Large-strain low-drive electric field relaxation and ferroelectric composite lead-free piezoelectric ceramic and preparation method thereof

A technology of electric lead-free ceramics and lead-free piezoelectric, which is applied in the field of composite piezoelectric ceramics, can solve the problems of poor piezoelectric performance, difficult application, excessive driving electric field, etc., and achieve the effect of reducing cost and difficulty of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

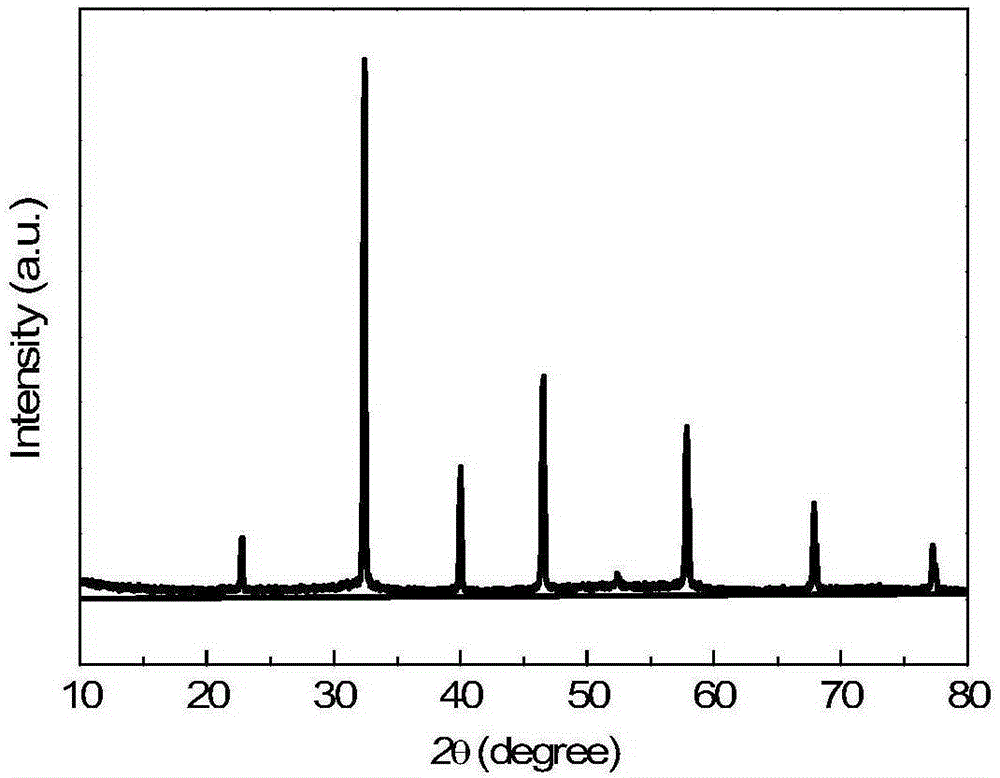

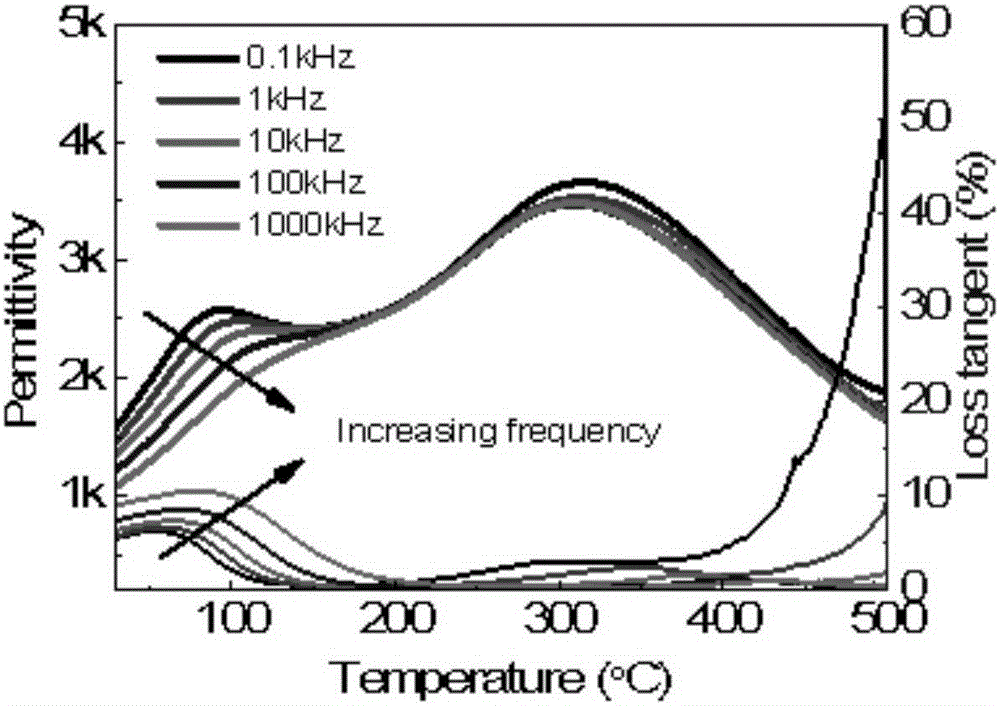

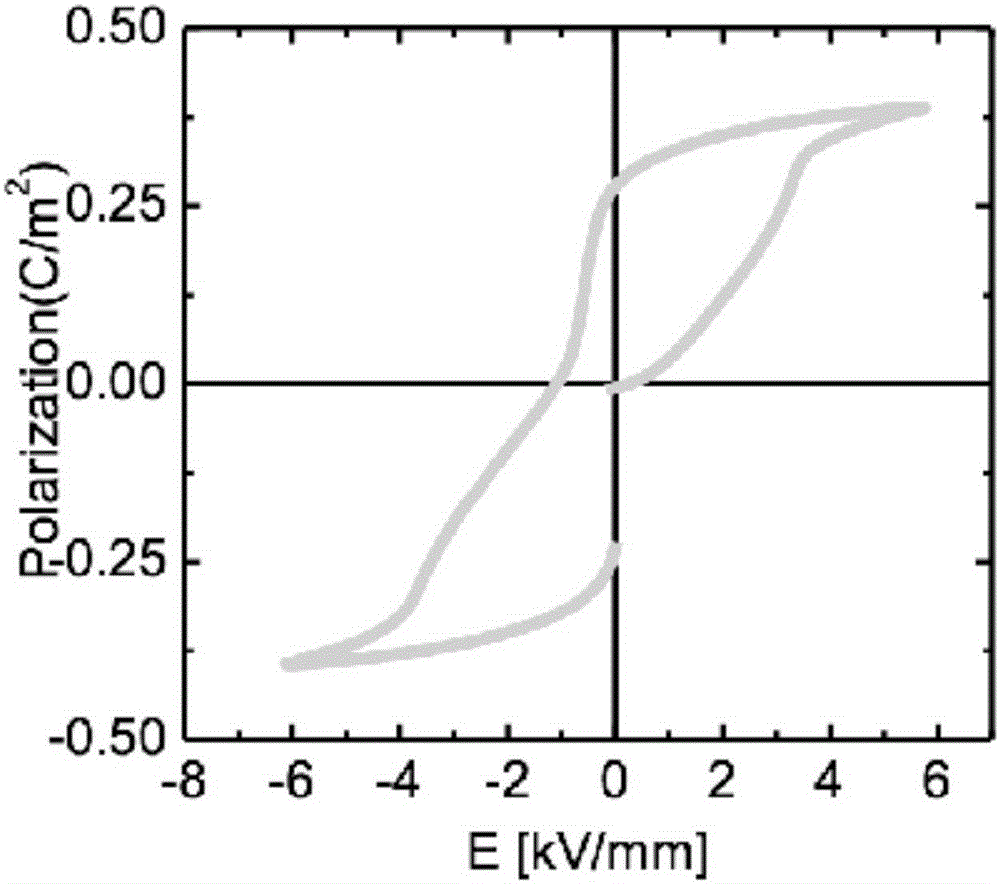

Embodiment 1

[0039] According to the general formula (1-x 1 -y 1 )Bi 0.5 Na 0.5 TiO 3 -x 1 Bi 0.5 K 0.5 TiO 3 -y 1 AgNbO 3 The indicated content of sodium bismuth titanate-potassium bismuth titanate-silver niobate ternary relaxation type lead-free piezoelectric ceramics is prepared, and the relaxation type ceramic powder A is prepared by the traditional solid-phase method. According to the general formula (1- z) Bi 0.5 Na 0.5 TiO 3 -zBaTiO 3 The sodium bismuth titanate-barium titanate ferroelectric ceramic powder B was prepared by the traditional solid-phase method; when