Anchor cable and metal support uniting complementing support device and method

A metal bracket and support device technology, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of maintaining the stability of the roadway and the inability of metal brackets to play the supporting advantages, and achieves material saving, complementary defects, and enhanced advantages. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

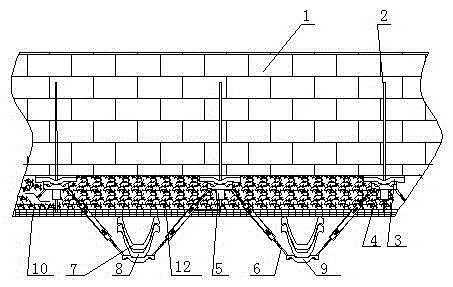

[0049] Such as figure 1 , 2 As shown, the present invention is used for joint complementary support in the process of driving the roadway. The main steps used are: driving the roadway, hanging the metal mesh 10 (install the anchor cable 2 without hanging the net or leave the space for installing the anchor cable tray 3) Yes), set up a U-shaped steel metal bracket 7, drill anchor cables in the middle area of the weak section of the adjacent metal bracket 7, install the anchor cable 2, the tray 3, the anchor cable transfer beam 4, the anchor 5, and give the anchor Apply a pre-tightening force of 100KN~120KN to the cable, install the tie rod body 6a in the tie rod holes on the anchor cable transfer beam 4 and the metal support transfer beam 9, and then add a metal mesh 10 at the location of the anchor cable 2, and then use The double-ended nut 6b is connected with the tie rod body 6a to realize the connection between the metal support transfer beam 9 and the metal support short b...

Embodiment 2

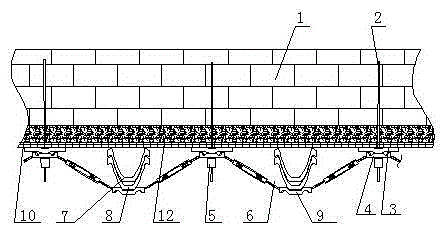

[0051] Such as image 3 As shown, the device of the present invention is used in a roadway where the metal mesh 10 has been tightly filled with the back wall. The implementation method is basically the same as that of the first embodiment. Due to the different application roadways, the installation procedures are changed. The specific procedures are as follows: since the metal mesh 10 and the surrounding rock 1 have been filled with filler 12, the adjacent metal supports 7 Drill a hole in the middle of the weak section. The hole is drilled from the outside of the metal mesh 10 into the surrounding rock 1. Install the anchor cable 2, the tray 3, the anchor cable transfer beam 4, and the anchor 5, and apply pretension to the anchor cable Force 100KN~120KN; connect the tie rod body 6a with the double-ended nut 6b to realize the connection between the anchor cable 2 and the metal support transfer beam 9, the metal support short beam 8 and the metal support 7, and then apply a pre-ti...

Embodiment 3

[0053] As attached Figure 4 As shown, the device of the present invention is used in a roadway that has been racked and sprayed on the surrounding rock surface. The implementation method is basically the same as that of the first embodiment. Due to the different application roadways, the installation procedures are changed. The specific procedures are as follows: the filler 12 has been filled between the metal mesh 10 and the surrounding rock 1, and the outside of the metal mesh 10 has been A shotcrete layer 11 is set, and a hole is drilled in the middle of the weak section of the adjacent metal bracket 7. The hole is drilled from the outside of the shotcrete layer 11 to the surrounding rock 1, and the anchor cable 2, the tray 3, and the anchor cable are installed. Load beam 4, anchor 5, and apply a pre-tightening force of 100KN~120KN to the anchor cable; connect the tie rod body 6a with a double-ended nut 6b to realize the anchor cable 2 and the metal support beam 9, the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com