Foaming agent for low temperature-resistant soil pressure balance shield, and preparation method and application of foaming agent

A technology of earth pressure balance shield and foaming agent, which is applied in the field of foaming agent, can solve the problems of whitening of foaming agent, reducing the foaming rate of foaming agent, turbidity, etc., and achieves the reduction of adverse effects and good foam stability , The effect of high foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] The foaming agent for low-temperature-resistant earth pressure balance shield tunneling of the present invention, its preferred embodiment is:

[0013] The formula components and their weight percentages are: α-olefin sulfonate 2-4%, fatty alcohol polyoxyethylene ether sulfate 4-10%, coconut acid diethanolamide 1-2%, cocamidopropyl Betaine 0.5-1%, polyethylene glycol 0.5-2%, glycerin 0.1-0.5%, lauryl alcohol 0.05-0.3%, sodium chloride 0.1-0.5%, Cathone 0.05-0.15%, citric acid 0.05% ~0.2%, the balance water 79.35~91.65%.

[0014] The lauryl alcohol, α-olefin sulfonate and fatty fatty alcohol polyoxyethylene ether sulfate have a synergistic effect to enhance the foam stabilizing effect.

[0015] The preparation method of the foaming agent for the above-mentioned low temperature resistant earth pressure balance shield of the present invention, its preferred embodiment is:

[0016] Include steps:

[0017] Set the temperature of the first stainless steel mixing tank to 40...

Embodiment 1

[0032] In this embodiment, the foaming agent for low-temperature-resistant shield tunneling, the formula composition and its weight percentage are: 3% of α-olefin sulfonate, 5.5% of fatty alcohol polyoxyethylene ether sulfate, and 1.2% of coconut acid diethanolamide , Cocamidopropyl Betaine 0.9%, Polyethylene Glycol 1.5%, Glycerin 0.3%, Lauryl Alcohol 0.25%, Sodium Chloride 0.3%, Cathone 0.1%, Citric Acid 0.1%, Balance Water 86.85 %.

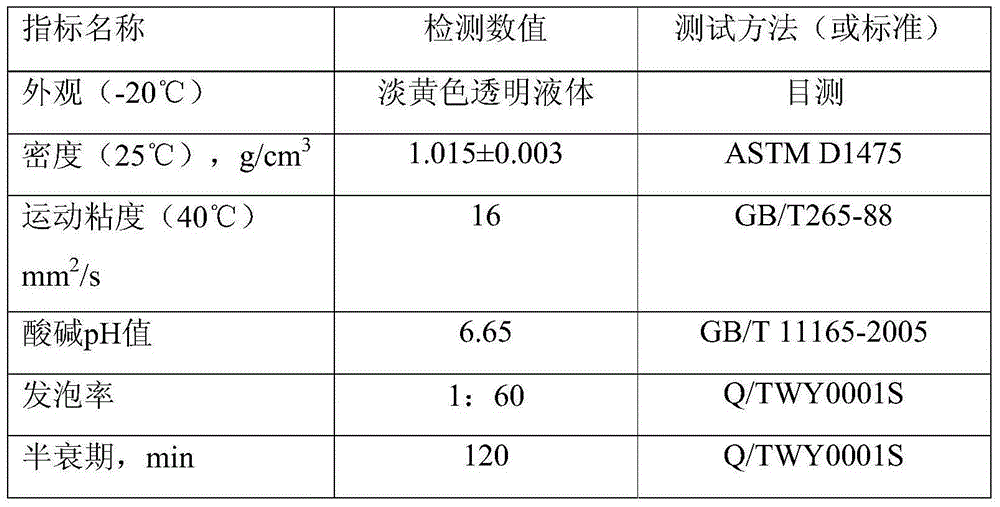

[0033] A foaming agent sample is obtained according to the foaming agent preparation process described in the present invention, and the foaming agent is diluted with water until the weight percentage of anionic surfactant in the foaming solution is 1.5%, and foaming is carried out at normal temperature and pressure. The foaming conditions are: the compressed air pressure is 0.4MPa, the gas flow rate is 10L / min, the pumping pressure of the foaming solution is 0.4MPa, and the solution flow rate is 12L / h. The physical and chemical indicators of t...

Embodiment 2

[0037] In this embodiment, the foaming agent for low-temperature-resistant shield tunneling, the formula composition and its weight percentage are: 4% of α-olefin sulfonate, 8% of fatty alcohol polyoxyethylene ether sulfate, and 1.5% of coconut acid diethanolamide , Cocamidopropyl Betaine 1.0%, Polyethylene Glycol 1.5%, Glycerin 0.3%, Lauryl Alcohol 0.05%, Sodium Chloride 0.3%, Cathone 0.1%, Citric Acid 0.1%, Balance Water 83.15 %.

[0038] A foaming agent sample is obtained according to the foaming agent preparation process described in the present invention, and the foaming agent is diluted with water until the weight percentage of anionic surfactant in the foaming solution is 1.5%, and foaming is carried out at normal temperature and pressure. The foaming conditions are: the compressed air pressure is 0.4MPa, the gas flow rate is 10L / min, the pumping pressure of the foaming solution is 0.4MPa, and the solution flow rate is 12L / h. The physicochemical index of this whipping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com