Nanoscale high-strength light-diffusion material as well as preparation method and application thereof

A technology of high-intensity light and diffusing materials, applied in the field of nanomaterial processing, can solve the problems of human health, easy bending of materials, eye damage, etc., and achieve the effects of good bending resistance, reduced material thickness, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

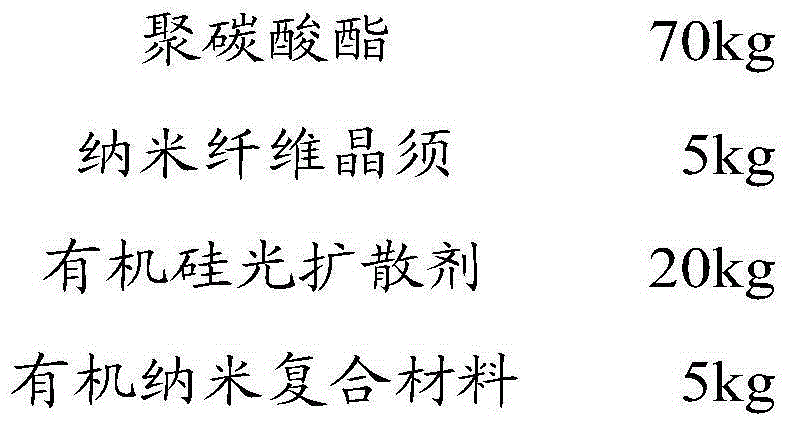

[0030] The raw materials of nano-scale high-intensity light-diffusing materials are as follows:

[0031]

[0032] Concrete preparation process is as follows:

[0033] 1) Put the raw materials into a high-speed mixer for mixing and stirring, stir evenly and control the stirring rate at 700-800rad / min, the stirring time is 20-30min, and then dry in the blast dryer for 2-3h to obtain the mixed material, dry The temperature is controlled at 105-120°C;

[0034] 2) Melt, knead and extrude the mixture through a screw extruder. After extruding at a temperature of 245-320°C, set the temperature of the molding die at 65-80°C for cooling and shaping of the extruded material After shaping, the nanoscale high-intensity light diffusion material of the present invention can be obtained, which can be used to make LED lampshades, lamp tubes, light boxes and liquid crystal displays.

Embodiment 2

[0036] The raw materials of nano-scale high-intensity light-diffusing materials are as follows:

[0037]

[0038]

[0039] Wherein, the ester group of polycarbonate is aliphatic-aromatic;

[0040] Concrete preparation process is as follows:

[0041] 1) Put the raw materials into a high-speed mixer for mixing and stirring, stir evenly and control the stirring rate at 700-800rad / min, the stirring time is 20-30min, and then dry in the blast dryer for 2-3h to obtain the mixed material, dry The temperature is controlled at 105-120°C, and then kept in a drying oven at 70-90°C for 2-3h;

[0042] 2) Melt, knead and extrude the mixture through a screw extruder, set the nozzle temperature to 280-320°C, set the extrusion temperature to 5 temperature gradients, the first gradient is 290-325°C, the second gradient 270-290°C, the third gradient is 260-280°C, the fourth gradient is 245-270°C, the fifth gradient is 230-245°C, and then the temperature of the molding die is set to 70-75...

Embodiment 3

[0044] The raw materials of nano-scale high-intensity light-diffusing materials are as follows:

[0045]

[0046]

[0047] Wherein, the ester group of polycarbonate is aliphatic;

[0048] Concrete preparation process is as follows:

[0049] 1) Put the raw materials into a high-speed mixer for mixing and stirring, stir evenly and control the stirring rate at 700-800rad / min, the stirring time is 20-30min, and then dry in the blast dryer for 2-3h to obtain the mixed material, dry The temperature is controlled at 105-120°C, and then kept in a drying oven at 70-90°C for 2-3h;

[0050] 2) Melt, knead and extrude the mixture through a screw extruder, set the nozzle temperature to 280-320°C, set the extrusion temperature to 5 temperature gradients, the first gradient is 290-325°C, the second gradient 270-290°C, the third gradient is 260-280°C, the fourth gradient is 245-270°C, the fifth gradient is 230-245°C, and then the temperature of the molding die is set to 70-75°C for ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com