Internal temperature on-line monitoring method, device and system for SF6 high-voltage electrical equipment

A technology for high-voltage electrical equipment and internal temperature, which is applied to measuring devices, thermometers, thermometers with physical/chemical changes, etc., and can solve problems such as difficult to measure, inability to measure internal temperature, and inaccurate online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

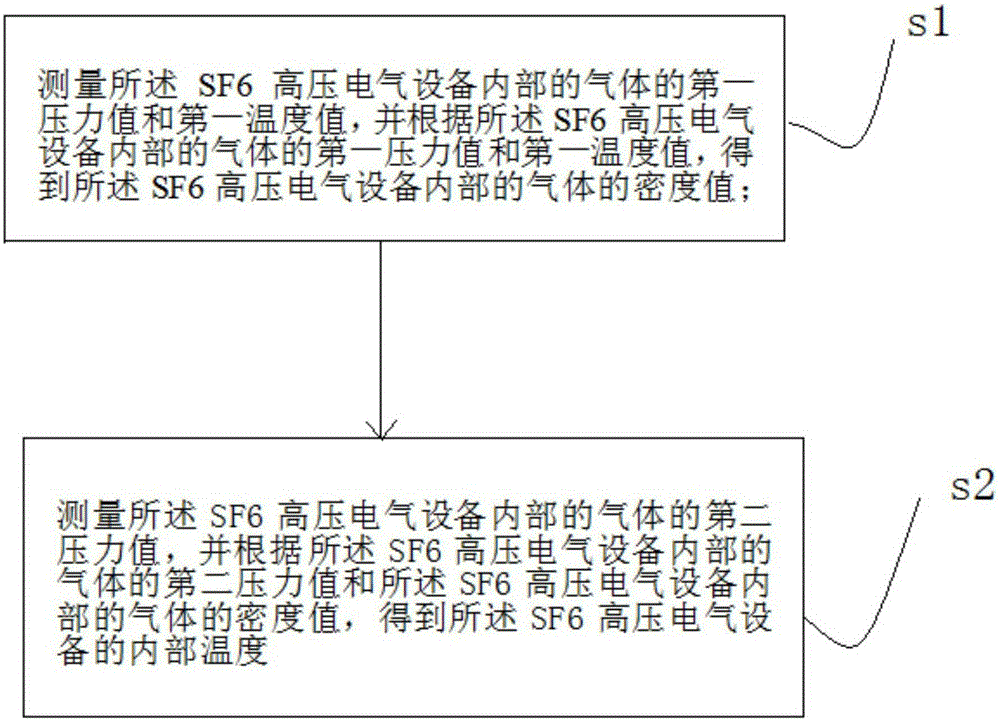

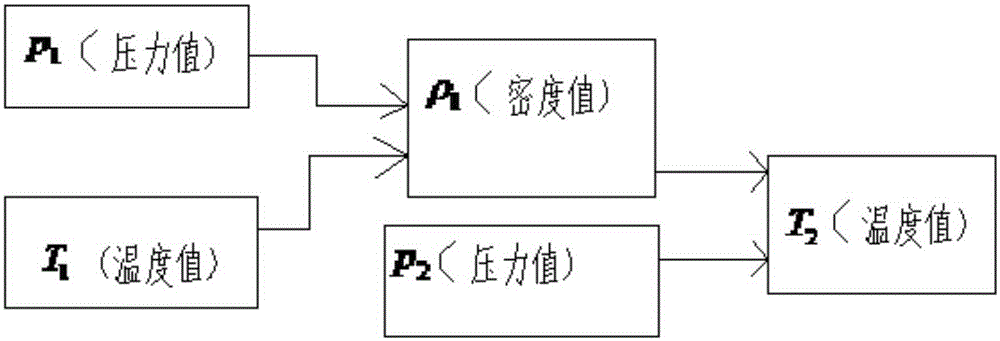

[0074] figure 1 is the SF of a preferred embodiment of the present invention 6 Flow chart of the online monitoring method for the internal temperature of high-voltage electrical equipment; this embodiment provides a SF 6 On-line monitoring method for internal temperature of high-voltage electrical equipment, including:

[0075] S1: Measure the SF 6 The first pressure value and the first temperature value of the gas inside the high-voltage electrical equipment, and according to the SF 6 The first pressure value and the first temperature value (outside temperature) of the gas inside the high-voltage electrical equipment to obtain the SF 6 The density value of the gas inside the high-voltage electrical equipment; its method and principle are: due to the SF 6 High-voltage electrical equipment has good sealing performance, and its density change is an extremely slow process. In a period of time, there is no air leakage, and its internal density remains unchanged. In this way, ...

Embodiment 2

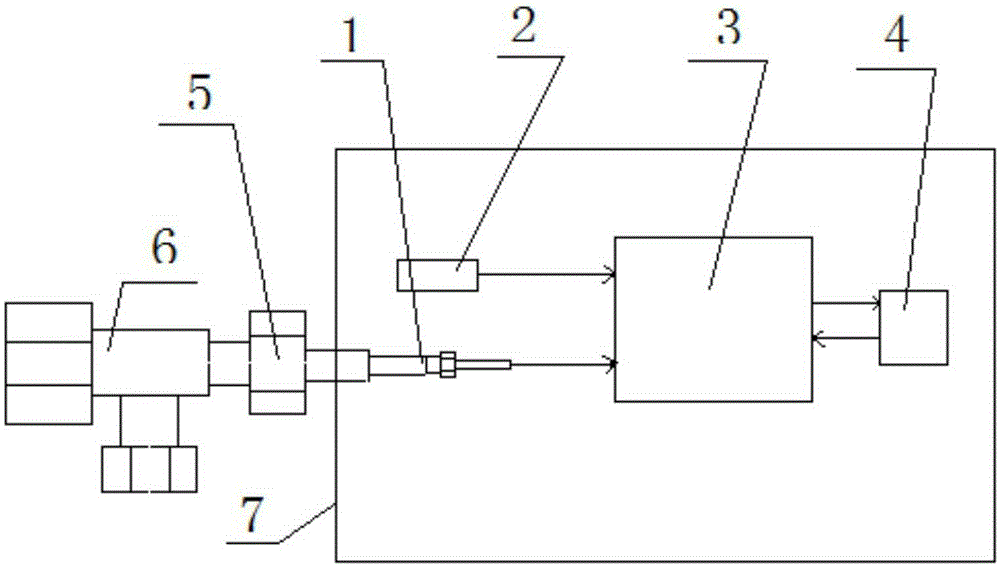

[0097] image 3 shows the SF of this example 6 Schematic diagram of the online monitoring device for internal temperature of high-voltage electrical equipment. This embodiment provides a SF 6 On-line monitoring device for internal temperature of high-voltage electrical equipment, including:

[0098] Housing 7, the housing 7 constitutes the SF to be measured 6 The internal communication space of the high-voltage electrical equipment; the housing is provided with a pressure monitor 1 and a temperature monitor 2; the pressure monitor 1 is used to measure the SF 6 The first pressure value and the second pressure value of the gas inside the high-voltage electrical equipment; the temperature monitor 2 is used to measure the SF 6 The first temperature value of the gas of the high-voltage electrical equipment;

[0099] Also comprise data processing module 3, described data processing module comprises:

[0100] The first computing unit is configured to, according to the SF 6 the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com