Comprehensive recovery method for effective ingredients in 7-amidogen cephalosporins alkanes acid crystallization mother liquor produced through enzymatic hydrolysis method

An aminocephalosporanic acid and recovery method technology, applied in the pharmaceutical field, can solve problems such as high treatment costs, and achieve the effects of reducing emissions, reducing costs, and realizing environmental protection, clean and green production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

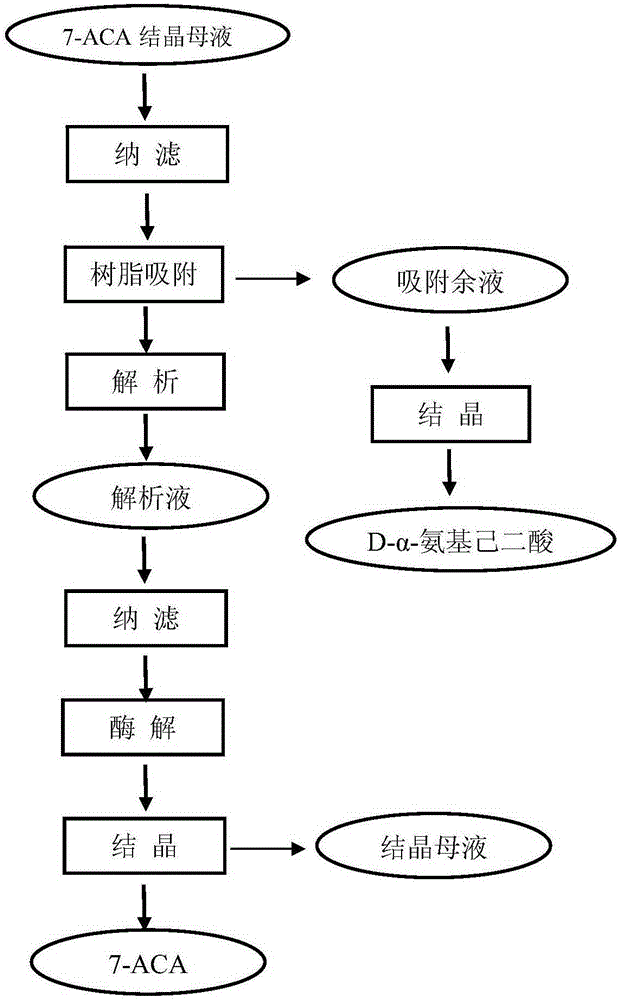

Method used

Image

Examples

preparation example Construction

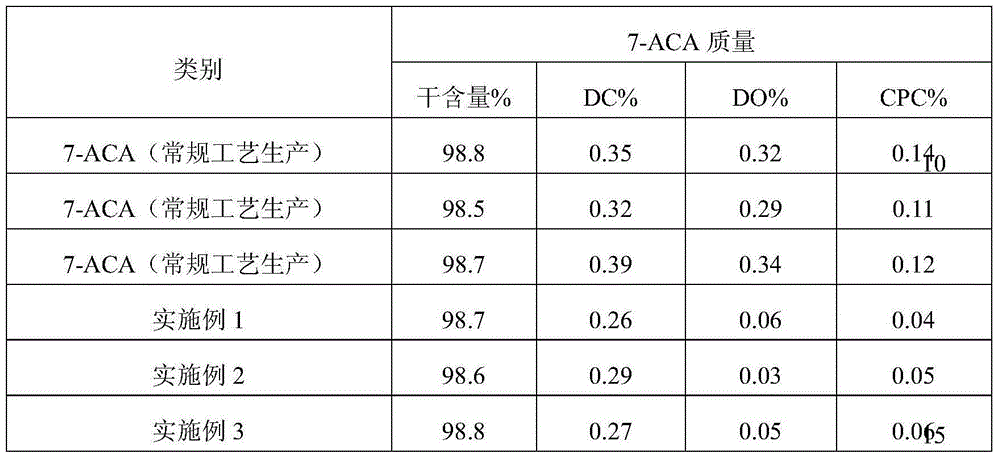

[0033] In the preparation of the step (4) 7-ACA, the analytical solution obtained in the above step (2) is concentrated by using a nanofiltration membrane with a molecular weight cut-off of 150 to 300 Daltons to obtain a concentrated solution; Add immobilized cephalosporin C acylase, at pH 8.00-8.60, temperature 5-30°C, crack CPC in the concentrated solution; after the cleavage, filter to remove immobilized cephalosporin C acylase , the resulting filtrate was adjusted to pH 3.00-5.50 with acid, and 7-ACA crystals were precipitated to obtain 7-ACA crystals.

[0034] Among them, the concentration of 7-ACA in the analysis solution obtained in the above step (2) is about 5.0 to 10.0 g / L, which does not reach the concentration required for crystallization, and needs to be concentrated to 15.0 to 25.0 g / L through a nanofiltration membrane, preferably 20.0 to 25.0 g / L. g / L; the nanofiltration membrane should choose a nanofiltration membrane with a molecular weight cut-off of 100-300 ...

Embodiment 1

[0039] According to the following steps, the active ingredient in the 7-ACA crystallization mother liquor produced by the enzymatic cleavage method is comprehensively recovered:

[0040] (1) Preparation of 7-ACA mother liquor concentrate

[0041] Take 20.0L of the 7-ACA crystallization mother liquor after 7-ACA crystallization separation, the concentration of 7-ACA in the mother liquor is 1.1g / L, the concentration of D-α-aminoadipic acid is 11.6g / L, the concentration of CPC is 0.3g / L, pH5 .19.

[0042] Slowly adjust the above-mentioned 7-ACA crystallization mother liquor with 15wt% sodium hydroxide solution until the solution is clear, and the pH is adjusted to 7.10, and then use a nanofiltration membrane with a molecular weight cut-off of 160 Daltons to store the 7-ACA crystallization mother liquor at 5-8°C Concentrate to 2.0L, wherein the concentration of 7-ACA is 10.6g / L, the concentration of D-α-aminoadipic acid is 113.3g / L, and the concentration of CPC is 2.9g / L.

[004...

Embodiment 2

[0050] According to the following steps, the active ingredient in the 7-ACA crystallization mother liquor produced by the enzymatic cleavage method is comprehensively recovered:

[0051] (1) Preparation of 7-ACA mother liquor concentrate

[0052] Take the enzymatic cleavage method after 7-ACA crystal separation to produce 20.0L of 7-ACA crystallization mother liquor, the concentration of 7-ACA in the mother liquor is 1.0g / L, the concentration of D-α-aminoadipic acid is 11.2g / L, and the concentration of CPC is 0.5g / L, pH5.16.

[0053] Slowly adjust the above-mentioned 7-ACA crystallization mother liquor with 15wt% sodium hydroxide solution until the solution is clear, and the pH is adjusted to 6.90, and then use a nanofiltration membrane with a molecular weight cut-off of 160 Daltons to store the 7-ACA crystallization mother liquor at 5-8°C Concentrate to 2.5L, in which the concentration of 7-ACA is 7.8g / L, the concentration of D-α-aminoadipic acid is 89.2g / L, and the concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com