Repairing and strengthening method for large cracks on rock tunnel lining

A technology of repairing reinforcement and crack repair, which is applied in the field of geotechnical engineering, can solve the problems that the tunnel lining structure with large cracks is not complete, the tunnel lining has large cracks and even moves up and down, etc., and achieves simple and easy construction and good strengthening effect , the effect of preventing further deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

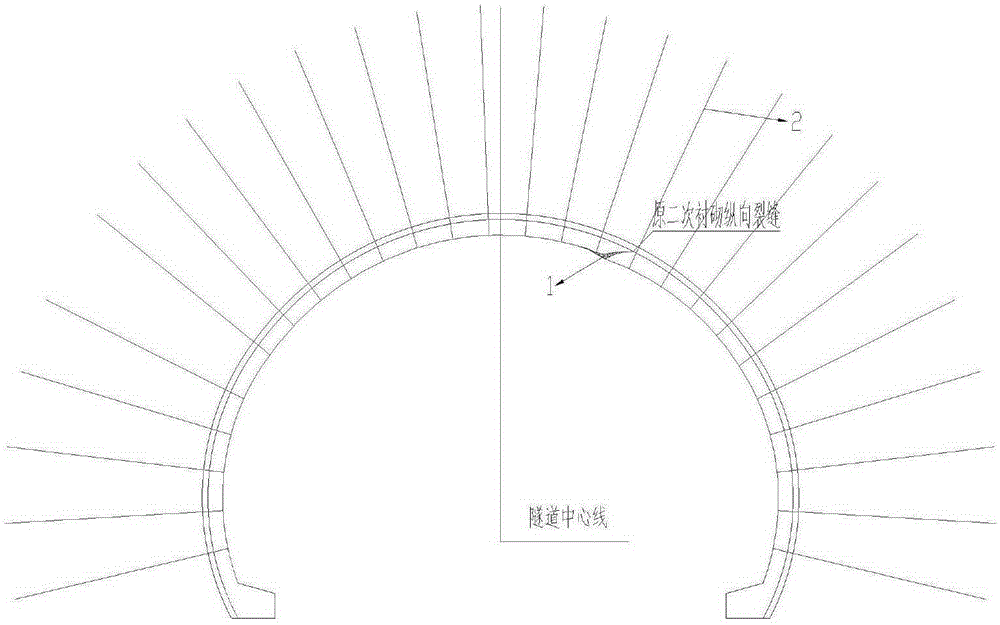

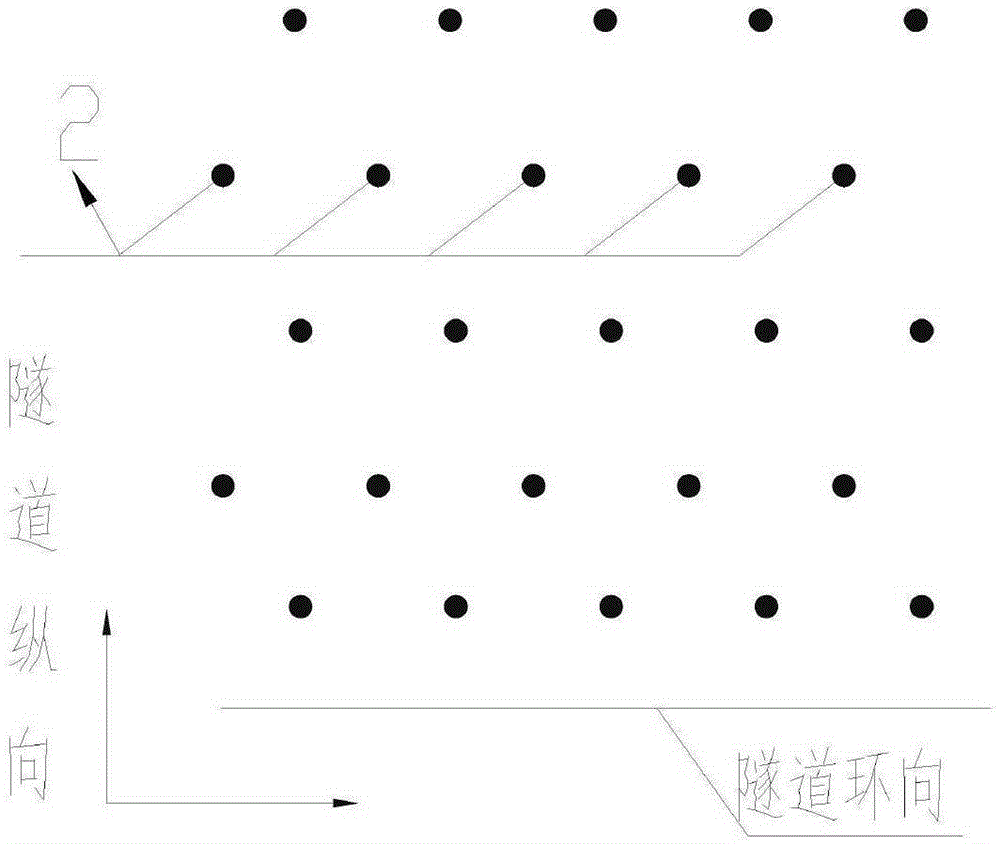

