Tooling and method for slantly lifting piston assembly

A piston component and tooling technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inability to use lifting tooling, lifting piston components, and lifting heights that cannot meet the aforementioned requirements, and achieve low manufacturing costs and methods Easy operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

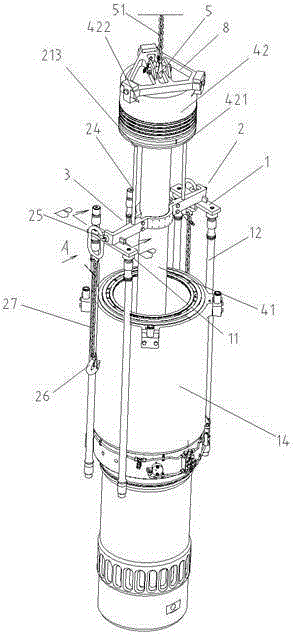

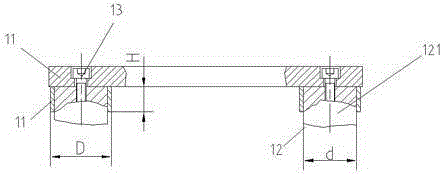

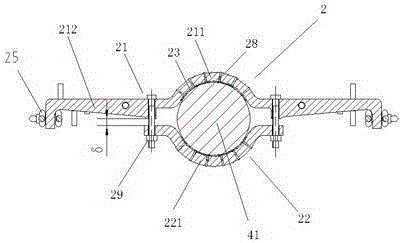

[0030] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a pair of horizontal plates 1, a piston rod clamp ring set 2 and an upper beam 3, the two ends of the lower surface of the horizontal plate 1 are vertically welded to the circular tube 11 respectively, and the height H of the circular tube is less than the outer diameter D of the circular tube. The inner diameter d of the circular tube contains the outer diameter of the upper end of the cylinder head stud 121, and the two ends of the horizontal plate 1 are fixedly connected to the upper end of the cylinder head stud 12 inserted into the circular tube 11 by the fastening screw 13 to form a goal-shaped frame. Such a structure makes the connection between the transverse plate 1 and the cylinder head stud 12 firm, and can prevent the fastening screw 13 from being subjected to shearing force.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com