DF4D internal combustion locomotive connecting rod tooth part repairing and milling combined device

A technology of a diesel locomotive and a combined device, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of large burning tile risk and low alignment accuracy, so as to reduce scrap rate, reduce tile burning risk, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

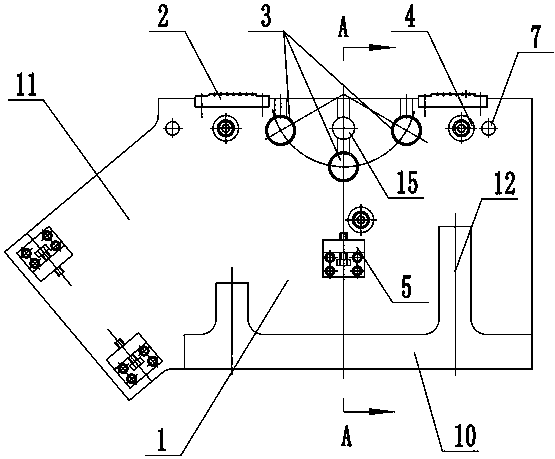

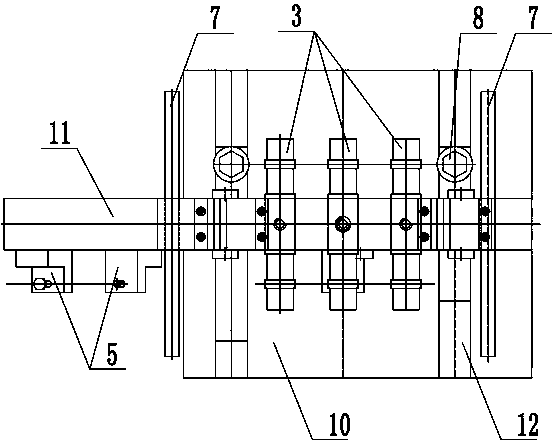

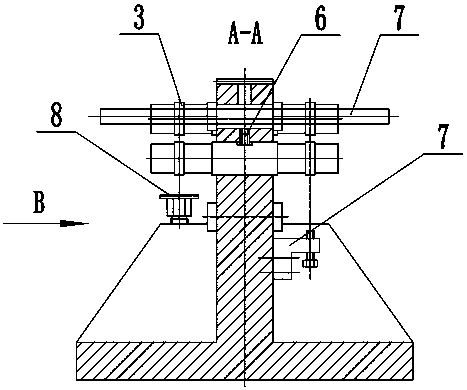

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9As shown, a DF4D diesel locomotive connecting rod tooth repair planing and milling combination device includes: device body 1, tool setting block 2, positioning pin 3, positioning block 4, fine-tuning device 5, positioning screw plug 6, pressure plate support column 7 , adjusting nut 8 and pressing plate 9, described device body 1 is made of base 10, mounting plate 11 and two groups of reinforcing ribs 12 with different heights, mounting plate 11 is vertically and vertically arranged at the center of base 10, two groups of reinforcing ribs 12 are respectively arranged on both sides of the mounting plate, and are perpendicular to the mounting plate 11 and the base 10 respectively, and the three are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com