High-strength non-delaminating template based on hot press molding and preparation method of high-strength non-delaminating template

A hot-press forming, high-strength technology, which is applied in the on-site preparation of building components, formwork/formwork components, chemical instruments and methods, etc., can solve the problems of low cycle times, low cycle times, and shortened service life, etc. problems, achieve the effect of reducing the cost of single use, increasing the number of cycles and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of a high-strength non-delamination formwork formed by thermocompression, the steps of which are:

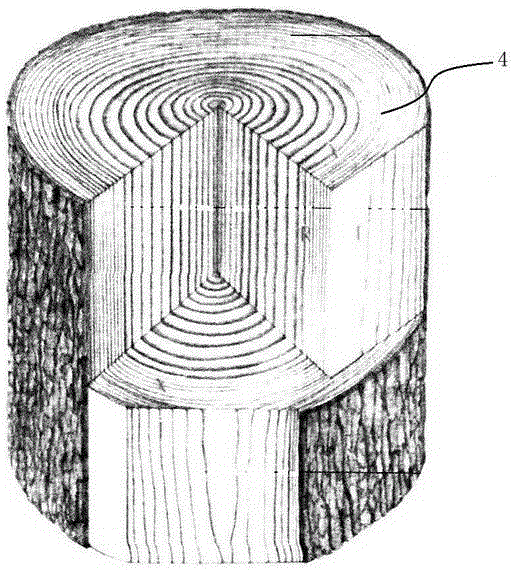

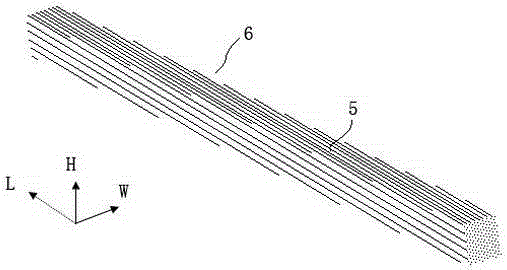

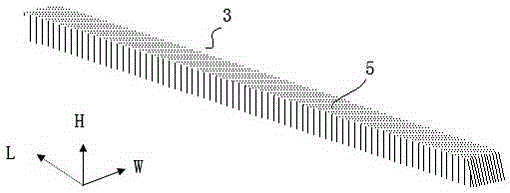

[0028] (1) Preparation of the board core: making wooden materials into cuboid-shaped slats, the slats are divided into slat a6 and slat b3, the length direction of the slat a6 is consistent with the growth direction of the wood, and the height direction of the slat b3 is Consistent with the growth direction of the wood, the lath a6 and the lath b3 are respectively formed by a cuboid wooden strip, or the lath a6 and the lath b3 are respectively spliced along the length direction of the lath by a plurality of wooden strips through the adhesive in the way of miter joint or butt joint Formed, the butt angle is θ=90°, and the miter angle is θ<90°, so as to meet the length and size requirements of the core 1; along the width direction of the slats: Adhesives are used to bond between adjacent slats in the form of butt joints. One piece, the butt joint angl...

Embodiment 1

[0032] In this embodiment, along the direction of the long and wide surface 5 formed by the length and width of the vertical slats, the height of the core 1 is 10 mm, wherein the width of the slats a6 and slats b3 is 2 mm, and the width of the slats b3 is 2 mm. The ratio of the number of slats to the number of slats a6 is 2. The slats a6 and slats b3 are respectively formed by splicing a plurality of wooden slats through the adhesive phenolic resin along the length direction of the slats. The butt joint angle is θ=90°. In the strip width direction, the corresponding same planes of adjacent slats are bonded together by the adhesive phenolic resin, and the butt angle is θ=90°; the continuous fiber composite reinforced surface layer 2 is composed of a layer of continuous fiber reinforced prepreg The fiber direction of this layer of continuous fiber-reinforced prepreg is the same as the width direction of the board core 1. The continuous fiber-reinforced prepreg is composed of cont...

Embodiment 2

[0034] In this embodiment, the ratio of the number of slats b3 to the number of slats a6 is 0.75, and the rest of the content is the same as in Example 1. After mechanical performance tests: the longitudinal static bending strength is 36MPa, the longitudinal modulus of elasticity is 3000MPa, and the transverse The static bending strength is 22MPa, and the transverse elastic modulus is 3000MPa; the water resistance type I peeling performance test: no change; the vertical drop test from a height of 6 meters: no cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com