[0031] Three stages are required to complete the repair and reinforcement of large cracks in the rock tunnel lining. First, epoxy resin mortar is used to fill the gaps and cracks in the lining; Thirdly, set a hollow flower tube anchor rod in the center of the bead, and arrange other parts of the anchor rod in a quincunx shape with this as the center.

[0032] (1) Lining misalignment repair:

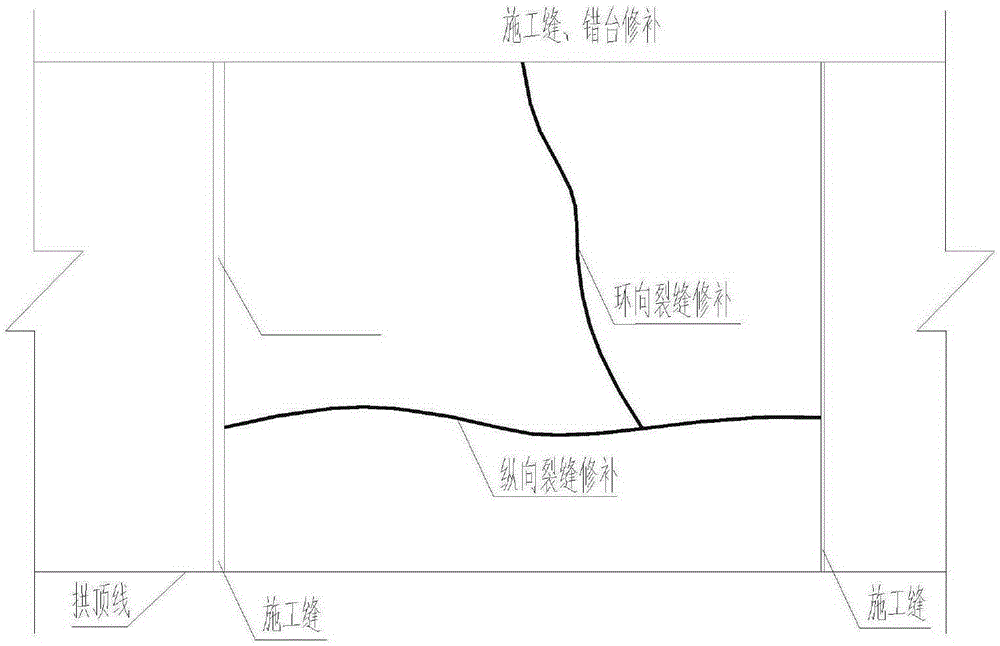

[0033] According to the actual situation of cracks and dislocations in the tunnel lining, the cracked dislocations should be repaired first, and then the general circumferential and longitudinal cracks in the lining should be gradually filled and sealed from one side to the other. The steps are: clean the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com