Polyaniline nanometer tube array/graphene composite material electrode and manufacturing method and application thereof

A technology of nanotube arrays and composite materials, applied in the field of new energy products, can solve the problems of limited use conditions, safety problems, unsafe behaviors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

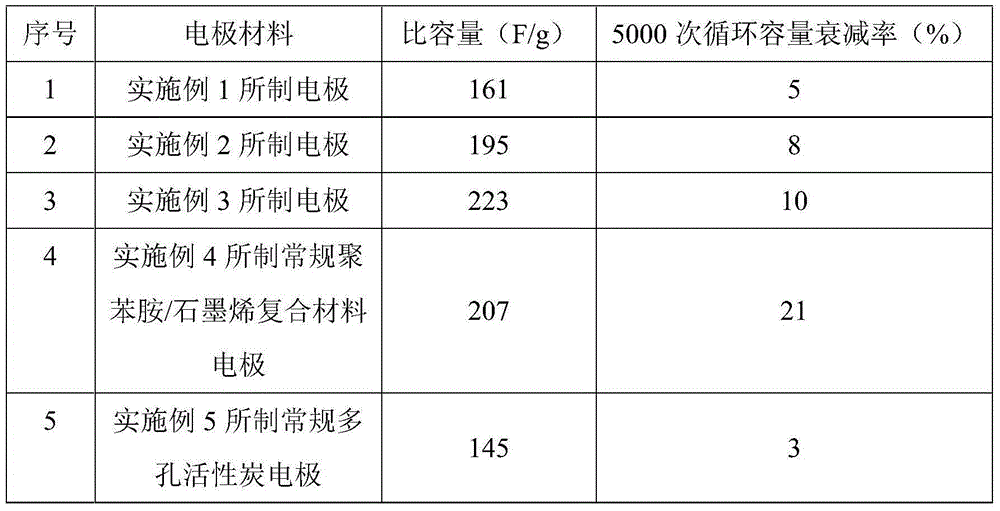

Examples

preparation example Construction

[0030] A preparation method of a polyaniline nanotube array / graphene composite electrode, comprising the following steps:

[0031] Step 1, preparing graphene oxide-doped polyaniline nanotube arrays: uniformly disperse graphene oxide in aniline sulfuric acid solution, then immerse the AAO template in the above solution, vacuumize under reduced pressure, and ultrasonically vibrate; The solution is slowly added dropwise into the sulfuric acid solution of aniline, reacted in a constant temperature water bath at -20-20°C for 1-24h, and the graphene oxide-doped polyaniline / AAO nanocomposite structure is obtained; the graphene oxide-doped polyaniline / AAO nanocomposite structure is invaded In sodium hydroxide solution, heat at 50-70° C. for 10-60 minutes, take it out, wash it with deionized water, and dry it to prepare a graphene oxide-doped polyaniline nanotube array. Wherein, the mass ratio of graphene oxide to aniline is 1:4-19; the molar ratio of the aniline to ammonium persulfate...

Embodiment 1

[0037] (1) Preparation of graphene oxide doped polyaniline nanotube arrays:

[0038] Disperse 0.025g of graphene oxide evenly in 50ml of aniline (0.1mol / L) sulfuric acid (0.5mol / L) solution, and then immerse the AAO (pore diameter 200nm, pore spacing 400nm) template into the above solution, vacuumize under reduced pressure, and ultrasonically Shaking; 50ml of ammonium persulfate (0.1mol / L) sulfuric acid (0.5mol / L) solution was slowly added dropwise into the sulfuric acid solution of aniline, and reacted in an ice-water bath for 6h to obtain a graphene oxide-doped polyaniline / AAO nanocomposite structure; Immerse the graphene oxide-doped polyaniline / AAO nanocomposite structure in 2mol / L sodium hydroxide solution, heat at 50°C for 60min, take it out, wash it with deionized water, and dry it to prepare the graphene oxide-doped polyaniline nanotube array .

[0039] (2) Preparation of polyaniline nanotube array / graphene composite material:

[0040] Add the graphene oxide-doped pol...

Embodiment 2

[0044] Graphene oxide quality in step 1 is 0.052g, other is the same as embodiment 1. In the prepared graphene / polyaniline composite electrode, the graphene content is 10 wt%, and the polyaniline nanotube array content is 90 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com