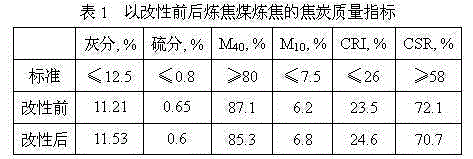

Method for coal coking and blending based on organic sulfur-enriched high sulfur coke and fat coal

A technology of organic sulfur and coking coal, which is applied in the field of coking coal blending by using low-quality high-sulfur coking coal, can solve the problems of restricting the use of high-sulfur coke and fat coal, and affecting the quality of coke, so as to save high-quality coking coal resources and reduce coking Effect of improving cost and coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mass percentage composition of a conventional low-sulfur coking coal is: 30% low-sulfur fat coal, 45% low-sulfur coking coal, 1 / 3 coking coal 10%, and lean coal 15%. After testing its quality index is: volatile matter V daf 25.13%, Ash A d 9.26%, sulfur content S daf 0.75%, the cohesion index G value is 82, and the maximum thickness of the gelatinous layer is Y19mm.

[0027] This embodiment improves the above-mentioned coking coal blending.

[0028] Raw materials for improved use include high-sulfur fertile coal, low-rank bituminous coal and coal tar pitch.

[0029] Quality index of high-sulfur fertile coal: volatile matter V daf 23%, Ash A d 8.6%, sulfur content S daf 3%, the cohesion index G value is 88, and the maximum thickness of the gelatinous layer is Y20mm. Among them, the percentage of organic sulfur content in the total sulfur content is 68wt%.

[0030] Quality index of low rank bituminous coal: volatile matter V daf 38%, sulfur 0.26wt%, ash 9wt%....

Embodiment 2

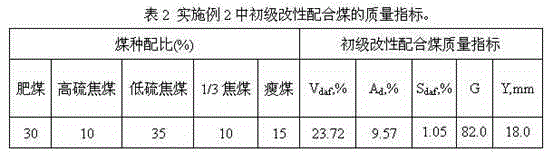

[0040] Low-sulfur coking coal is selected from a blend of fat coal, coking coal, 1 / 3 coking coal, and lean coal, and the blending amounts are 30%, 45%, 10%, and 15% respectively in terms of mass percentage. The high-sulfur coking coal was replaced by low-sulfur coking coal at a ratio of 10%, and the quality indicators of the primary modified blended coal obtained after mixing are shown in Table 2.

[0041]

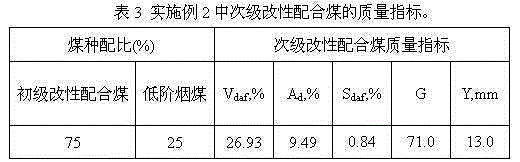

[0042] It can be seen from Table 2 that the sulfur content of the primary modified blend coal does not meet the process requirements of ≤0.9%, and then a low-rank bituminous coal with a volatile content of 38% is selected as a high-volatile non-coking coal, and its sulfur content is 25% % is blended into the primary modified blending coal to obtain the secondary modified blending coal, and its quality indicators are shown in Table 3.

[0043]

[0044] It can be seen from Table 3 that after adding high volatile non-coking coal, the sulfur content of the obtained secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Maximum thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com