x1=0.18, y1=0.02, z=0.06, A is 0.80Bi 0.5 Na 0.5 TiO 3 -0.18Bi 0.5 K 0.5 TiO 3 -0.02AgNbO 3 , B is 0.94Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 , Mix 20% volume B powder into 80% volume A powder, mix by ball milling, dry, granulate and dry press into flakes, and then sinter at 1120°C for 1 hour in an air atmosphere, the obtained The relaxo-ferroelectric composite ceramics, the surface was polished and the u...

Embodiment 2

[0041] According to the general formula (1-x 1 -y 1 )Bi 0.5 Na 0.5 TiO 3 -x 1 Bi 0.5 K 0.5 TiO 3 -y 1 AgNbO 3 The indicated content of sodium bismuth titanate-potassium bismuth titanate-silver niobate ternary relaxation type lead-free piezoelectric ceramics is prepared, and the relaxation type ceramic powder A is prepared by the traditional solid-phase method. According to the general formula (1- z) Bi 0.5 Na 0.5 TiO 3 -zBaTiO 3 The sodium bismuth titanate-barium titanate ferroelectric ceramic powder B was prepared by the traditional solid-phase method; when x1=0.20, y1=0.03, z=0.06, A is 0.77Bi 0.5 Na 0.5 TiO 3 -0.20Bi 0.5 K 0.5 TiO 3 -0.03AgNbO 3 , B is 0.94Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 , Mix 30% volume B powder into 80% volume A powder, mix by ball