Testing method for dynamic modulus of bituminous mixture

A technology of asphalt mixture and dynamic modulus, which is applied in the direction of applying repeated force/pulsation force to test the strength of the material, can solve the problems of bead edge damage, complicated operation, limited experimental ability, etc., and solve the problem of the position of the fracture surface, The effect of simple operation and advanced principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the examples and accompanying drawings, but the content of the present invention is not limited to the following examples.

[0020] Asphalt mixture dynamic modulus test method provided by the invention comprises the following steps:

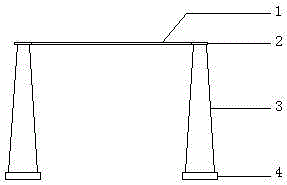

[0021] Step 1: Use a rut forming machine to make a rut plate, and cut a trapezoidal specimen with a fixed size from the rut plate;

[0022] Step 2: Fix the lower bottom of a group (two) trapezoidal specimens on the base, and the upper bottom on the protective crown, and place them together at the test temperature for at least 4 hours;

[0023] Step 3: Install the fixed specimen, base and protective crown together on the loading device, the base is fixed, the horizontal loading rod is connected to the protective crown, and continuous sinusoidal horizontal loads of different frequencies and strain leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com