Ammonium paratungstate deep purification and impurity removal method

An advanced technology of ammonium paratungstate, applied in the field of tungsten smelting, can solve the problem of inability to remove potassium and sodium, and achieve the effect of obvious impurity removal, easy removal and good volatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

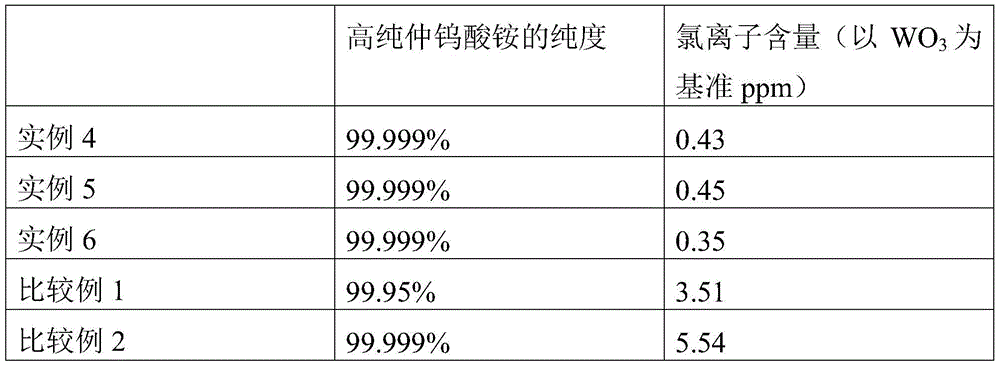

Examples

example 1

[0031] The zero-grade product of ammonium paratungstate conforming to the GBT10116-2007 standard is deeply purified to remove impurities to prepare high-purity ammonium paratungstate products.

[0032] Take the standard sample APT-0 product: WO 3 The content of the main metal impurities in the product is 89%, as shown in the following table:

[0033] Element K Na Mg Ga Cu Al content (in WO 3 as the base ppm) 10 9.8 5 8.5 3 4

[0034] The ammonium paratungstate product is converted into a tungstic acid solution for use through acidification-filtration-dissolution, among which H 2 WO 4 WO in solution 3The concentration is 230g / L. Activate the K6-4 resin with hydrochloric acid 1.8 times the volume of the resin, and the concentration of hydrochloric acid is 3mol / L. Use a pump to send the tungstic acid solution into the ion exchange column at a flow rate of 20-30ml / s. The specifications of the exchange column are: 10cm in diameter and 200cm i...

example 2

[0039] The zero-grade product of ammonium paratungstate conforming to the GBT10116-2007 standard is deeply purified to remove impurities to prepare high-purity ammonium paratungstate products.

[0040] Take the standard sample APT-1 product: WO 3 Content of 88.5%, the content of main metal impurities in the product is shown in the table below:

[0041] Element K Na Mg Ga Cu Al content (in WO 3 as the base ppm) 15 14.7 6.8 9.8 5.0 6.2

[0042] The ammonium paratungstate product is converted into a tungstic acid solution for use through acidification-filtration-dissolution, among which H 2 WO 4 WO in solution 3 The concentration is 240g / L. Activate the K6-4 resin with hydrochloric acid 1.8 times the volume of the resin, and the concentration of hydrochloric acid is 3mol / L. Use a pump to send the tungstic acid solution into the ion exchange column at a flow rate of 20-30ml / s. The specifications of the exchange column are: 10cm in diameter a...

example 3

[0047] The zero-grade product of ammonium paratungstate conforming to the GBT10116-2007 standard is deeply purified to remove impurities to prepare high-purity ammonium paratungstate products.

[0048] Take the standard sample APT-1 product: WO 3 Content of 88.5%, the content of main metal impurities in the product is shown in the table below:

[0049] Element K Na Mg Ga Cu Al content (in WO 3 as the base ppm) 15 14.7 6.8 9.8 5.0 6.2

[0050] The ammonium paratungstate product is converted into a tungstic acid solution for use through acidification-filtration-dissolution, among which H 2 WO 4 WO in solution 3 The concentration is 240g / L. Activate the K6-4 resin with hydrochloric acid 1.8 times the volume of the resin, and the concentration of hydrochloric acid is 3mol / L. Use a pump to send the tungstic acid solution into the ion exchange column at a flow rate of 20-30ml / s. The specifications of the exchange column are: 10cm in diameter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com