Method for reinforcing cement column intensity and module used in the same

A cement and column technology, used in building maintenance, building types, buildings, etc., can solve the problems of many repair and strengthening steps, limited strengthening effect, separation, etc., and achieve the effect of saving manpower and material resources and achieving remarkable strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

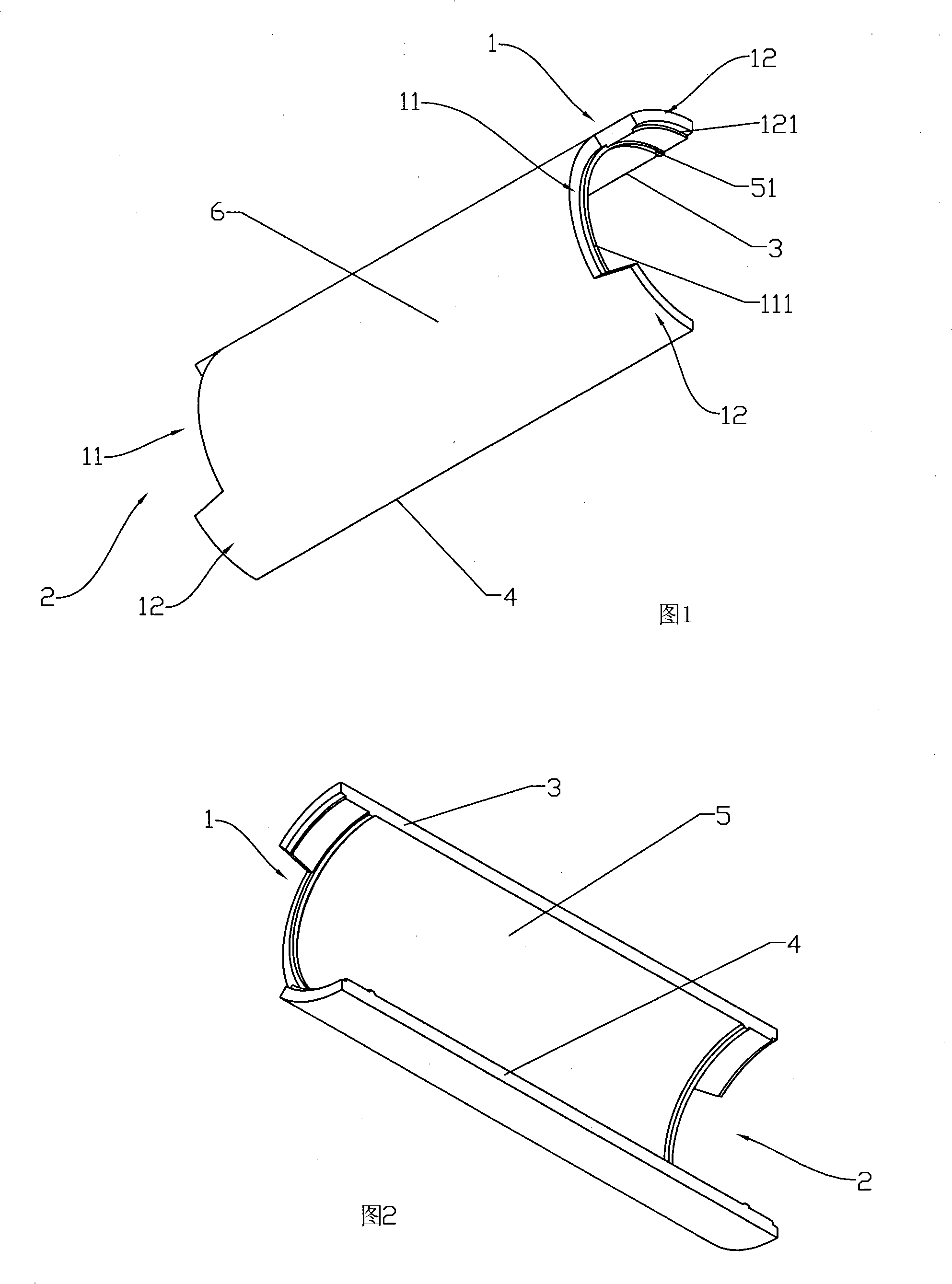

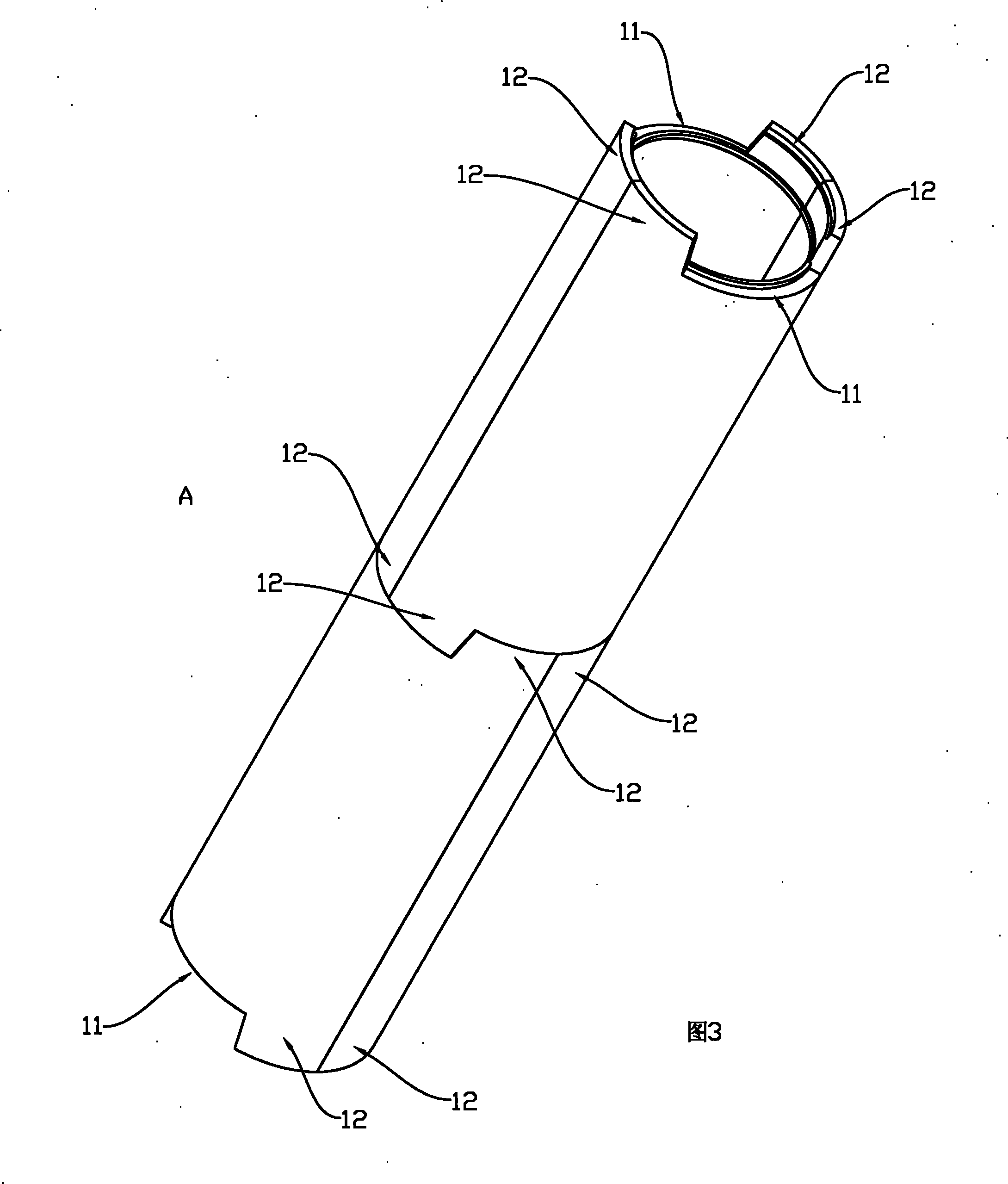

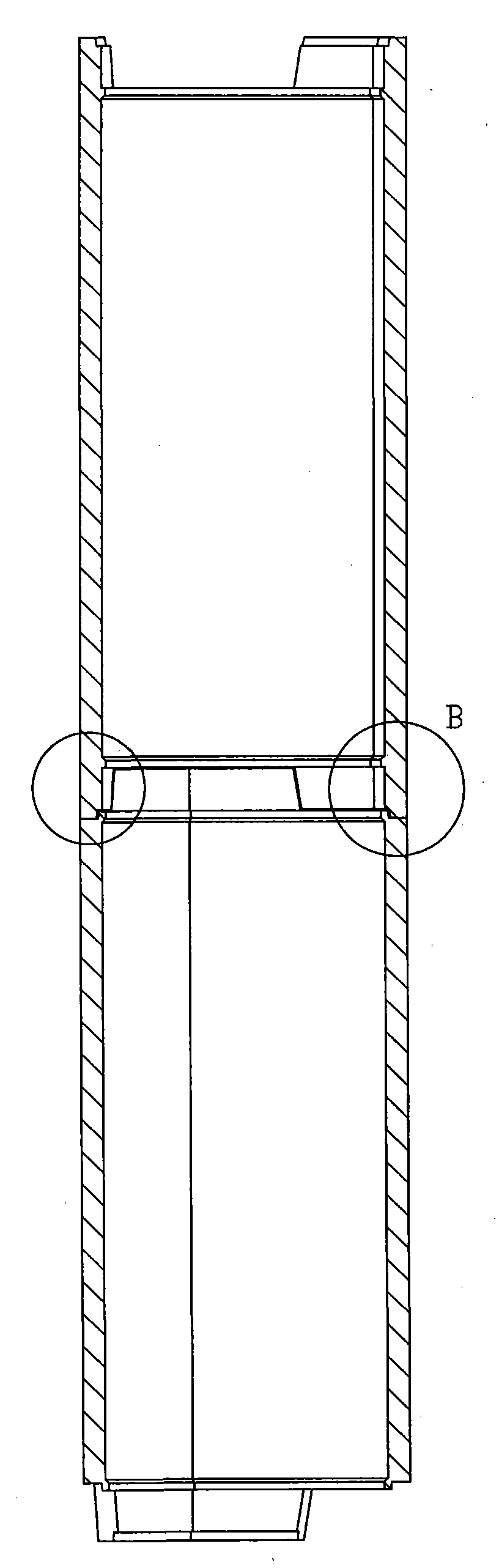

[0038] See Figure 1 to Figure 6, as an embodiment of the present invention, the module for constructing the pouring cavity to strengthen the strength of the cement column includes an upper placement surface 1, a lower placement surface 2, a pair of end surfaces 3 and 4, wherein 3 is the left end surface , 4 is the right end surface, an inner surface 5, an outer surface 6, the inner surface 5 and the outer surface 6 are coaxial semi-cylindrical arc surfaces. There is a recess 11 in the middle of the upper placement surface 1 and the lower placement surface 2, and two convex parts 12 are symmetrically arranged on both sides of each of the recesses 11, and each of the recesses 11 is in the circumferential direction. The length is the sum of the lengths of the two protrusions 12 in the circumferential direction; the protrusions 12 of adjacent modules are formed in a shape suitable for being embedded in the recess 11 and complementarily engaged. A concave platform 121 along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com