engine assembly table

A technology for assembly tables and engines, applied to workbenches, manufacturing tools, etc., can solve problems such as potential safety hazards, existence of production processes, failure of stoppers, etc., and achieve the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

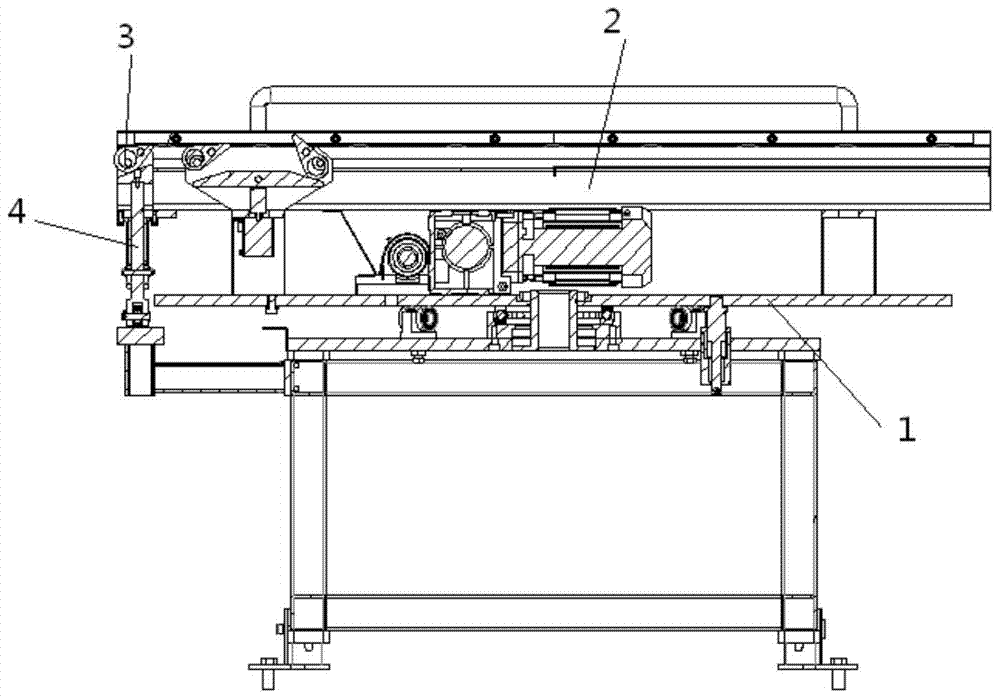

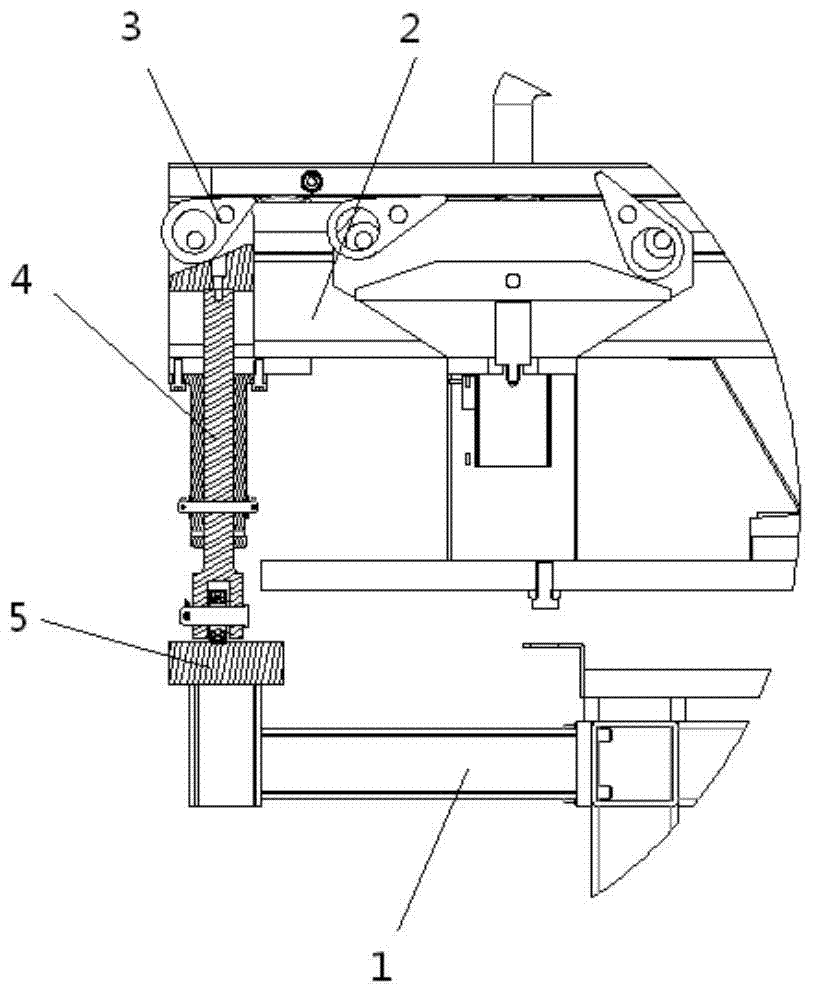

[0025] Such as Figure 1-5 As shown, an engine assembly platform provided by the embodiment of the present invention includes a base 1 and a turntable 2, and the turntable 2 is rotatably arranged on the top surface of the base 1, and also includes a cam 3, a sliding column 4 and a concave-convex Part 5, the cam 3 is rotatably connected to the turntable 2, the concave-convex part 5 is set on the base 1, the sliding column 4 is slidably connected to the rotary table 2, and the bottom end of the sliding column 4 is rollingly connected to the concave-convex surface of the concave-convex part 5 , the top of the sliding column 4 is a wedge 6, and the slope of the wedge 6 abuts the cam 3; on the rotation stroke of the cam 3, it has a position where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com