparation of positive electrode for lithium-ion battery

[0075] (1) Add the dispersant to the solvent and stir for 10 minutes to completely dissolve; then add carbo...

Embodiment 2

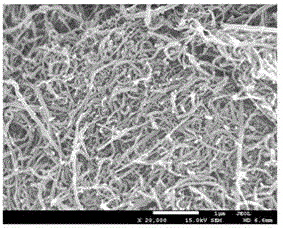

[0086] 1. Preparation of modified carbon nanotubes

[0087] (1) After mixing carbon nanotubes and dilute nitric acid (mass concentration: 30) in a ratio of 1:10, reflux at 150°C for 30 minutes to obtain a mixed solution;

[0088] (2) After cooling the above mixture, filter it, and wash it with deionized water several times until the pH of the supernatant is 6.5;

[0089] (3) After drying the obtained carbon nanotube solids, mix them with deionized water at a ratio of 1:3 and stir evenly, and add a certain amount of Li 2 CO 3 solid, adjust the pH of the mixture to 8.0;

[0090] (4) The above mixed solution was refluxed and boiled at 150° C. for 10 minutes, the mixed solution was cooled, filtered, washed with deionized water for 3 times, and the solid was dried to obtain the modified carbon nanotube A2.

[0091] 2. Preparation of positive electrode for lithium-ion battery

[0092] (1) Add the dispersant to the solvent and stir for 30 minutes until completely dissolved; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com