Self-circulating micro-addition device

A technology of adding devices and self-circulation, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve problems such as fluctuations in packaging quality and instability, and achieve the effects of saving equipment maintenance costs, ingenious structure, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

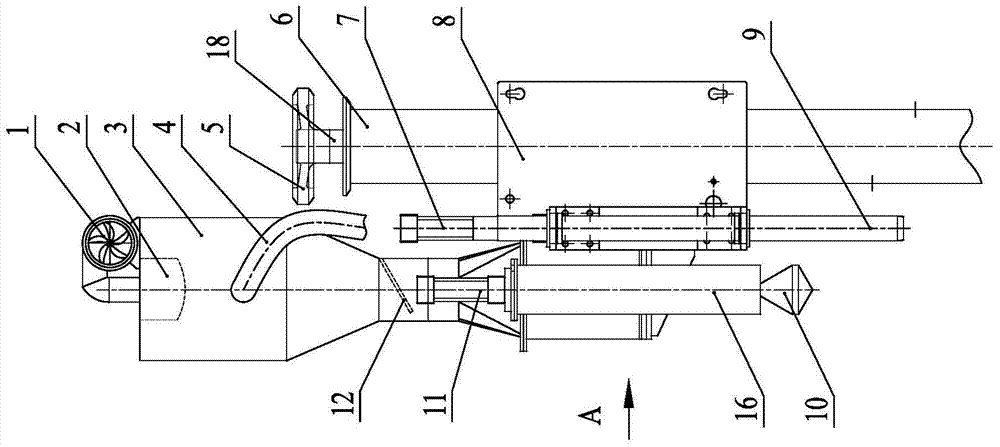

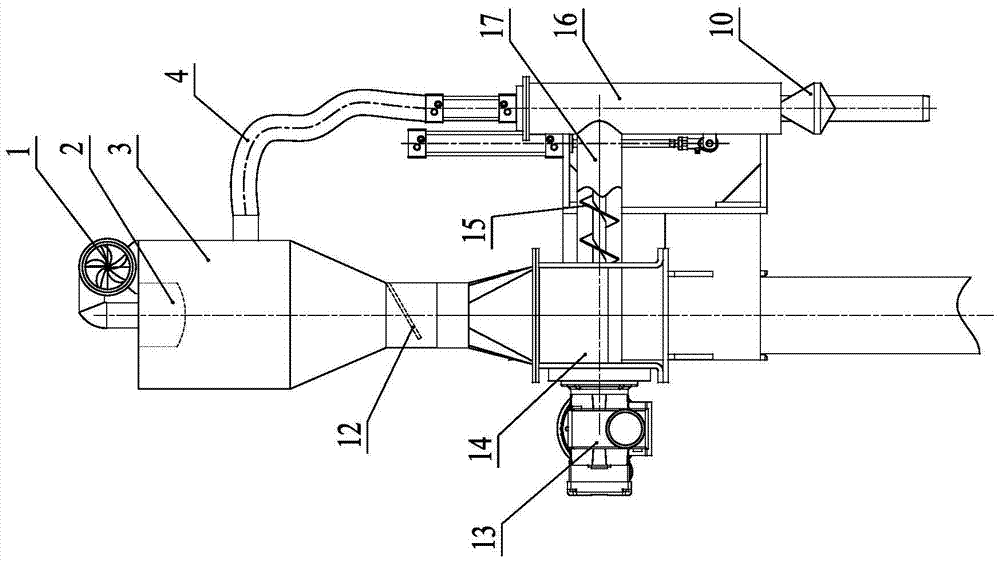

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] As shown in the figure: the self-circulating micro-addition device in the embodiment is mainly composed of an air pump 1, a filter element 2, a vacuum storage bin 3, a connecting hose 4, an adjustment hand wheel 5, a frame 6, a reclaiming cylinder 7, and a support 8 , Feed pipe 9, cut-off valve 10, cut-off cylinder 11, live valve 12, motor 13, feed box 14, feeding auger 15, feeding pipe 16, delivery pipeline 17 and screw 18 etc. composition.

[0014] Such as figure 1 , figure 2 As shown, the support 8 is connected on the frame 6 by a lifting adjustment mechanism; the feed box 14 is installed on the support 8, and the vacuum storage bin 3 is arranged above the feed box 14, and the feed box 14 The feed port is communicated with the discharge port of the vacuum storage bin 3; an air pump 1 is installed on the vacuum storage bin 3, and a filter element 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com