Mounting method of device for testing pressure at different depths under impact of explosives and powders

A technology of pressure testing and installation method, which is applied in the direction of fuel oil testing, blasting force measurement, material inspection products, etc. It can solve the problems of affecting the measurement results, the sensor is not in close contact with the powder column to be tested, and the measurement results are affected, so as to avoid the signal interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

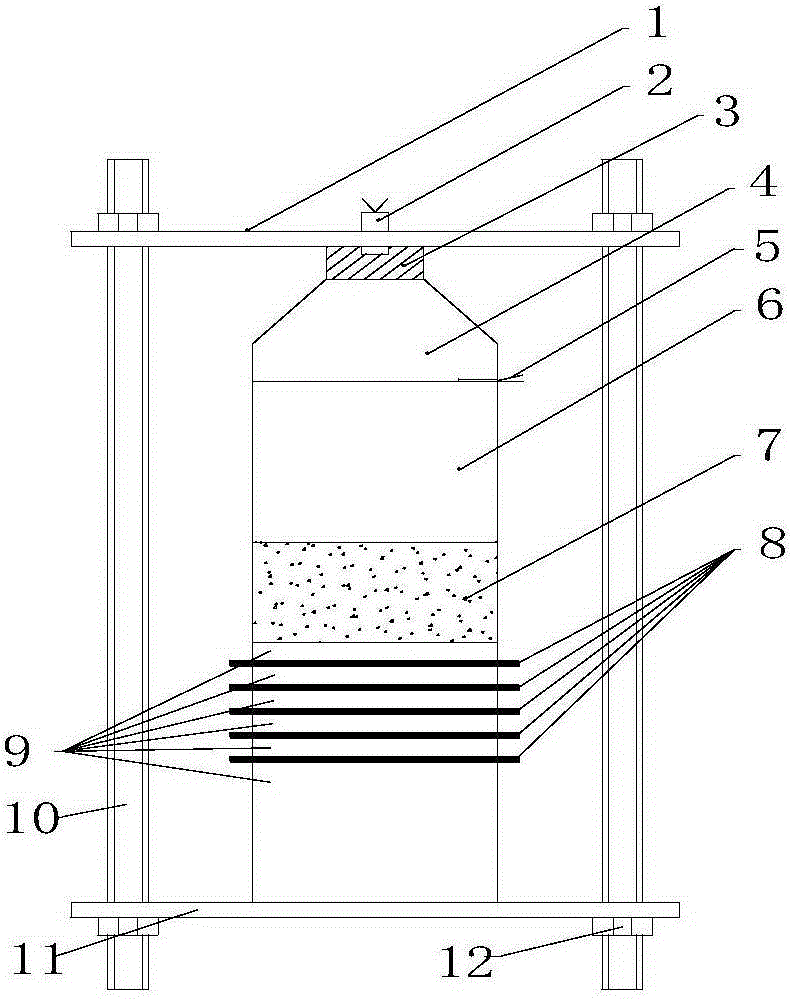

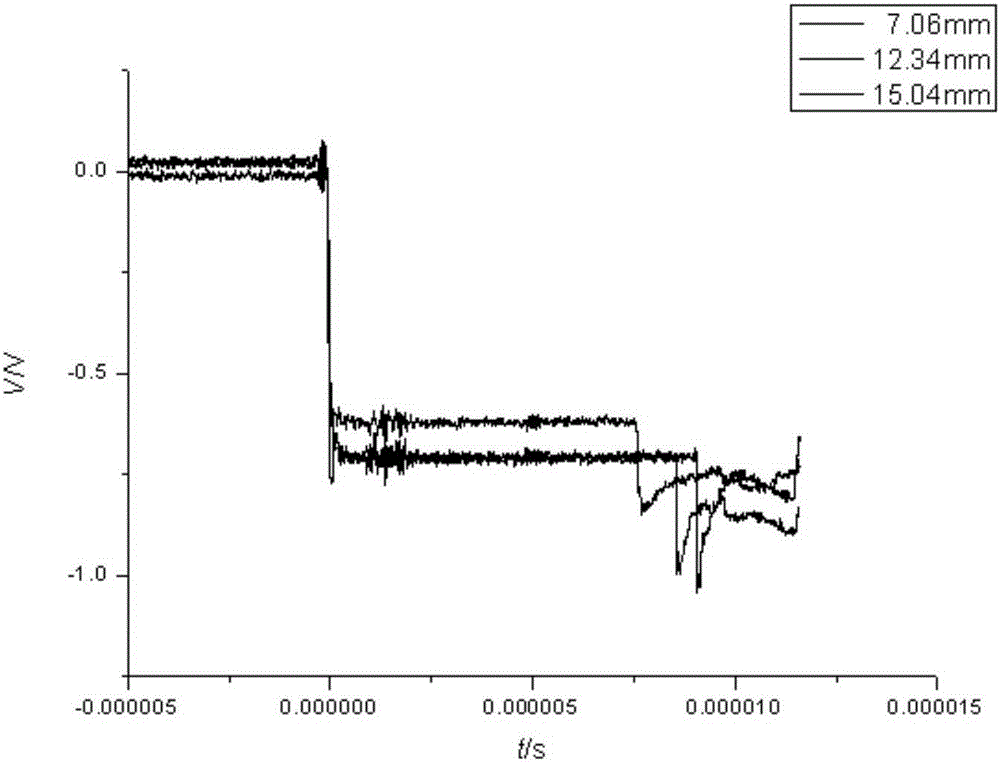

[0040] This embodiment is the installation method of the pressure test device at different depths under the impact of GUHL-2 explosives. The powder columns 9 to be tested are three GUHL-2 tablets with thicknesses of 7.06mm, 5.28mm and 2.70mm, stacked from top to bottom A manganese-copper piezoresistive sensor 8 is embedded between every two tablets, and its assembly method includes the following steps:

[0041] 1) Use a 10x magnifying glass to check whether there are bubbles, impurities and damage in the manganese-copper piezoresistive sensor 8 in the insulated package. If it is unqualified, it should be replaced in time;

[0042] 2) Use 2000-mesh metallographic sandpaper to polish the surface of the drug column 9 to be tested, and then clamp the absorbent cotton with tweezers to wipe the surface of the drug column 9 to be tested;

[0043] 3) The screw rod 10 passes through the threaded hole of the lower fixing plate 11, and the bottom is fixed with nuts 12, and the nuts 12 at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com