milling, dry, granulate and dry press into flakes, and then sinter at 1130 °C for 1 hour in an air atmosphere, the obtained The relaxo-ferroelectric composite ceramics, the surface was polished and the ...

Embodiment 3

[0043] According to the general formula (1-x 1 -y 1 )Bi 0.5 Na 0.5 TiO 3 -x 1 Bi 0.5 K 0.5 TiO 3 -y 1 AgNbO 3 The indicated content of sodium bismuth titanate-potassium bismuth titanate-silver niobate ternary relaxation type lead-free piezoelectric ceramics is prepared, and the relaxation type ceramic powder A is prepared by the traditional solid-phase method. According to the general formula (1- z) Bi 0.5 Na 0.5 TiO 3 -zBaTiO 3 The sodium bismuth titanate-barium titanate ferroelectric ceramic powder B was prepared by the traditional solid-phase method; when x1=0.21, y1=0.03, z=0.07, A is 0.76Bi 0.5 Na 0.5 TiO 3 -0.21Bi 0.5 K 0.5 TiO 3 -0.03AgNbO 3 , B is 0.93Bi 0.5 Na 0.5 TiO 3 -0.07BaTiO 3 , 30% volume B powder is mixed into 70% volume A powder, after ball milling mixing, drying, granulation and dry pressing into flakes, after sintering at 1140 ° C for 1 hour in an air atmosphere, the obtained The relaxo-ferroelectric composite ceramics, whose surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com