Surface wave detection method for longitudinal defect on outer surface of small-diameter tube

A technology of longitudinal defects and detection methods, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as small-diameter pipes that are not mentioned, and achieve the effect of improving the detection rate and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

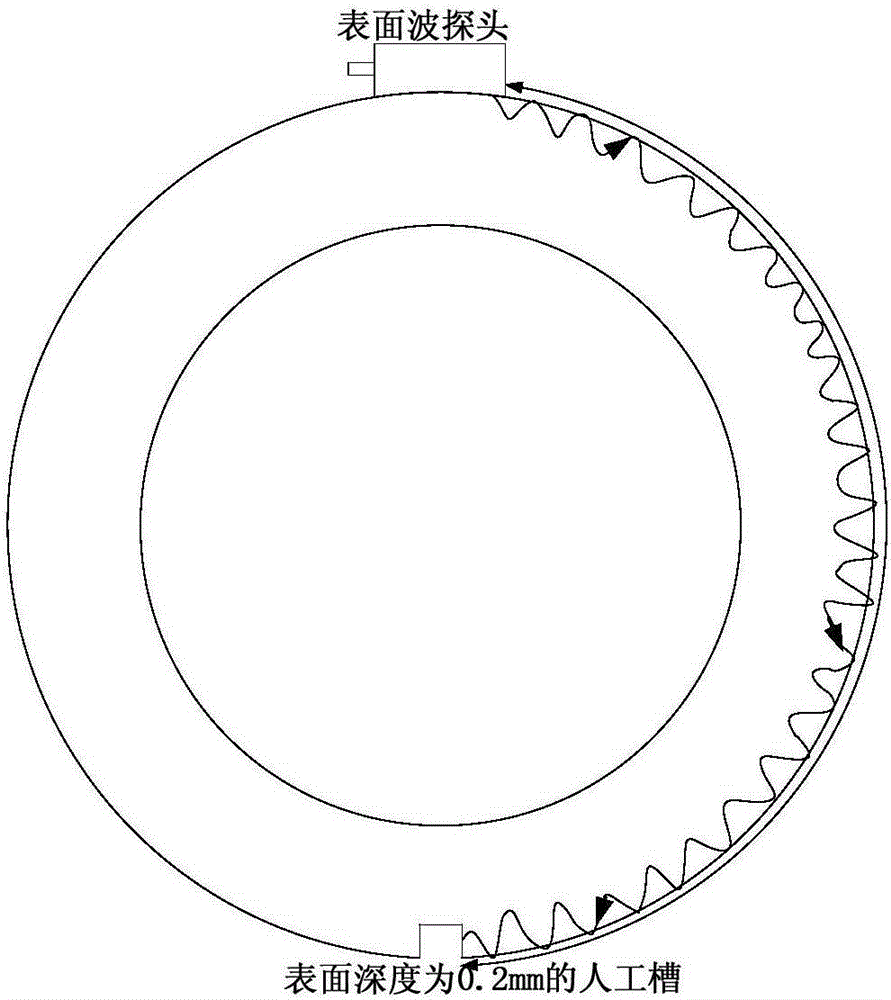

[0030] refer to figure 1 , the surface wave detection method of the longitudinal defect on the outer surface of the small-diameter pipe of the present invention comprises the following steps:

[0031] 1) Clean the rust and foreign matter on the outer surface of the small-diameter tube to be tested, wherein steel wire balls are used to clean the rust and foreign matter on the outer surface of the small-diameter tube to be tested, and then the surface wave probe is coated with coupling agent on the moving area of the small-diameter tube to be tested , wherein the couplant is white vaseline;

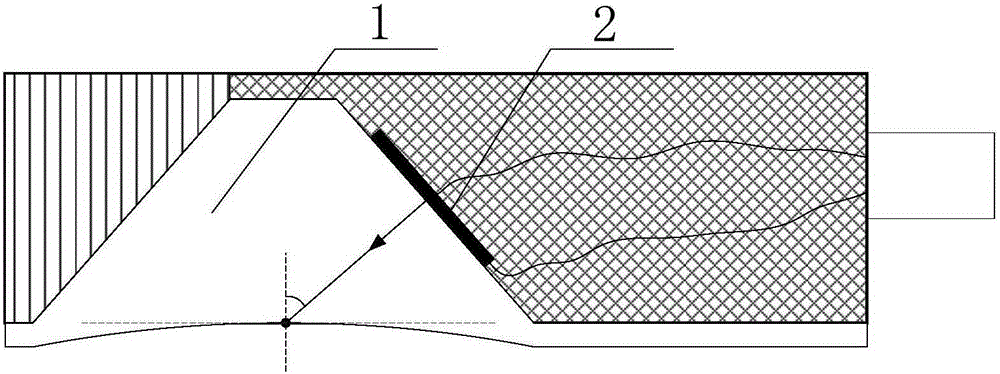

[0032] 2) The chip 2 in the surface wave probe is located on the hypotenuse of the sound-transmitting wedge 1, wherein the bottom surface of the sound-transmitting wedge 1 is a cylindrical concave surface matched with the outer surface of the small-diameter tube to be tested, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com