Flow guide pipe for vacuum filling and preparation method thereof

A technology of vacuum perfusion and diversion tube, which is applied in the field of vacuum perfusion diversion tube and its preparation, which can solve the problems of residual resin and imprints, etc., and achieve high production efficiency, uniform material and good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

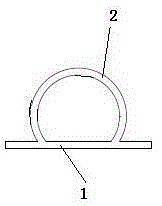

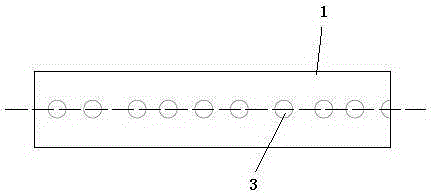

[0025] Such as figure 1 As shown, a vacuum perfusion guide tube includes a guide tube main body 2. The guide tube main body 2 described in the present invention is a pipe with a cylindrical structure, and then from one end of the pipe with a cylindrical structure along the length of the pipe The pipe body cut out in the direction, this pipe body is the diversion pipe main body 2 of the present invention. The description above is split to facilitate the understanding of those skilled in the art. In fact, the bottom plate 1 and the main body of the draft tube 2 in the present invention are integrally formed, and the bottom plate 1 and the main body of the draft tube 2 form a whole with a hollow interior. Such as figure 2 As shown, the bottom plate 1 is equidistantly provided with a plurality of diversion holes 3 along the extending direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com